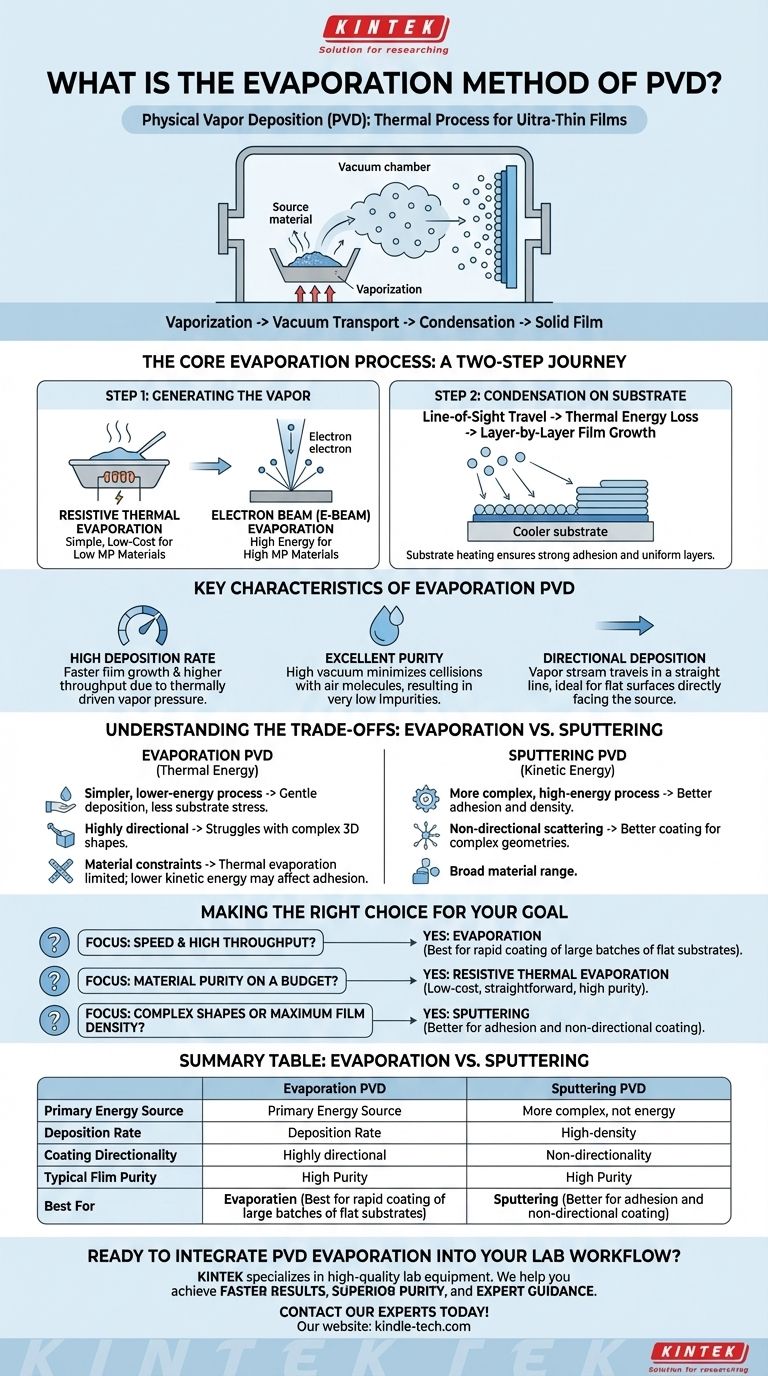

In physical vapor deposition (PVD), the evaporation method is a process where a source material is heated within a high vacuum chamber until it vaporizes. These gaseous atoms or molecules then travel through the vacuum and condense onto a cooler object, known as the substrate, forming an ultra-thin, solid film.

The core principle of evaporation PVD is its simplicity and speed. By essentially boiling a material and allowing it to condense elsewhere, it provides a fast and highly pure method for creating thin films, distinguishing it from other PVD techniques that rely on kinetic energy instead of thermal energy.

The Core Evaporation Process: A Two-Step Journey

The entire process is elegant in its directness, consisting of two fundamental stages that occur inside a high-vacuum environment.

Step 1: Generating the Vapor

The process begins by heating a source material, often a metal, until it reaches a temperature where it begins to evaporate, turning directly into a gas. This is typically accomplished through one of two common methods:

- Resistive Thermal Evaporation: The source material is placed in a "boat" or on a filament made of a high-melting-point material. A strong electrical current is passed through this boat, heating it resistively and, in turn, evaporating the source material. This method is simple, affordable, and ideal for materials with relatively low melting points.

- Electron Beam (E-Beam) Evaporation: A high-energy beam of electrons is focused on the source material. The kinetic energy of the electrons is converted to thermal energy upon impact, heating a very localized area of the material to its evaporation point. This allows for the deposition of materials with very high melting points.

Step 2: Condensation on the Substrate

Once in a gaseous state, the evaporated atoms travel in a straight, "line-of-sight" path through the vacuum. When they encounter the cooler substrate (the object being coated), they lose their thermal energy and condense back into a solid state, building up layer-by-layer to form a uniform film.

Proper heating of the substrate itself is often critical to ensure the deposited film adheres strongly and forms a uniform, well-structured layer.

Key Characteristics of Evaporation PVD

Understanding the inherent traits of the evaporation process is key to knowing when to use it. Its advantages over other methods, like sputtering, are significant in specific contexts.

High Deposition Rate

A primary advantage of evaporation is its speed. Because it relies on thermally driven vapor pressure, it can produce a high flux of material, leading to much faster film growth and higher throughput compared to sputtering.

Excellent Purity

The high-vacuum environment is crucial, as it minimizes the chance for gas molecules from the air to collide with the vapor stream and become trapped in the growing film. This results in coatings with very low impurity levels and fewer adsorbed gases.

Directional Deposition

The vapor stream travels in a direct line from the source to the substrate. This directionality is excellent for achieving uniform coatings on flat surfaces that directly face the source.

Understanding the Trade-offs: Evaporation vs. Sputtering

No single method is universally superior. The choice to use evaporation is a decision based on specific goals and priorities, which often means comparing it to sputtering, the other major PVD technique.

The Advantage of Simplicity and Energy

Evaporation is fundamentally a lower-energy process than sputtering. Atoms gently leave the source and condense on the substrate. This gentleness can be an advantage, as it induces less stress and heat in the substrate.

The Limitation of Line-of-Sight

The highly directional nature of evaporation is also its main drawback. It struggles to evenly coat complex, three-dimensional shapes or the sides of features, as any area not in the direct line-of-sight of the source will receive little to no coating. Sputtering, where atoms are scattered more randomly, is far better for coating complex geometries.

Constraints on Materials and Adhesion

While E-beam evaporation can handle high-temperature materials, the simpler thermal evaporation is limited to materials that can be easily vaporized. Furthermore, because the depositing atoms have lower kinetic energy, the resulting film's adhesion and density can sometimes be lower than what is achievable with high-energy sputtering processes.

Making the Right Choice for Your Goal

Selecting the correct PVD method requires a clear understanding of your project's most critical outcome.

- If your primary focus is speed and high throughput: The high deposition rates of evaporation make it the superior choice for rapidly coating large batches of relatively flat substrates.

- If your primary focus is material purity on a budget: Resistive thermal evaporation offers a low-cost, straightforward process that results in exceptionally pure films.

- If your primary focus is coating complex shapes or maximizing film density: Sputtering is often a better alternative due to its non-directional nature and the higher energy of its depositing particles, which improves adhesion and film integrity.

Ultimately, understanding the fundamental difference between boiling a material (evaporation) and kinetically bombarding it (sputtering) is the key to selecting the right PVD technology for your specific goal.

Summary Table:

| Feature | Evaporation PVD | Sputtering PVD |

|---|---|---|

| Primary Energy Source | Thermal (Heat) | Kinetic (Bombardment) |

| Deposition Rate | High | Lower |

| Coating Directionality | Line-of-Sight | Non-Directional |

| Typical Film Purity | High | Good |

| Best For | Flat surfaces, high throughput | Complex 3D shapes, superior adhesion |

Ready to Integrate PVD Evaporation into Your Lab Workflow?

Choosing the right thin-film deposition technique is critical for your research and production outcomes. At KINTEK, we specialize in providing high-quality lab equipment, including PVD systems tailored to your specific needs.

We help you achieve:

- Faster Results: Leverage high deposition rates to accelerate your R&D and production cycles.

- Superior Purity: Ensure the integrity of your coatings with our reliable evaporation systems.

- Expert Guidance: Our team will help you select the perfect equipment, whether your priority is speed for flat substrates or versatility for complex geometries.

KINTEK is your trusted partner for all laboratory equipment and consumables. Let's discuss how a PVD evaporation system can enhance your capabilities.

Contact our experts today for a personalized consultation!

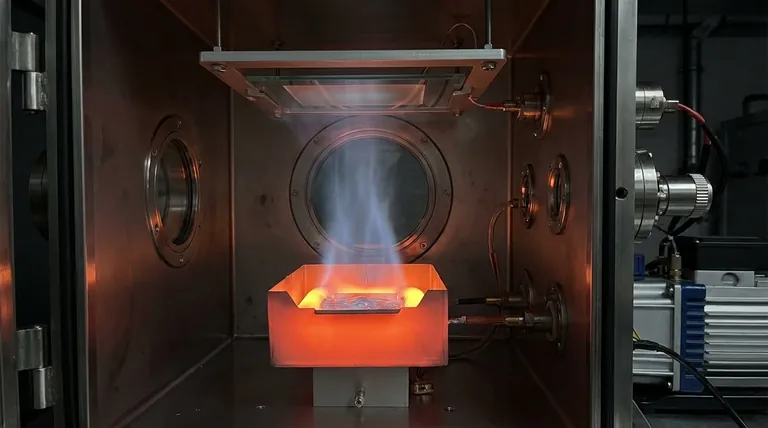

Visual Guide

Related Products

- Molybdenum Tungsten Tantalum Evaporation Boat for High Temperature Applications

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

People Also Ask

- What is the widely used boat made of in thermal evaporation? Choosing the Right Material for High-Purity Deposition

- What is thermal evaporation technique thin film deposition? A Guide to Simple, Cost-Effective PVD

- What is the meaning of thermal evaporation? A Guide to Simple, Cost-Effective Thin Film Coating

- What is thermal evaporation used to deposit? A Guide to Metals, Compounds, and Key Applications

- What is the process of thermal evaporation in PVD? A Step-by-Step Guide to Thin Film Deposition