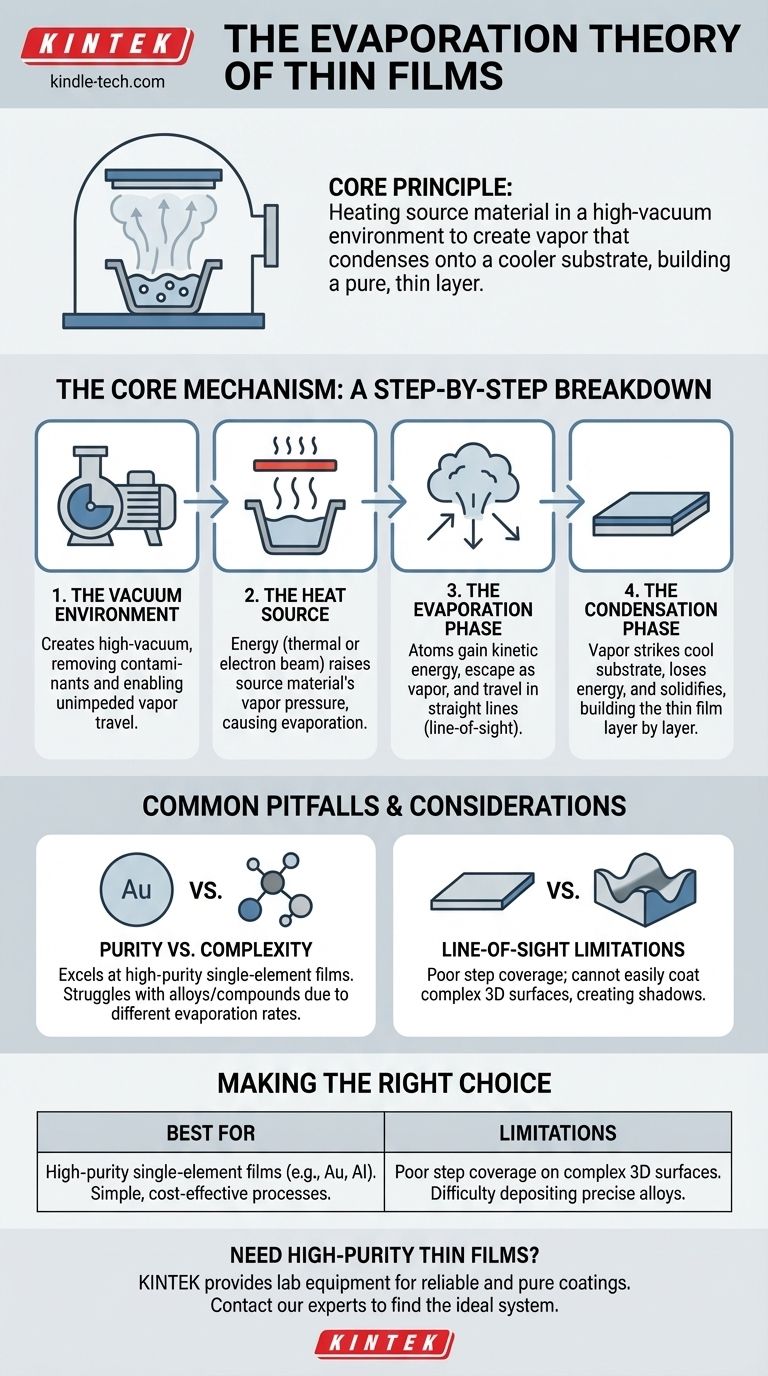

At its core, the evaporation theory of thin films describes a process where a source material is heated until it turns into a vapor within a high-vacuum chamber. This vapor then travels unimpeded and condenses onto a cooler surface, known as a substrate, building up a highly pure, thin layer of the material atom by atom. It is a fundamental technique within the family of Physical Vapor Deposition (PVD) methods.

The central principle is straightforward: use heat to "boil" a material in a vacuum, allowing its vapor to travel in a straight line and solidify onto a target. This process is analogous to water vapor from a boiling pot condensing on a cool lid above it.

The Core Mechanism: A Step-by-Step Breakdown

To truly understand the theory, it's best to break the process down into its distinct, sequential stages. Each step is critical for achieving a high-quality film.

The Vacuum Environment

The entire process begins by creating a high-vacuum environment. This removes air and other unwanted gas molecules from the chamber.

This vacuum is essential for two reasons: it prevents the hot source material from reacting with contaminants, and it clears the path for evaporated atoms to travel to the substrate.

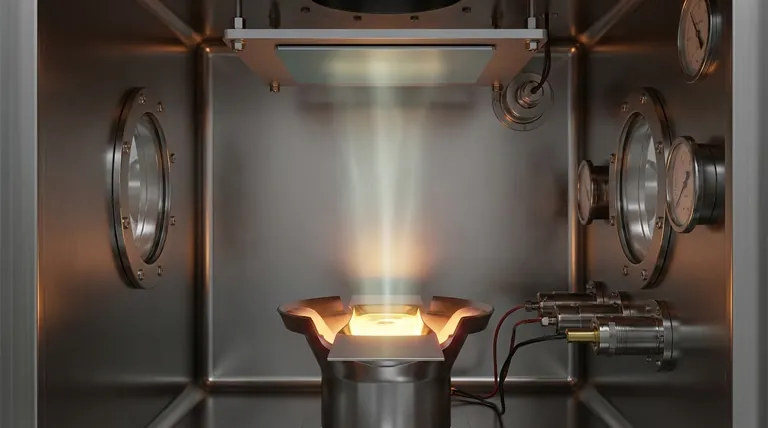

The Heat Source

Energy is applied to the source material, typically held in a container called a crucible. This energy is usually thermal, generated by resistance heating or an electron beam.

The heat must be sufficient to raise the material's vapor pressure significantly, providing the energy needed for its atoms to escape the solid or liquid state and enter a gaseous phase.

The Evaporation Phase

As the source material heats up, its atoms gain enough kinetic energy to evaporate. They are liberated from the source as a vapor.

Inside the vacuum, these vaporized atoms travel in straight lines, a characteristic known as line-of-sight travel.

The Condensation Phase

When the vaporized atoms strike the cooler substrate, they rapidly lose their energy and condense back into a solid state.

This process of condensation builds the thin film, layer by layer, on the substrate's surface. The final thickness of the film is controlled by the rate of evaporation and the duration of the process.

Common Pitfalls and Considerations

While effective, the simplicity of evaporation carries specific trade-offs that are critical to understand. This method is not universally applicable for all materials or film structures.

Purity vs. Complexity

Evaporation excels at creating very high-purity films from a single element, as the vacuum prevents contamination.

However, it struggles with alloys or compound materials. Different elements within a compound will evaporate at different rates based on their unique vapor pressures, making it difficult to maintain the correct stoichiometry in the final film.

Line-of-Sight Limitations

Because the vapor travels in a straight line, evaporation has poor step coverage. It cannot easily coat complex, three-dimensional surfaces with undercuts or deep trenches.

Areas not in the direct line of sight of the source will receive little to no deposition, creating "shadows" on the substrate.

Making the Right Choice for Your Goal

Understanding the core principles of evaporation allows you to determine when it is the most appropriate deposition method for your objective.

- If your primary focus is high-purity, single-element films: Evaporation is an excellent, cost-effective choice, particularly for materials like aluminum, gold, or chromium in applications like mirror coatings or electrical contacts.

- If your primary focus is coating a complex 3D object uniformly: You should consider alternative PVD methods, such as sputtering, which provide superior step coverage.

- If your primary focus is depositing a precise alloy or compound: Advanced evaporation techniques (co-evaporation) or sputtering are necessary to control the film's final composition accurately.

Ultimately, thermal evaporation is a foundational thin-film technique valued for its simplicity and ability to produce exceptionally pure films.

Summary Table:

| Process Stage | Key Function | Consideration |

|---|---|---|

| Vacuum Environment | Removes contaminants, enables straight-line vapor travel. | Essential for purity and process efficiency. |

| Heat Source | Provides energy to vaporize the source material. | Must overcome the material's vapor pressure. |

| Evaporation | Atoms enter the gas phase and travel to the substrate. | Travel is line-of-sight, creating shadowing effects. |

| Condensation | Vapor atoms solidify on the substrate, building the film. | Determines film thickness, adhesion, and quality. |

| Best For | Limitations | |

| High-purity single-element films (e.g., Au, Al). | Poor step coverage on complex 3D surfaces. | |

| Simple, cost-effective deposition processes. | Difficulty depositing precise alloys or compounds. |

Need to deposit high-purity thin films for your research or production?

The evaporation theory is the foundation for reliable and pure coatings. At KINTEK, we specialize in providing the lab equipment and consumables, including evaporation systems and crucibles, to bring this theory to life in your laboratory. Whether you're working on mirror coatings, electrical contacts, or basic research, our solutions are designed for precision and performance.

Let's discuss your specific thin-film deposition needs. Contact our experts today to find the ideal system for your application!

Visual Guide

Related Products

- Molybdenum Tungsten Tantalum Evaporation Boat for High Temperature Applications

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Evaporation Boat for Organic Matter

- Hemispherical Bottom Tungsten Molybdenum Evaporation Boat

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

People Also Ask

- What materials are used in thermal evaporation? From Metals to Dielectrics for Thin-Film Coating

- What is the thermal evaporation method for thin films? A Guide to High-Purity PVD Coating

- What are the applications of electron beams? From Nanoscale Imaging to Industrial Manufacturing

- What are the uses of thermal evaporation? Essential for Electronics, Optics & Decorative Finishes

- What is the pressure for thermal evaporation? Achieve High-Purity Thin Films with Optimal Vacuum

- What is the process of vacuum deposition? Achieve Atomic-Level Precision Coatings

- What is the process of thermal evaporation? A Guide to Simple, Cost-Effective Thin-Film Deposition

- What is thermal effect via evaporation? A Simple Guide to Thin-Film Deposition