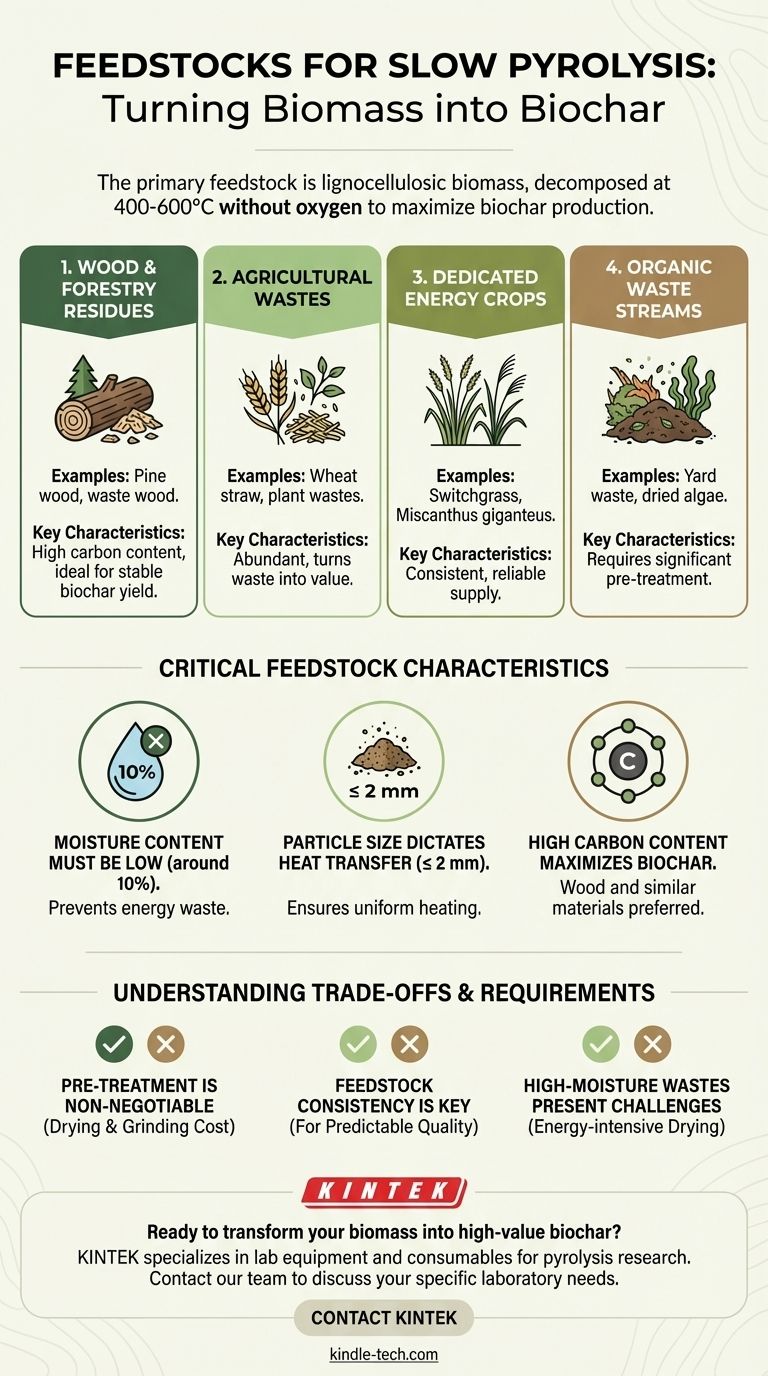

The primary feedstock for slow pyrolysis is lignocellulosic biomass, which includes a wide range of organic materials like wood, agricultural residues, and dedicated energy crops. This process is specifically designed to decompose this type of organic matter at low temperatures (400-600°C) in the absence of oxygen, maximizing the production of a solid, carbon-rich product known as biochar.

The suitability of a feedstock for slow pyrolysis depends less on its specific source and more on its physical and chemical properties. The ideal material is one with low moisture content and high carbon content that has been size-reduced to ensure efficient conversion into biochar.

The Core Feedstock Categories

Slow pyrolysis is versatile, but the most effective feedstocks fall into several key groups. These materials are chosen for their high lignocellulose content—the structural material that makes up the cell walls of plants.

Wood and Forestry Residues

This is the most common and well-suited category for slow pyrolysis. Materials like pine wood and other waste woods are ideal because their high carbon content and dense structure lead to a high yield of stable biochar.

Agricultural Wastes

Residues from farming are a significant feedstock source. This includes materials like wheat straw and other plant wastes left over after harvesting. Using these materials turns a potential waste stream into a valuable product.

Dedicated Energy Crops

Certain plants are grown specifically for their potential as biomass feedstock. Fast-growing grasses such as switchgrass (Panicum virgatum) and Miscanthus giganteus provide a consistent and reliable source for pyrolysis operations.

Organic Waste Streams

A variety of other organic wastes can be processed, though they may require more preparation. This includes yard waste (green waste) and even dried algae. High-moisture wastes like sludge can be used, but only after significant pre-treatment.

Critical Feedstock Characteristics for Success

Simply having the right type of material is not enough. For slow pyrolysis to be efficient and produce a quality product, the feedstock must be prepared to meet specific criteria.

Moisture Content Must Be Low

The ideal feedstock should have a moisture content of around 10%. If the moisture is too high, the process wastes energy creating steam instead of decomposing the material, reducing overall efficiency. Materials with high moisture content must be dried first.

Particle Size Dictates Heat Transfer

Efficient pyrolysis requires uniform heating. To achieve this, feedstock must be size-reduced to small particles, typically up to 2 mm. This small size ensures that heat penetrates each particle evenly and completely during its residence time in the reactor.

High Carbon Content Maximizes Biochar

Slow pyrolysis is fundamentally a carbonization process. Feedstocks with a naturally high carbon content, such as wood, are preferred because they directly translate into a higher yield of the primary desired product: solid biochar.

Understanding the Trade-offs and Requirements

While the list of potential feedstocks is long, the operational reality involves significant pre-processing. Failing to account for this is a common pitfall.

Pre-treatment is Non-negotiable

The requirements for low moisture and small particle size are not suggestions; they are operational necessities. The energy and cost associated with drying and grinding the raw feedstock must be factored into the overall economic viability of a pyrolysis plant.

Feedstock Consistency is Key

Using a consistent and homogenous feedstock leads to a predictable and high-quality biochar. While a reactor can process mixed wastes, the resulting biochar may have inconsistent properties, which can be problematic for certain applications like agricultural soil amendment.

High-Moisture Wastes Present a Challenge

Materials like food waste or sewage sludge can technically be used as feedstock. However, their extremely high water content makes the required drying process so energy-intensive that it can render the entire operation economically unfeasible without a very cheap source of heat.

Making the Right Choice for Your Goal

The best feedstock is the one that aligns with your primary objective and available resources.

- If your primary focus is high-quality biochar for agriculture: Use dense, woody biomass or high-lignin agricultural residues like straw, ensuring proper drying and grinding.

- If your primary focus is waste valorization: Utilize readily available green waste or crop residues, but invest heavily in the pre-treatment systems needed to ensure consistency.

- If your primary focus is a dedicated energy system: Cultivate energy crops like switchgrass to guarantee a consistent supply with predictable characteristics.

Ultimately, successful slow pyrolysis depends on preparing the right material to achieve a specific, high-value outcome.

Summary Table:

| Feedstock Category | Examples | Key Characteristics |

|---|---|---|

| Wood & Forestry Residues | Pine wood, waste wood | High carbon content, ideal for biochar yield |

| Agricultural Wastes | Wheat straw, plant residues | Abundant, turns waste into value |

| Dedicated Energy Crops | Switchgrass, Miscanthus | Consistent, reliable supply |

| Organic Waste Streams | Yard waste, dried algae | Requires significant pre-treatment |

Ready to transform your biomass into high-value biochar? The right feedstock preparation is critical to your success. KINTEK specializes in lab equipment and consumables for pyrolysis research and development. Our experts can help you select the right tools to analyze feedstock properties like moisture and carbon content, ensuring your process is efficient and your biochar quality is exceptional. Contact our team today to discuss your specific laboratory needs and how we can support your pyrolysis projects.

Visual Guide

Related Products

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

- Vertical Laboratory Tube Furnace

- Rotary Tube Furnace Split Multi Heating Zone Rotating Tube Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

People Also Ask

- What is the primary function of quartz tubes in halide electrolyte synthesis? Ensure Purity & Precise Stoichiometry

- What is the function of quartz tubes and vacuum sealing systems? Secure Your High-Purity Solid Solution Synthesis

- Why are quartz tubes preferred for chromium powder combustion? Superior Heat Resistance & Optical Clarity

- What is the technical value of using a quartz tube reaction chamber for static corrosion testing? Achieve Precision.

- What are the primary functions of high-precision tube furnaces in graphene growth? Achieve Defect-Free GS Synthesis