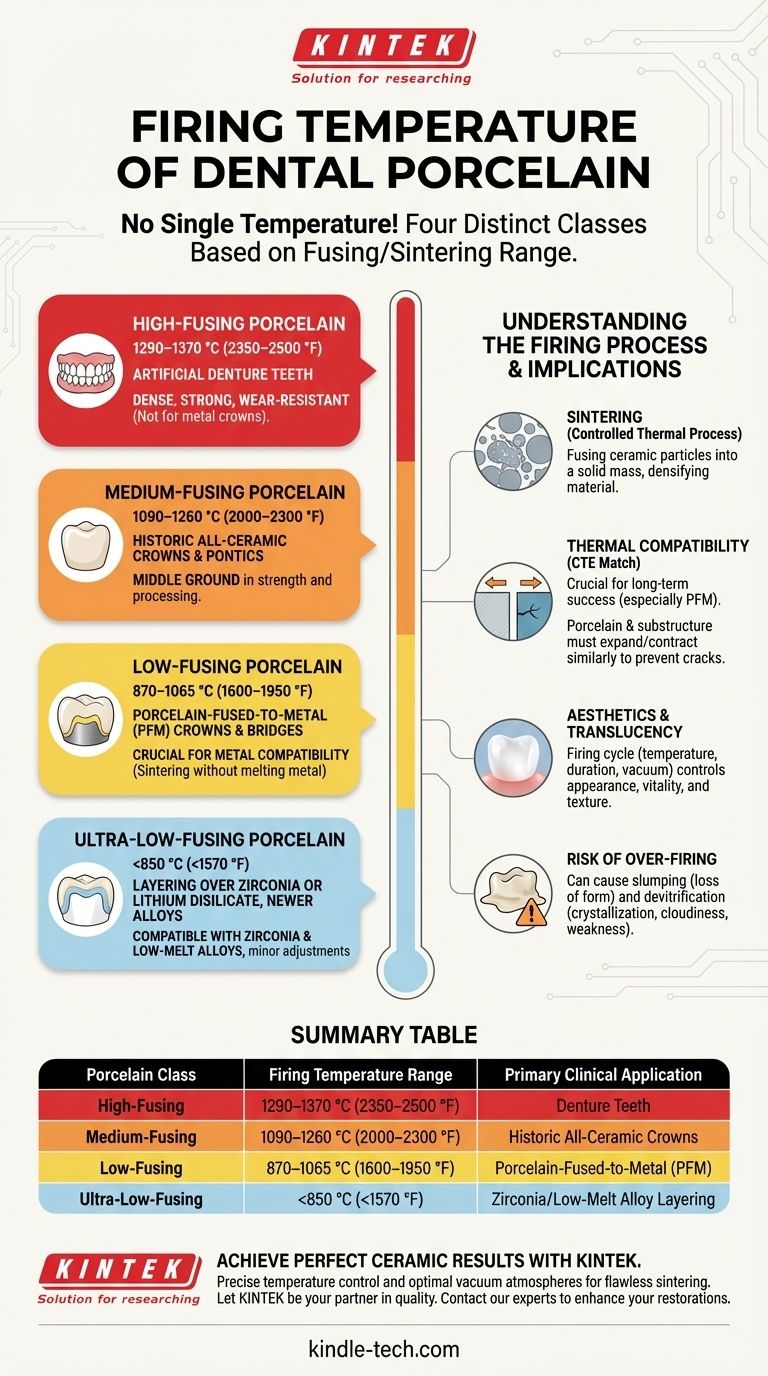

The quick answer is there is no single firing temperature for dental porcelain. Instead, dental porcelains are categorized into four distinct classes based on their fusing, or firing, temperatures, which range from under 850°C to over 1300°C. This classification is critical as it dictates the material's properties and its intended clinical application.

The specific firing temperature of a dental porcelain is not just a processing detail; it is the defining characteristic that determines its compatibility with metal or zirconia substructures, its final physical strength, and its aesthetic outcome.

The Classification of Dental Porcelains by Firing Temperature

The temperature at which a porcelain powder fuses into a solid mass—a process called sintering—is its most important attribute. This process allows the manufacturer to control the material's final properties.

High-Fusing Porcelain (1290–1370 °C / 2350–2500 °F)

This type of porcelain undergoes sintering at the highest temperatures. It is primarily used for manufacturing artificial denture teeth.

The high heat creates a very dense, strong, and wear-resistant material, ideal for the functional demands placed on dentures. It is not used for crowns that bond to metal, as these temperatures would melt the underlying alloy.

Medium-Fusing Porcelain (1090–1260 °C / 2000–2300 °F)

Medium-fusing porcelains were historically used for some all-ceramic crowns and bridgework (pontics).

While less common today with the advent of newer materials, they occupy a middle ground in terms of strength and processing requirements.

Low-Fusing Porcelain (870–1065 °C / 1600–1950 °F)

This is the most common category for creating the aesthetic layer on porcelain-fused-to-metal (PFM) crowns and bridges.

Its lower firing temperature is crucial because it allows the porcelain to be fused to the metal substructure without melting or distorting the metal. This compatibility is the entire basis for PFM restoration success.

Ultra-Low-Fusing Porcelain (<850 °C / <1570 °F)

Developed more recently, ultra-low-fusing porcelains are designed for compatibility with newer dental alloys that have lower melting points.

They are also used for layering over high-strength ceramic cores like zirconia or lithium disilicate, and for making minor additions or stain/glaze adjustments without risking distortion of the existing restoration.

Understanding the Firing Process and Its Implications

Firing porcelain is not simply melting. It is a controlled thermal process called sintering, where individual ceramic particles fuse at their contact points, densifying the material and removing porosity.

The Role of Thermal Compatibility

The single most important factor in long-term success, especially for PFM restorations, is thermal compatibility. The porcelain and the underlying metal must expand and contract at very similar rates when heated and cooled.

If the coefficient of thermal expansion (CTE) between the two materials does not match, stress will build up during cooling after firing, leading to cracks and fractures.

Aesthetics and Translucency

The firing cycle directly impacts the final appearance of the restoration. The temperature, duration, and use of a vacuum atmosphere all control the material's translucency, vitality, and surface texture.

Incorrect firing can result in a material that looks opaque, lifeless, or has a rough, unpleasing surface.

The Risk of Over-Firing

Applying too much heat or firing for too long can be destructive. Over-firing causes the porcelain to slump, losing the carefully sculpted anatomical form.

It can also lead to devitrification, where the glass matrix begins to crystallize, making the porcelain cloudy and weak. This damage is irreversible.

How to Select the Right Porcelain for Your Goal

Choosing the correct porcelain class is dictated entirely by the type of restoration you are creating. The underlying material is the determining factor.

- If your primary focus is a Porcelain-Fused-to-Metal (PFM) crown: You must use a low-fusing porcelain to ensure the temperature does not damage the metal substructure and that the CTE is compatible.

- If your primary focus is layering over a Zirconia core: You must use an ultra-low-fusing porcelain specifically formulated with a CTE that matches that of the zirconia framework.

- If your primary focus is manufacturing denture teeth: You must use high-fusing porcelain to achieve the necessary strength, density, and wear resistance for a removable prosthesis.

Understanding these temperature-defined categories is fundamental to producing durable, aesthetic, and clinically successful ceramic restorations.

Summary Table:

| Porcelain Class | Firing Temperature Range | Primary Clinical Application |

|---|---|---|

| High-Fusing | 1290–1370 °C (2350–2500 °F) | Denture Teeth |

| Medium-Fusing | 1090–1260 °C (2000–2300 °F) | Historic All-Ceramic Crowns |

| Low-Fusing | 870–1065 °C (1600–1950 °F) | Porcelain-Fused-to-Metal (PFM) |

| Ultra-Low-Fusing | <850 °C (<1570 °F) | Zirconia/Low-Melt Alloy Layering |

Achieve Perfect Ceramic Results with the Right Equipment

Selecting the correct dental porcelain is only half the battle. Consistent, precise firing cycles are critical for clinical success. KINTEK specializes in high-performance dental furnaces designed for the exacting demands of modern laboratories.

Our range of furnaces ensures precise temperature control and optimal vacuum atmospheres for flawless sintering of all porcelain classes, from ultra-low-fusing zirconia porcelains to high-fusing denture teeth.

Let KINTEK be your partner in quality.

Contact our dental equipment experts today to discuss how our solutions can enhance the durability and aesthetics of your ceramic restorations.

Visual Guide

Related Products

- Graphite Vacuum Furnace Negative Material Graphitization Furnace

- 1200℃ Muffle Furnace Oven for Laboratory

- Horizontal High Temperature Graphite Vacuum Graphitization Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Large Vertical Graphite Vacuum Graphitization Furnace

People Also Ask

- Is ceramic the same as porcelain teeth? A Guide to Choosing the Right Dental Material

- What is the difference between porcelain and ceramic restoration? Choose the Right Material for Your Smile

- Can ceramic crowns be repaired? A Dentist's Guide to Assessing the Damage

- What does sintering do to zirconia? Unlock Its Full Strength and Aesthetic Potential

- What is ceramic dental restoration? A Guide to Modern, Aesthetic, and Durable Tooth Repair

- What is a ceramic dental furnace? A Precision Tool for Durable, Aesthetic Restorations

- Why are porcelain fired under vacuum? To Eliminate Porosity for Superior Strength & Translucency

- Why is kaolin used for crown teeth? The Key Ingredient for Shaping Strong, Natural-Looking Porcelain