At its core, a porcelain furnace is a highly specialized, programmable oven used in dental laboratories. Its primary function is to fire dental ceramics, transforming layers of porcelain powder into a strong, dense, and aesthetically pleasing final restoration, such as a crown, bridge, or veneer.

A porcelain furnace does more than simply heat; it is a precision instrument that meticulously controls temperature, time, and atmosphere to initiate a chemical and physical transformation, fusing ceramic particles into a durable, lifelike dental prosthetic.

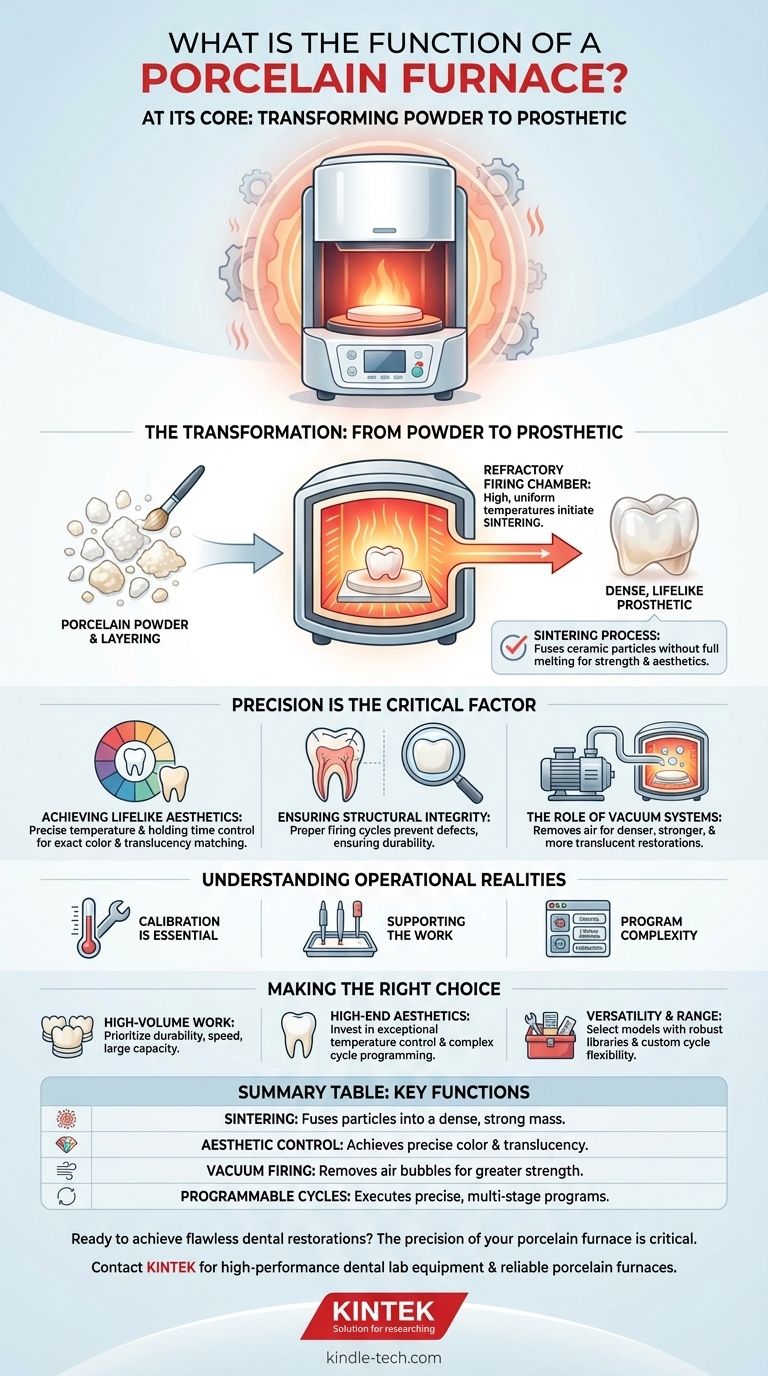

The Transformation: From Powder to Prosthetic

The fundamental purpose of the furnace is to facilitate a process called sintering. This is the critical step that gives a dental restoration its final strength and appearance.

The Refractory Firing Chamber

The heart of the furnace is its refractory firing chamber, also known as a muffle. This chamber is designed to withstand and evenly distribute extremely high temperatures, ensuring the entire restoration is heated uniformly.

The Sintering Process

When a porcelain restoration is "fired," the individual ceramic particles are heated until their surfaces begin to fuse together, without the material fully melting. This process eliminates voids, compacts the material, and creates a single, solid mass.

Building Up the Restoration

Before firing, a dental technician meticulously builds up the restoration in layers using a porcelain slurry. It is then placed on specialized supports like firing pads, pins, or mesh trays inside the chamber to ensure it holds its shape during the intense heating cycle.

Why Precision is the Most Critical Factor

A porcelain furnace is defined by its ability to execute a firing cycle with absolute precision. Even minor deviations can compromise the entire restoration, wasting significant time and materials.

Achieving Lifelike Aesthetics

The final shade, translucency, and surface texture of a porcelain restoration are directly dictated by the firing process. The furnace’s control system must manage the rate of temperature increase and the exact holding temperature to achieve the precise color presentation required to match a patient's natural teeth.

Ensuring Structural Integrity

An improper firing cycle can introduce internal stresses, porosity, or micro-cracks into the ceramic. A precise, well-controlled process ensures the restoration is dense, strong, and durable enough to withstand the forces of chewing for years.

The Role of Vacuum Systems

Many modern furnaces incorporate a vacuum pump. By removing air from the firing chamber during the heating cycle, the furnace can eliminate air bubbles trapped within the porcelain layers. This results in a much denser, stronger, and more translucent final product.

Understanding the Operational Realities

While modern furnaces are highly automated, achieving perfect results requires understanding their components and potential failure points. The quality of the output is entirely dependent on the quality of the input and the condition of the machine.

The Importance of Calibration

The single most common point of failure is improper temperature calibration. If the furnace's thermocouple is not reading the temperature accurately, every firing program will be incorrect. Regular calibration is essential for consistent and predictable results.

Supporting the Work

The choice of firing tray or pins is not trivial. The supports must hold the delicate restoration without causing it to warp or stick as the porcelain sinters and shrinks slightly. Using the wrong support can easily distort the final piece.

Program Complexity

Different ceramic systems (e.g., zirconia, lithium disilicate, feldspathic) require vastly different firing parameters. A furnace must have a flexible and reliable control system capable of storing and executing these complex, multi-stage programs flawlessly.

Making the Right Choice for Your Goal

The selection and use of a porcelain furnace should be directly aligned with the specific outcomes a dental laboratory needs to achieve.

- If your primary focus is high-volume crown and bridge work: Prioritize a furnace known for its durability, fast firing cycles, and a large-capacity muffle.

- If your primary focus is high-end anterior aesthetics: Invest in a furnace with exceptionally precise temperature control and highly programmable cycles to master complex, multi-layered ceramic buildups.

- If your primary focus is versatility and a range of materials: Select a model with a robust library of pre-set programs and the flexibility to easily create and store custom cycles for new materials.

Ultimately, the porcelain furnace is the final crucible where a technician's skill and artistry are transformed into a functional and permanent restoration.

Summary Table:

| Key Function | Description |

|---|---|

| Sintering | Fuses ceramic particles into a dense, strong mass without full melting. |

| Aesthetic Control | Achieves precise color and translucency to match natural teeth. |

| Vacuum Firing | Removes air bubbles for greater strength and density. |

| Programmable Cycles | Executes precise, multi-stage firing programs for different materials. |

Ready to achieve flawless dental restorations? The precision of your porcelain furnace is critical to your lab's success. KINTEK specializes in high-performance dental lab equipment, including reliable porcelain furnaces designed for durability, precise temperature control, and versatile material support. Let us help you enhance your aesthetic outcomes and workflow efficiency. Contact our experts today to find the perfect furnace for your laboratory's needs!

Visual Guide

Related Products

- Vacuum Dental Porcelain Sintering Furnace

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- How does precision temperature control impact TiAl alloy sintering? Master Microstructure Development

- What is the melting point of tungsten in a vacuum? The Real Limit is Sublimation, Not Melting

- What is the difference between VAR and VIM? Legacy Vimscript Variables vs. Modern Neovim API

- What is the advantage of firing porcelain in a vacuum? Achieve Denser, Stronger, and More Aesthetic Dental Restorations

- Why are porcelain fired under vacuum? To Eliminate Porosity for Superior Strength & Translucency