The future of pyrolysis oil is promising but complex, tied directly to its role in the emerging circular economy and global decarbonization efforts. Its growth hinges on advancing the technology to overcome key economic and chemical hurdles, allowing it to serve not as a simple crude oil replacement, but as a valuable component for producing renewable fuels and chemicals from waste materials.

While often discussed as a future fuel, the true potential of pyrolysis oil lies in its ability to convert low-value waste streams—like agricultural residue, forestry waste, and end-of-life plastics—into a refinable, valuable commodity, closing the loop on a circular economy.

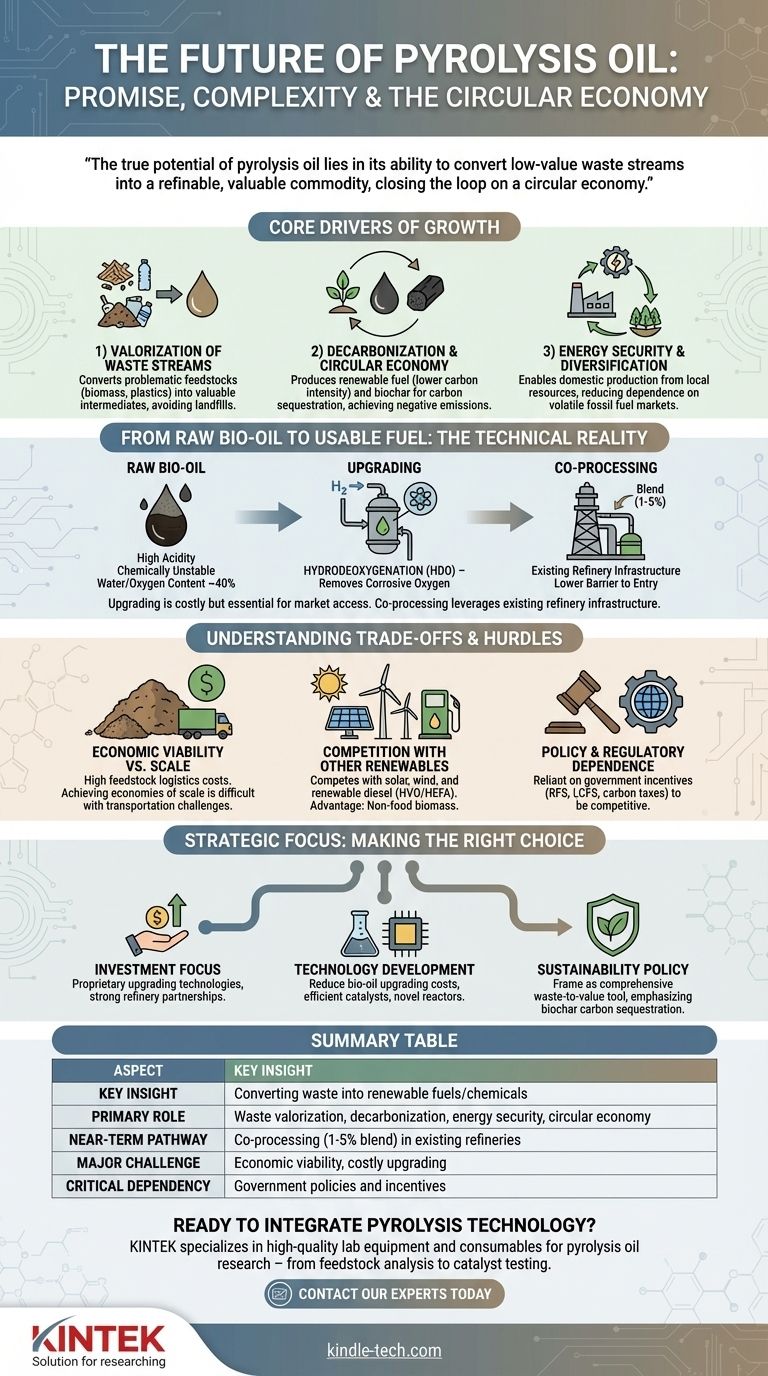

The Core Drivers of Pyrolysis Oil's Growth

The interest in pyrolysis oil isn't based on a single application, but on its unique position at the intersection of waste management, energy production, and climate mitigation. Several key factors are accelerating its development.

Valorization of Waste Streams

Pyrolysis offers a powerful chemical recycling pathway. It can take abundant, low-value, or problematic feedstocks—such as wood chips, corn stover, or mixed plastics that are difficult to mechanically recycle—and convert them into a transportable liquid intermediate.

This process, known as valorization, creates economic value from materials that would otherwise be landfilled, incinerated, or left to decompose.

Decarbonization and the Circular Economy

When derived from biomass, pyrolysis oil is considered a renewable fuel that can lower the carbon intensity of transportation and chemical manufacturing. The process also produces a solid co-product called biochar, a stable form of carbon that can be used to enrich soil and sequester carbon for centuries.

This dual output of a renewable liquid and a carbon-capturing solid makes pyrolysis a compelling technology for achieving negative emission goals.

Energy Security and Diversification

Pyrolysis allows for the domestic production of energy feedstocks from local resources. This reduces a nation's dependence on volatile global fossil fuel markets and enhances energy security.

By creating a distributed network of smaller pyrolysis plants located near biomass sources, regions can create resilient, localized energy ecosystems.

From Raw Bio-oil to Usable Fuel: The Technical Reality

Raw pyrolysis oil, often called bio-oil, is not a "drop-in" fuel that can be immediately used in engines or conventional refineries. Understanding its limitations is key to understanding its future.

The Challenge of Bio-oil Quality

Raw bio-oil is fundamentally different from crude oil. It is highly acidic, chemically unstable, and contains significant amounts of water and oxygen (up to 40% by weight).

These properties make it corrosive to standard pipes and tanks and cause it to degrade over time. Direct use as a fuel is limited to specialized boilers or turbines designed for it.

The Necessity of Upgrading

To be used in a traditional refinery, bio-oil must be "upgraded." This is a chemical stabilization process, most commonly hydrodeoxygenation (HDO), that uses hydrogen and catalysts to remove corrosive oxygen.

Upgrading transforms the unstable bio-oil into a more stable, hydrocarbon-rich oil that resembles conventional crude oil. This step is critical for market access but adds significant cost and complexity.

Co-processing in Existing Refineries

The most viable near-term pathway for pyrolysis oil is co-processing. This involves blending a small percentage (typically 1-5%) of upgraded or, in some cases, raw bio-oil directly into a fluid catalytic cracker (FCC) or hydrotreater unit at an existing petroleum refinery.

This approach leverages billions of dollars of existing infrastructure, dramatically lowering the barrier to entry and allowing refiners to gradually increase their intake of renewable feedstocks.

Understanding the Trade-offs and Hurdles

Despite its potential, the widespread adoption of pyrolysis oil faces significant economic and logistical challenges that will define its future trajectory.

Economic Viability vs. Scale

The economics of pyrolysis are heavily dependent on the cost of its feedstock. Feedstock logistics—the collection, drying, and transportation of bulky biomass to a processing facility—can account for a major portion of the final product's cost.

Achieving economies of scale is difficult. While larger plants are more efficient, they require a massive, consistent supply of feedstock from a wide radius, which drives up transportation costs.

Competition with Other Renewables

Pyrolysis-derived fuels must compete with other renewable alternatives. For electricity, this means solar and wind. For liquid fuels, it competes with ethanol and, more directly, with renewable diesel (HVO/HEFA) made from vegetable oils and fats.

While more expensive today, pyrolysis holds a long-term advantage as it can use non-food, lignocellulosic biomass, avoiding the food-vs-fuel debate.

Policy and Regulatory Dependence

The current pyrolysis industry is highly dependent on government incentives. Policies like the U.S. Renewable Fuel Standard (RFS), California's Low Carbon Fuel Standard (LCFS), and carbon taxes are essential for making pyrolysis oil economically competitive against cheap fossil fuels.

The long-term stability and strength of these policies will be a critical factor in attracting the investment needed to scale the industry.

Making the Right Choice for Your Goal

The future of pyrolysis oil is best viewed not as a single outcome but as a series of targeted opportunities. Your focus will determine how you should interpret its potential.

- If your primary focus is investment: Concentrate on companies with proprietary upgrading technologies or strong strategic partnerships for co-processing with established refineries.

- If your primary focus is technology development: The most critical challenge to solve is reducing the cost of bio-oil upgrading, either through more efficient catalysts or novel reactor designs.

- If your primary focus is sustainability policy: Frame pyrolysis as a comprehensive waste-to-value tool that delivers both renewable energy and durable carbon sequestration through biochar.

Ultimately, the future of pyrolysis oil is secured by its unique ability to bridge the gap between waste management and energy production, making it a cornerstone technology for a truly circular economy.

Summary Table:

| Aspect | Key Insight |

|---|---|

| Primary Role | Converting waste into renewable fuels/chemicals, not a direct crude oil replacement. |

| Key Drivers | Waste valorization, decarbonization, energy security, and circular economy goals. |

| Major Challenge | Economic viability and the need for costly upgrading (e.g., hydrodeoxygenation). |

| Near-term Pathway | Co-processing (1-5% blend) in existing petroleum refineries. |

| Critical Dependency | Government policies and incentives (e.g., RFS, LCFS, carbon taxes). |

Ready to integrate pyrolysis technology into your laboratory research or scale-up plans?

KINTEK specializes in providing the high-quality lab equipment and consumables essential for advancing pyrolysis oil research—from initial feedstock analysis to catalyst testing and process optimization. Our expertise supports the development of sustainable solutions for converting waste into valuable resources.

Contact our experts today to discuss how KINTEK can equip your lab for the future of renewable energy and the circular economy.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Calciner Small Rotary Kiln Rotating Furnace

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What is a disadvantage of biomass energy? The Hidden Environmental and Economic Costs

- What are the different types of pyrolysis machines? Choose the Right System for Your Output

- What is the process of biomass fast pyrolysis? Turn Biomass into Bio-Oil in Seconds

- What are the components of biomass pyrolysis? A Complete Guide to the System, Products, and Process

- How is energy converted into biomass? Harnessing Nature's Solar Power for Renewable Energy