The future of pyrolysis oil is significant and multifaceted, positioning it as a key transitional resource in the shift toward a circular economy. Its primary scope lies not as a simple, direct replacement for crude oil, but as a versatile intermediate feedstock for producing sustainable fuels, high-value chemicals, and other essential materials, provided key technical challenges in upgrading and stabilization are overcome.

While often discussed as a direct fuel, the true future potential of pyrolysis oil lies in its integration into existing industrial infrastructure—like refineries and chemical plants—to create higher-value, renewable products. Its success hinges on solving its inherent chemical instability.

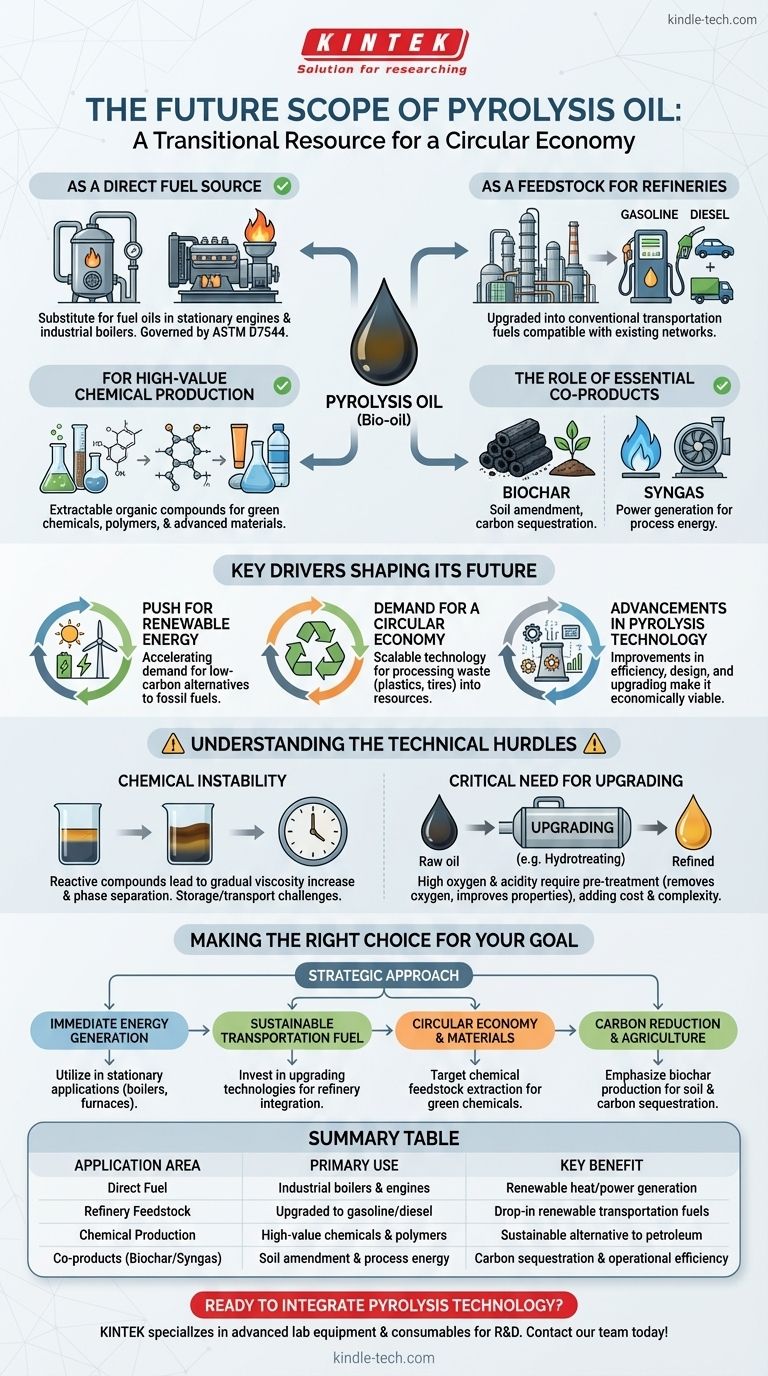

The Expanding Applications of Pyrolysis Products

Pyrolysis is a thermochemical decomposition process that breaks down biomass or waste materials in the absence of oxygen. This process yields not just oil but a suite of valuable products, each with a distinct and growing application area.

As a Direct Fuel Source

Pyrolysis oil, often called bio-oil, can be used as a substitute for conventional fuel oils. Its most immediate application is in stationary engines and industrial boilers for heat and power generation.

This usage is governed by standards like ASTM D7544, which ensures quality and compatibility for these specific applications.

As a Feedstock for Refineries

A more advanced and promising application is upgrading pyrolysis oil within existing refinery infrastructure. Through processes like hydrotreating, it can be converted into conventional hydrocarbon fuels like gasoline and diesel.

This pathway allows for the production of renewable transportation fuels that are compatible with today's vehicles and distribution networks.

For High-Value Chemical Production

Perhaps its most strategic long-term use is as a feedstock for the chemical industry. The oil contains a complex mixture of organic compounds that can be extracted and used to produce renewable chemicals, polymers, and other advanced materials.

This application directly supports the move away from petroleum-based chemical manufacturing, contributing to a more sustainable industrial model.

The Role of Essential Co-Products

The pyrolysis process also creates two other critical outputs: biochar and syngas.

Biochar is a stable, carbon-rich solid that can be used as a powerful soil amendment to improve fertility and as a tool for long-term carbon sequestration.

Syngas, a mixture of hydrogen and carbon monoxide, is a fuel gas that can be used to generate electricity or heat, often to power the pyrolysis process itself.

Key Drivers Shaping Its Future

The momentum behind pyrolysis oil is not based on technology alone. It is being driven by powerful economic and environmental trends that are reshaping global industry.

The Push for Renewable Energy

As nations and corporations commit to reducing their carbon footprint, the demand for renewable alternatives to fossil fuels is accelerating. Pyrolysis offers a method to convert abundant, low-value biomass and waste into valuable energy products.

The Demand for a Circular Economy

Pyrolysis is a cornerstone of the circular economy. It provides a robust and scalable technology for processing waste materials, such as plastics, tires, and agricultural residues, turning potential pollutants into valuable resources.

Advancements in Pyrolysis Technology

Continuous improvements in reactor design, process efficiency, and upgrading techniques are making pyrolysis more economically viable and scalable. These technological advancements are critical for expanding its industrial adoption.

Understanding the Technical Hurdles

To fully grasp the future scope of pyrolysis oil, it is essential to acknowledge the technical challenges that must be addressed. Its widespread adoption is not a simple plug-and-play solution.

The Challenge of Chemical Instability

Pyrolysis oil is not chemically stable like crude oil. It is composed of reactive compounds that can change over time.

This results in a gradual increase in viscosity and potential phase separation, complicating long-term storage and transportation. Heating the oil can cause it to rapidly solidify, creating significant operational challenges.

The Critical Need for Upgrading

Due to its high oxygen content, acidity, and instability, pyrolysis oil generally cannot be used as a "drop-in" fuel in modern engines or refineries without pre-treatment.

It must be upgraded to remove oxygen and improve its properties, a process that adds both cost and complexity to the overall production chain. This step is a primary focus of current research and development.

Making the Right Choice for Your Goal

Understanding the applications and challenges allows for a strategic approach to leveraging pyrolysis technology based on specific objectives.

- If your primary focus is immediate energy generation: Utilize pyrolysis oil in stationary applications like boilers and furnaces, where its properties are manageable under existing standards.

- If your primary focus is sustainable transportation fuel: Invest in or develop upgrading technologies that can integrate pyrolysis oil into existing refinery operations.

- If your primary focus is a circular economy and high-value materials: Target the extraction of chemical feedstocks from the oil to produce green chemicals and bioplastics.

- If your primary focus is carbon reduction and agriculture: Emphasize the production and application of the biochar co-product for soil amendment and carbon sequestration.

Pyrolysis oil stands as a pivotal technology in the transition to a more sustainable and resource-efficient economy.

Summary Table:

| Application Area | Primary Use | Key Benefit |

|---|---|---|

| Direct Fuel | Industrial boilers & engines | Renewable heat/power generation |

| Refinery Feedstock | Upgraded to gasoline/diesel | Drop-in renewable transportation fuels |

| Chemical Production | High-value chemicals & polymers | Sustainable alternative to petroleum |

| Co-products (Biochar/Syngas) | Soil amendment & process energy | Carbon sequestration & operational efficiency |

Ready to integrate pyrolysis technology into your operations? KINTEK specializes in advanced lab equipment and consumables for pyrolysis research and development. Whether you're developing new upgrading catalysts, analyzing bio-oil composition, or scaling your process, our precision tools and expert support can help you overcome technical challenges and accelerate your path to sustainable innovation. Contact our team today to explore how our solutions can enhance your pyrolysis projects and contribute to a circular economy.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Calciner Small Rotary Kiln Rotating Furnace

- Custom PTFE Teflon Parts Manufacturer PTFE Beaker and Lids

- Custom PTFE Teflon Parts Manufacturer for PTFE Mesh F4 Sieve

People Also Ask

- What are the conditions for biomass pyrolysis? Optimize Temperature, Heating Rate & Time

- What are the reactions involved in pyrolysis of biomass? Unlock the Chemistry for Tailored Bio-Products

- What are the products of pyrolysis of biomass? Unlock Bio-Char, Bio-Oil, and Syngas

- What are the different types of pyrolysis machines? Choose the Right System for Your Output

- Is pyrolysis viable? A Guide to Economic, Technological, and Environmental Success