In principle, a "perfect" vacuum is impossible to achieve. A perfect vacuum would be a volume of space with zero particles and zero energy, but the laws of physics prevent this. The highest quality vacuums created in laboratories, known as Extreme High Vacuum (XHV), reach pressures as low as 10⁻¹² Pascals. This is trillions of times lower than atmospheric pressure and even emptier than most of outer space.

The pursuit of a perfect vacuum is not a technological challenge but a battle against the fundamental laws of nature. Even in the most isolated, cryogenically cooled chamber, the container walls, thermal energy, and quantum fluctuations will always introduce particles and pressure.

Defining the "Quality" of a Vacuum

To understand the limits of vacuum, we must first understand that "vacuum" is not an absolute state of nothingness. It is a spectrum defined by the reduction of gaseous pressure in a given volume.

From Air Pressure to Near-Nothingness

The baseline we experience is atmospheric pressure, which is approximately 100,000 Pascals (Pa) at sea level.

Creating a vacuum is the process of using pumps to remove air and other gas molecules from a sealed container, thereby lowering the internal pressure relative to the atmosphere outside.

The Units of Measurement

Pressure in vacuum systems is most commonly measured in Pascals (Pa) or Torr. One atmosphere is about 100,000 Pa or 760 Torr. Lower numbers indicate fewer gas molecules and a higher quality vacuum.

The Vacuum Spectrum

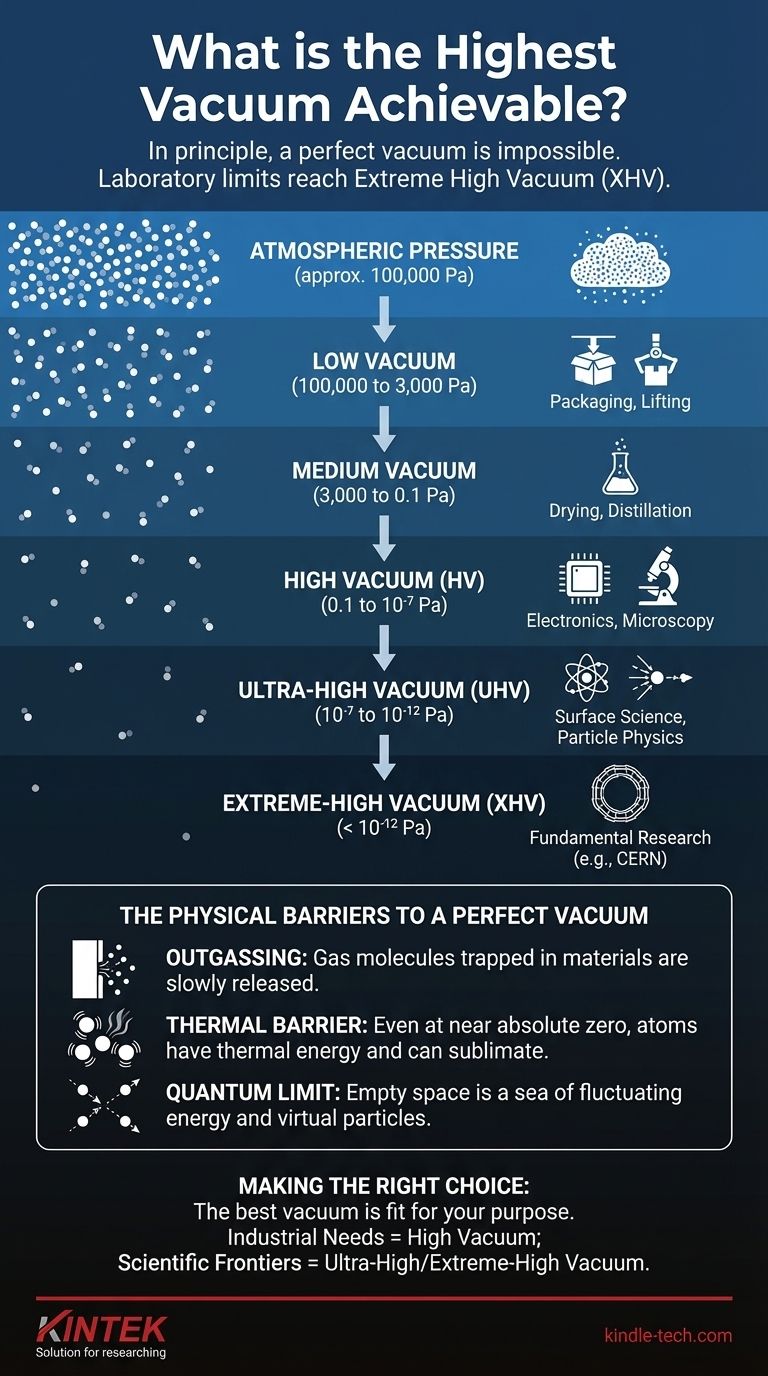

Engineers and scientists classify vacuum into several distinct ranges, each with different physical properties and applications.

- Low Vacuum (100,000 to 3,000 Pa): Used for mechanical tasks like vacuum gripping and packaging.

- Medium Vacuum (3,000 to 0.1 Pa): Common in processes like vacuum drying and distillation.

- High Vacuum (HV) (0.1 to 10⁻⁷ Pa): Required for particle accelerators, electron microscopes, and manufacturing sensitive electronics.

- Ultra-High Vacuum (UHV) (10⁻⁷ to 10⁻¹² Pa): Essential for surface science research and fundamental physics experiments where even a few stray atoms could ruin the results.

- Extreme-High Vacuum (XHV) (< 10⁻¹² Pa): The frontier of vacuum technology, primarily achieved in specialized research facilities like CERN for particle collider experiments.

The Physical Barriers to a Perfect Vacuum

Achieving the highest levels of vacuum is not limited by our ability to build better pumps, but by fundamental physical phenomena that continuously introduce particles into the system.

The Problem of Outgassing

Every material has gas molecules trapped within it or adsorbed on its surface. Under vacuum, these molecules are slowly released back into the chamber in a process called outgassing. The walls of the vacuum chamber itself become the primary source of gas, actively working against the vacuum pumps.

The Thermal Barrier

Even at temperatures near absolute zero (-273.15°C), atoms still possess a tiny amount of thermal energy. This energy can be enough for atoms from the chamber walls to turn into a gas (sublimate), creating a vapor pressure that places a hard limit on the achievable vacuum at a given temperature.

The Quantum Limit

The most fundamental barrier is rooted in quantum mechanics. According to quantum field theory, "empty" space is not truly empty. It is a sea of fluctuating energy from which pairs of virtual particles and anti-particles spontaneously pop into existence and annihilate each other in fractions of a second. This quantum foam ensures that no volume of space can ever have zero energy or zero particles.

Understanding the Trade-offs and Applications

The level of vacuum required is dictated entirely by the goal. Pushing for a higher-quality vacuum than necessary introduces immense cost and complexity.

Industrial Needs: Good Enough is Best

For applications like vacuum furnaces or coating systems, a high vacuum is sufficient. The goal is simply to remove enough reactive particles (like oxygen) to prevent contamination or unwanted chemical reactions. Going further provides no additional benefit and drastically increases cost.

Scientific Frontiers: Purity Above All

In fields like particle physics or surface science, the goal is often to study the behavior of a single particle or a pristine atomic surface. Here, any collision with a stray gas molecule can invalidate the entire experiment. This is why facilities like the Large Hadron Collider at CERN operate under ultra-high vacuum, ensuring particles can travel for kilometers without hitting anything. The cost is immense, but it is a non-negotiable requirement for the science.

Making the Right Choice for Your Goal

The "best" vacuum is the one that is fit for your specific purpose. The question is not how low you can go, but what level of environmental control you actually need.

- If your primary focus is industrial processing: Low to high vacuum is almost always sufficient, cost-effective, and reliable for preventing contamination and enabling physical processes.

- If your primary focus is manufacturing sensitive electronics or optics: High vacuum is necessary to create the pristine, particle-free environments required for thin-film deposition and etching.

- If your primary focus is fundamental physics research: Ultra-high or extreme-high vacuum is the only option to isolate phenomena at the atomic and subatomic levels.

Ultimately, a vacuum is a powerful tool for creating an atomically clean environment, and its "highest" level is defined not by a single number, but by the physical limits of matter and energy itself.

Summary Table:

| Vacuum Level | Pressure Range (Pa) | Primary Applications |

|---|---|---|

| Low Vacuum | 100,000 - 3,000 | Packaging, Lifting |

| Medium Vacuum | 3,000 - 0.1 | Drying, Distillation |

| High Vacuum (HV) | 0.1 - 10⁻⁷ | Electronics, Microscopy |

| Ultra-High Vacuum (UHV) | 10⁻⁷ - 10⁻¹² | Surface Science, Particle Physics |

| Extreme-High Vacuum (XHV) | < 10⁻¹² | Fundamental Research (e.g., CERN) |

Ready to achieve the precise vacuum environment your project demands?

Whether you require reliable high vacuum for industrial processing or ultra-high vacuum for sensitive R&D, KINTEK has the expertise and equipment to meet your needs. Our specialized lab equipment and consumables are designed to deliver the performance and purity essential for your success.

Contact our vacuum experts today to discuss your specific application and discover how KINTEK can provide the perfect solution for your laboratory.

Visual Guide

Related Products

- Circulating Water Vacuum Pump for Laboratory and Industrial Use

- Laboratory Vertical Water Circulating Vacuum Pump for Lab Use

- Oil Free Diaphragm Vacuum Pump for Laboratory and Industrial Use

- Laboratory Benchtop Water Circulating Vacuum Pump for Lab Use

- Laboratory Rotary Vane Vacuum Pump for Lab Use

People Also Ask

- What are the core capabilities of a fast pyrolysis furnace in producing lignin-derived bio-oil? Maximize Your Yield

- What are the benefits of using HIP equipment for high-entropy alloys? Achieve Near-Theoretical Density & Durability

- What is sintering and melting in additive manufacturing? Choose the Right Process for Your Part's Strength and Density

- Why is a high vacuum preferred over argon for sintering VC/Cu composites? Achieve Superior Wetting and Bond Strength

- What metals Cannot be brazed? Understanding the Challenges of Low Melting Points and Reactive Oxides

- What is the process of quenching? A Guide to Controlled Metal Hardening

- What is the vacuum heat treatment cycle? Achieve Superior Material Purity and Precision

- What is var stainless? Discover the Power of Vanadium Stainless Steel for Superior Wear Resistance