Controlling grain growth during the sintering of ceramics is paramount because the final grain size is one of the most powerful levers for dictating a material's mechanical, optical, and electrical properties. Uncontrolled growth leads to a coarse, and often flawed, microstructure that severely compromises performance, particularly strength and toughness. By managing grain size, you are directly engineering the final properties of the ceramic component.

Sintering presents a fundamental conflict: the thermal energy required to fuse particles together and eliminate porosity also drives grains to grow larger. The core challenge is to achieve full densification while simultaneously suppressing grain growth, as unchecked growth can trap pores and degrade properties before the part is even fully dense.

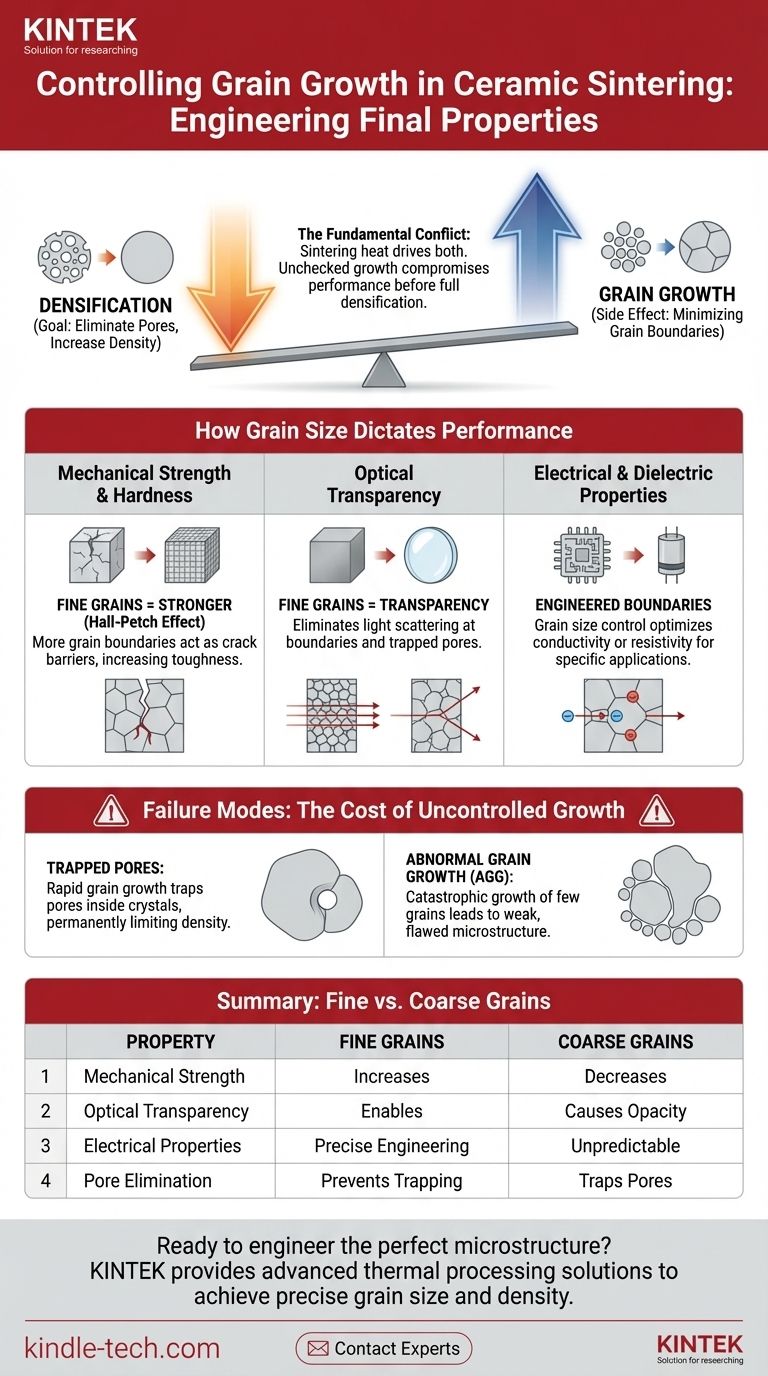

The Fundamental Goal: Densification vs. Grain Growth

To understand the importance of control, you must first understand the two competing mechanisms at the heart of sintering.

What is Sintering?

Sintering is a thermal process that converts a porous powder compact into a dense, solid object. Heat is applied below the material's melting point, activating atomic diffusion that fuses the individual particles together.

The Drive for Densification

The primary goal of sintering is to eliminate the empty spaces (pores) between the initial powder particles. The system is driven to reduce its high surface energy by replacing the solid-vapor interfaces (pore surfaces) with lower-energy solid-solid interfaces (grain boundaries). This process shrinks the part and increases its density.

The Inevitable Side Effect: Grain Growth

Simultaneously, the system also seeks to reduce its energy by minimizing the total area of its grain boundaries. This occurs as larger grains consume smaller, adjacent grains. This process, known as grain growth or coarsening, is driven by the same thermal energy that enables densification.

How Grain Size Dictates Ceramic Performance

The final microstructure, and specifically the average grain size, has a direct and predictable impact on the material's most critical properties.

Mechanical Strength and Hardness

This is the most critical relationship for structural ceramics. The strength of a ceramic is governed by the Hall-Petch effect, which states that strength and hardness increase as grain size decreases.

Smaller grains create more grain boundaries. These boundaries act as barriers, impeding the movement of dislocations and making it much more difficult for cracks to propagate through the material. A fine-grained ceramic forces a crack to change direction constantly, dissipating energy and increasing toughness.

Optical Transparency

For transparent ceramics like YAG laser gain media or sapphire windows, grain boundaries are disastrous. Each boundary acts as a scattering center for light, making the material translucent or opaque.

To achieve transparency, you need to eliminate all scattering sources. This means reaching full density (no pores) and either having no grain boundaries (a single crystal) or having grains so small and uniform that their scattering effect is negligible. Uncontrolled grain growth makes transparency impossible.

Electrical and Dielectric Properties

Grain boundaries can significantly influence electrical behavior. In many oxides, they act as resistive barriers, impeding the flow of ions or electrons and lowering overall conductivity.

Conversely, this effect can be engineered. In certain capacitor materials, dopants are used to create highly resistive grain boundaries and highly conductive grains. This structure (a boundary layer capacitor) results in an extremely high effective dielectric constant. Controlling grain size is key to optimizing this effect.

Understanding the Trade-offs and Failure Modes

The push for densification can easily lead to microstructural failures if grain growth is not managed correctly.

The Problem of Trapped Pores

A catastrophic failure mode occurs when grain boundaries move much faster than pores can be eliminated. A rapidly growing grain can sweep past a pore, trapping it inside the crystal lattice.

Once a pore is trapped within a grain, it is nearly impossible to remove. This permanently limits the final density of the ceramic, creating a weak and flawed component regardless of how long you continue to sinter it.

Abnormal Grain Growth (AGG)

Under certain conditions, a small number of grains can grow catastrophically large at the expense of their neighbors, a phenomenon called Abnormal or Exaggerated Grain Growth (AGG).

This leads to a bimodal and non-uniform microstructure with terrible mechanical properties. The large grains provide easy paths for crack propagation, drastically reducing the strength and reliability of the material.

The Cost of Control

Controlling grain growth often involves trade-offs. Using lower sintering temperatures to slow growth requires significantly longer processing times, increasing energy costs. Using chemical dopants to pin grain boundaries can sometimes affect other desired properties of the material.

Making the Right Choice for Your Application

The ideal sintering strategy depends entirely on the desired outcome for the final component.

- If your primary focus is maximum mechanical strength and hardness: Prioritize achieving the smallest possible, uniform grain size by using grain growth inhibitors and advanced, rapid sintering methods.

- If your primary focus is optical transparency: Your goal is to eliminate all scattering centers, meaning you must prevent pore trapping at all costs, often through high-purity powders and multi-stage sintering cycles.

- If your primary focus is a specific electrical property: You must carefully control both the grain size and the grain boundary chemistry, often through the precise addition of dopants.

- If your primary focus is cost-effective production of a dense part: Optimize a conventional single-stage sintering cycle to reach the target density without inducing abnormal grain growth, accepting a moderate final grain size.

Ultimately, mastering the interplay between densification and grain growth is what transforms a simple powder into a high-performance engineered material.

Summary Table:

| Property | Effect of Fine Grains | Effect of Coarse Grains |

|---|---|---|

| Mechanical Strength | Increases (Hall-Petch Effect) | Decreases significantly |

| Optical Transparency | Enables transparency (reduces scattering) | Causes opacity or translucency |

| Electrical Properties | Allows precise boundary engineering | Leads to unpredictable behavior |

| Pore Elimination | Prevents pore trapping, aids full densification | Traps pores, limits final density |

Ready to engineer the perfect microstructure for your ceramic components?

Controlling grain growth is a delicate balance that requires the right equipment and expertise. At KINTEK, we specialize in providing advanced laboratory equipment and consumables tailored for precise thermal processing and materials research.

Whether you are developing high-strength structural ceramics, transparent optical components, or specialized electronic materials, our solutions can help you achieve the exact grain size and density your application demands.

Contact our experts today to discuss how we can support your sintering process and help you unlock the full potential of your ceramic materials.

Visual Guide

Related Products

- 1800℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is the cooling process of hardening? Master the Quenching Step for Maximum Hardness

- How does furnace temperature precision affect Inconel 718 grain size? Master Microstructural Control

- What are the physical properties of sinter? Optimizing Strength, Reducibility & High-Temperature Performance

- What temperature is aluminum vacuum brazing? Achieve Perfect Joints with Precision Heating

- What is the purpose of using a vacuum drying oven for Na3V2(PO4)3 (NVP) electrodes? Ensure Battery Stability

- How does a sintering furnace work? Achieve Superior Material Strength and Density

- What are the disadvantages of nitriding over carburizing? A Guide to Process Limitations

- How does a high-temperature furnace contribute to the PWHT of 2.25Cr-1Mo steel? Ensure Weld Integrity and Stability