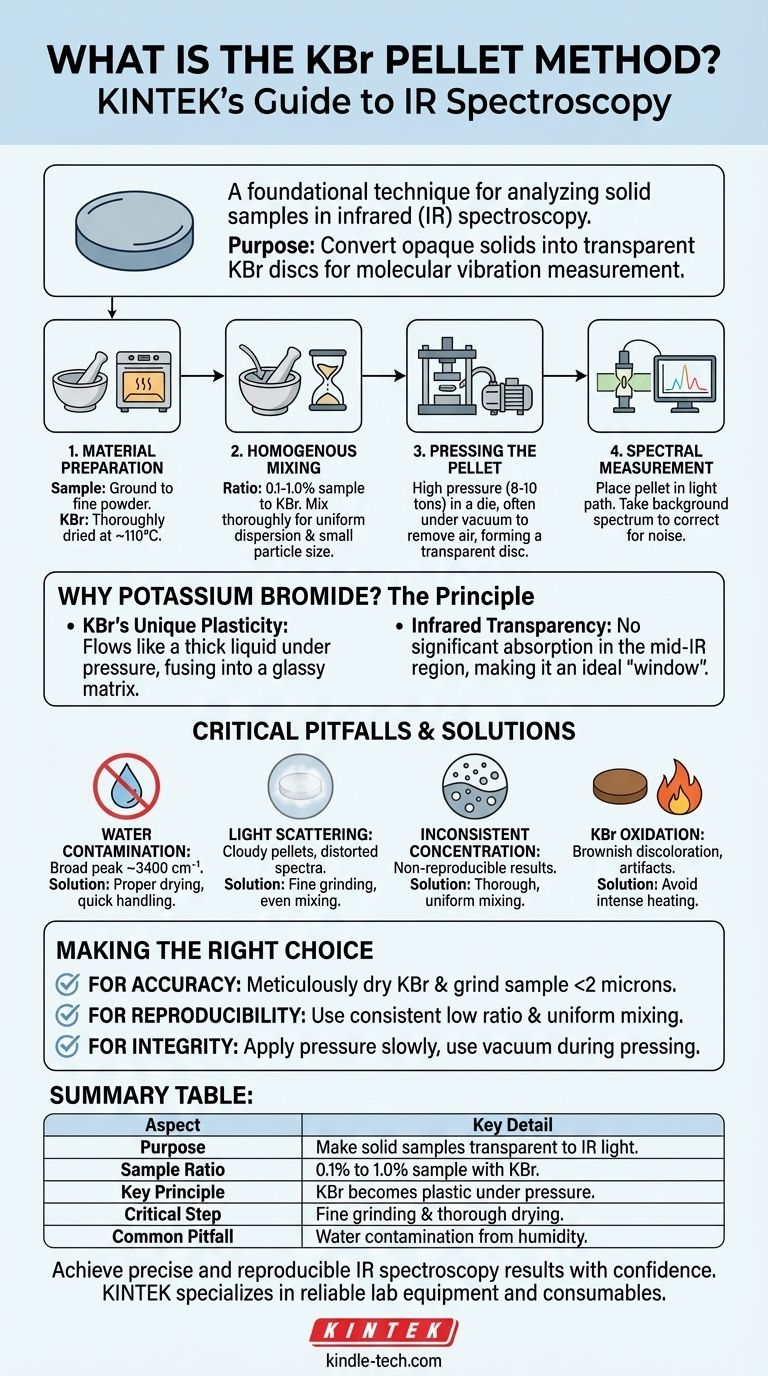

In infrared (IR) spectroscopy, the KBr pellet method is a foundational technique for analyzing solid samples. It involves intimately mixing a small amount of a solid sample (0.1–1.0%) with high-purity, dry potassium bromide (KBr) powder. This mixture is then crushed under immense pressure in a die to form a small, thin, transparent disc or "pellet," which can be directly analyzed in a spectrometer's light path.

The core purpose of the KBr pellet method is to convert an opaque, solid sample into a medium that is transparent to infrared light. By dispersing the sample particles in a non-absorbing KBr matrix, the spectrometer can measure the sample's unique molecular vibrations without interference.

The Principle: Why Potassium Bromide?

The entire method relies on the unique physical properties of alkali halides like KBr. Understanding these properties makes the process intuitive.

KBr's Unique Plasticity

Under high pressure (typically 8-10 tons), KBr powder exhibits plasticity. This means it flows like a very thick liquid, fusing its individual grains together.

When the pressure is released, the KBr solidifies into a single, glassy, semi-transparent sheet, trapping the sample particles within it.

Infrared Transparency

Critically, pure KBr has no significant molecular vibrations—and thus no absorption peaks—in the standard mid-infrared region (4000–400 cm⁻¹).

This makes it an ideal "window" or matrix. The resulting spectrum shows only the absorption peaks from your sample, not the material holding it.

The Step-by-Step Preparation Process

Achieving a high-quality spectrum requires meticulous attention to detail at each stage of pellet preparation.

Step 1: Material Preparation

The first step is to prepare both your sample and the KBr. The sample must be ground into an extremely fine powder.

Simultaneously, the KBr powder, which is highly hygroscopic (readily absorbs water), must be thoroughly dried. This is typically done by heating it at ~110°C for 2-3 hours.

Step 2: Homogenous Mixing

A very small amount of the finely ground sample is mixed with the dry KBr powder. The typical ratio is 0.1% to 1.0% sample to KBr by weight.

This mixture must be ground together to ensure the sample particles are uniformly dispersed and reduced to a size smaller than the wavelength of the IR light to prevent scattering.

Step 3: Pressing the Pellet

The powder mixture is placed into the cavity of a pellet die. The die is assembled and placed in a hydraulic press.

Pressure is applied, often while pulling a vacuum on the die. The vacuum removes trapped air and residual moisture, which helps create a more transparent and durable pellet.

Step 4: Spectral Measurement

Once pressed, the transparent pellet is removed from the die. It is often retained within a stainless steel collar for easy handling.

The pellet is placed in a sample holder in the spectrometer's beam path. A background spectrum, using either a pure KBr pellet or an empty holder, is taken to correct for instrument noise and atmospheric absorption.

Understanding the Critical Pitfalls

The KBr method is powerful but sensitive to procedural errors. These common issues are the primary cause of poor-quality spectra.

The Problem of Water Contamination

Because KBr is so hygroscopic, any exposure to humid air can introduce water into the pellet. Water has a very strong, broad absorption peak in the IR spectrum (~3400 cm⁻¹), which can easily obscure important sample peaks in that region.

Proper drying and quick handling are non-negotiable.

Light Scattering and Cloudy Pellets

If the sample particles are too large or not evenly mixed, the final pellet will appear cloudy or opaque.

This causes light to scatter rather than pass through cleanly, resulting in a distorted spectrum with a sloping baseline and misshapen peaks (an issue known as the Christiansen effect). Fine grinding is the solution.

Inconsistent Concentration

If the sample is not homogeneously mixed into the KBr, different parts of the pellet will have different concentrations. This leads to spectra that are not reproducible and makes quantitative analysis impossible.

KBr Oxidation

When drying KBr, avoid rapid, intense heating. This can cause the potassium bromide (KBr) to oxidize into potassium bromate (KBrO₃), which can cause a brownish discoloration in the pellet and potentially add minor artifacts to the spectrum.

Making the Right Choice for Your Goal

Use these recommendations to ensure your results are reliable and your analysis is accurate.

- If your primary focus is spectral accuracy: Meticulously dry your KBr and grind your sample to a particle size smaller than 2 microns to prevent interfering water peaks and baseline-distorting light scattering.

- If your primary focus is reproducibility: Ensure you use a consistent, low sample-to-KBr ratio (0.1-1.0%) and mix the powders thoroughly in a mortar and pestle to guarantee uniform dispersion.

- If your primary focus is pellet integrity: Apply pressure slowly and always use a vacuum during pressing to remove trapped air, which is the primary cause of pellets that crack, break, or are opaque.

Mastering these details transforms the KBr method from a delicate art into a reliable scientific tool for precise material analysis.

Summary Table:

| Aspect | Key Detail |

|---|---|

| Purpose | To make solid samples transparent to IR light for analysis. |

| Sample Ratio | 0.1% to 1.0% sample mixed with KBr powder. |

| Key Principle | KBr becomes plastic under high pressure, forming a transparent matrix. |

| Critical Step | Fine grinding and thorough drying to avoid water peaks and scattering. |

| Common Pitfall | Water contamination from humid air or insufficient drying. |

Achieve precise and reproducible IR spectroscopy results with confidence. The KBr pellet method is fundamental for accurate material analysis, but its success depends on high-quality equipment and consumables. KINTEK specializes in providing the reliable lab equipment and consumables—including hydraulic presses, pellet dies, and high-purity KBr powder—that your laboratory needs to master this technique.

Let our expertise support your research. Contact our team today to find the perfect solutions for your spectroscopy workflow.

Visual Guide

Related Products

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

- kbr pellet press 2t

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- XRF & KBR steel ring lab Powder Pellet Pressing Mold for FTIR

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

People Also Ask

- What industries use hydraulic press? Powering Manufacturing, Construction, and R&D

- What does a manual press do? Understand the Two Key Types for Your Lab or Industrial Needs

- How is a laboratory hydraulic manual pellet press utilized in the IR spectroscopy of Pennisetum alopecuroides?

- Why is a laboratory hydraulic press essential for MEA fabrication? Ensure Precision in Hydrogen Compressors

- What is the primary role of a laboratory hydraulic press for sulfide electrolytes? Achieve Maximum Sample Density

- How can hydraulic fluid temperature be reduced? Fix the Root Cause of Overheating

- How do you maintain a press machine? A Proactive Guide to Maximize Uptime and Safety

- How does high pressure from a hydraulic press affect LLZO ceramic pellets? Optimizing Density for Peak Performance