In a laboratory setting, heat safety is a foundational discipline focused on preventing burns, fires, and uncontrolled chemical reactions. It is a system of awareness and procedure that requires understanding your specific heat source, knowing how your materials will react, and using the correct protective equipment and handling techniques at all times.

The safe use of heat in a lab is not just about avoiding burns. It's about developing a comprehensive awareness of how thermal energy interacts with your equipment, your chemicals, and your environment, and proactively managing those interactions to prevent accidents.

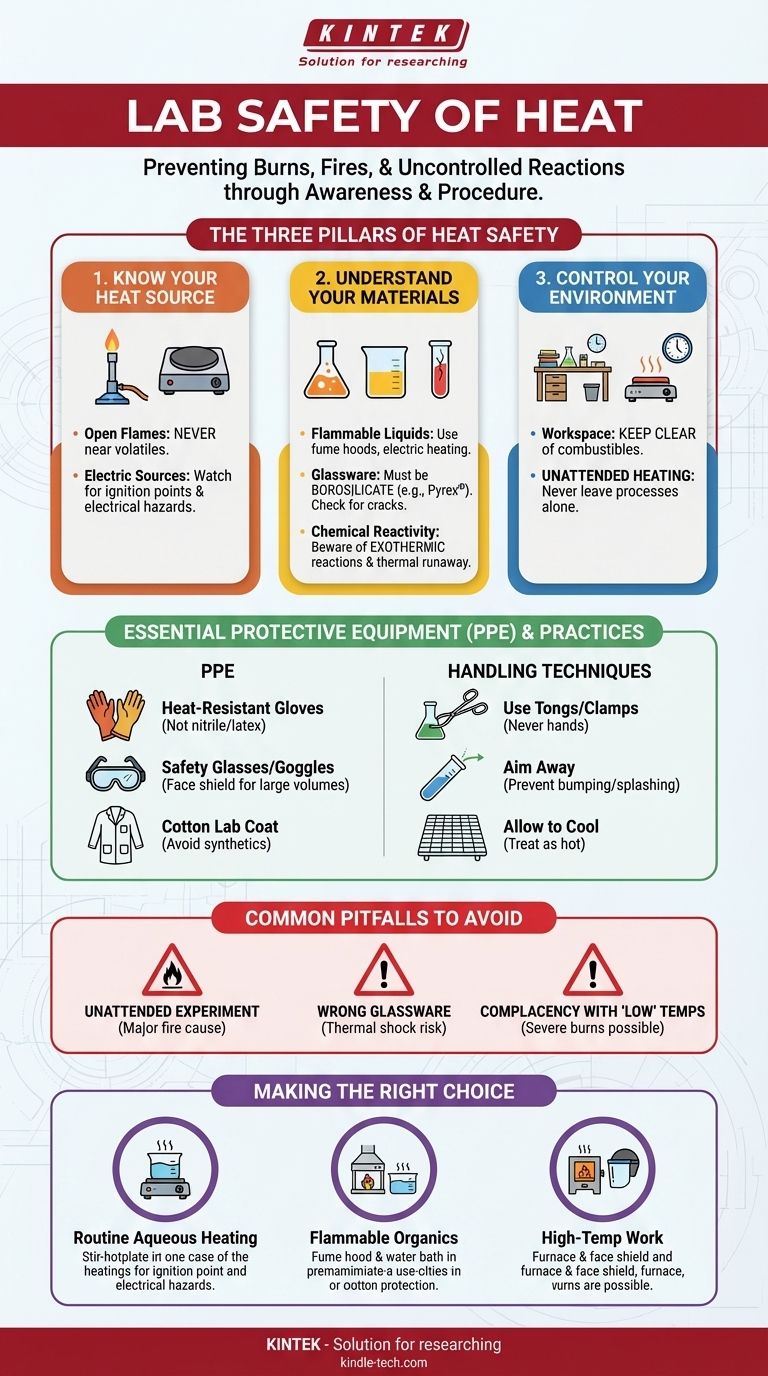

The Three Pillars of Heat Safety

Effective heat safety in the laboratory rests on three core principles. Mastering them provides a framework for assessing risk in any procedure involving heat.

1. Know Your Heat Source

Different sources of heat present distinct hazards.

Open flames, like a Bunsen burner, are an obvious ignition source for flammable materials. They must never be used near volatile organic solvents.

Electric sources, such as hot plates, heating mantles, and ovens, eliminate the risk of an open flame but introduce electrical hazards. They can still act as an ignition source for flammable vapors if their surface temperature exceeds the vapor's autoignition temperature.

2. Understand Your Materials

The substance being heated is a critical part of the safety equation.

Flammable liquids must be handled with extreme care. They should only be heated in a well-ventilated area like a fume hood, using an electric source like a water bath or heating mantle to ensure gentle, even heating.

Glassware must be appropriate for the task. Only use borosilicate glass (e.g., Pyrex®, Kimax®) that is designed to withstand thermal shock. Always inspect it for cracks or chips before use, as these weak points can lead to shattering when heated.

Chemical reactivity must be considered. Some reactions are exothermic, meaning they release their own heat. Uncontrolled heating can trigger a "thermal runaway," a dangerous, accelerating reaction that can lead to an explosion.

3. Control Your Environment

Your immediate workspace is the final line of defense.

Keep the area around any heating apparatus completely clear of unnecessary chemicals, papers, and other combustible materials.

Never leave a heating process unattended. A failure in a cooling system, a faulty stirrer, or an unexpected reaction can escalate into a serious incident very quickly.

Essential Protective Equipment and Practices

Beyond principles, specific tools and techniques are non-negotiable for safe work.

Personal Protective Equipment (PPE)

Your standard lab coat, gloves, and goggles are the starting point, but heat requires specific considerations.

Wear heat-resistant gloves when handling hot objects. Be aware that standard nitrile or latex exam gloves offer no protection from heat and can melt to your skin.

Safety glasses or goggles are mandatory to protect against splashes of hot liquid. A full face shield provides an even higher level of protection when working with larger volumes.

Ensure your lab coat is made of a material like cotton, which will char, rather than a synthetic like polyester, which will melt in the presence of flame.

Proper Handling Techniques

Always use tongs, clamps, or crucible holders to move hot glassware and equipment. Never use your hands, even if you are wearing gloves.

When heating a substance in a test tube or flask, always aim the opening away from yourself and anyone else in the lab. This prevents injury in case the contents "bump" or splash out.

Assume all glassware and equipment remains hot for a significant time after the heat source is removed. Allow items to cool in a designated, out-of-the-way spot before handling them.

Common Pitfalls to Avoid

Most heat-related lab accidents are caused by a few common, preventable mistakes.

The "Unattended" Experiment

This is the single most common cause of lab fires. Even seemingly stable processes can fail. A cooling water line can pop off, a magnetic stirrer can stop working, or a controller can malfunction, leading to overheating and ignition.

Using the Wrong Glassware

Heating non-borosilicate glass is a recipe for disaster. It cannot handle the rapid temperature change (thermal shock) and is likely to shatter, spilling hot, potentially hazardous contents.

Complacency with "Low" Temperatures

A hot plate set to 100°C (212°F) will not glow red, but it can cause a severe burn instantly. Treat all heating devices as if they are at maximum temperature until you have verified they are cool to the touch.

Making the Right Choice for Your Goal

Your specific procedure dictates the necessary safety precautions.

- If your primary focus is routine heating of aqueous solutions: Prioritize using a stir-hotplate for its precise control and ensure all glassware is rated for thermal stress.

- If your primary focus is working with flammable organic solvents: Eliminate all open flames and perform the work in a properly ventilated fume hood, using a water bath or heating mantle as your source.

- If your primary focus is high-temperature digestion or furnace work: Utilize specialized PPE like insulated gloves and a face shield, establish a clear exclusion zone around the equipment, and never work alone.

Ultimately, a disciplined and mindful approach transforms heat from a potential hazard into one of your most powerful laboratory tools.

Summary Table:

| Heat Safety Principle | Key Considerations |

|---|---|

| Know Your Heat Source | Open flames vs. electric sources; ignition risks; electrical hazards. |

| Understand Your Materials | Flammable liquids; proper glassware (borosilicate); chemical reactivity. |

| Control Your Environment | Keep area clear; never leave processes unattended; use fume hoods. |

| Essential PPE | Heat-resistant gloves; safety goggles/face shield; cotton lab coat. |

| Common Pitfalls | Unattended experiments; wrong glassware; complacency with low temperatures. |

Ensure your lab operates safely and efficiently with the right equipment.

KINTEK specializes in providing reliable, high-performance lab equipment and consumables designed with safety in mind. From thermal-rated borosilicate glassware and controlled heat sources like hot plates and heating mantles to essential personal protective equipment, we supply the tools you need to manage thermal hazards effectively.

Contact us today to discuss your laboratory's specific needs. Our experts are ready to help you select the safest and most effective solutions for your heating applications.

Get in touch with our safety specialists now!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is a thick film circuit? A Durable, High-Power Hybrid Electronics Solution

- What are the factors that affect sample size? Optimize Your Study's Power and Precision

- What is the flow rate of a filter press? Mastering the Dynamic Filtration Cycle

- Which technique could be utilized for IR imaging of biological samples? Master FTIR Microspectroscopy for Chemical Mapping

- What are the two types of hot air ovens? Choose the Right Air Circulation for Your Lab

- What is the difference between fusion and sintering? Master Material Joining Methods

- What is the temperature of sputtering plasma in magnetron? Unlocking the Key to Low-Temperature Thin Film Deposition

- What is the demand for synthetic diamonds? Rising Popularity for Ethical & Affordable Gems