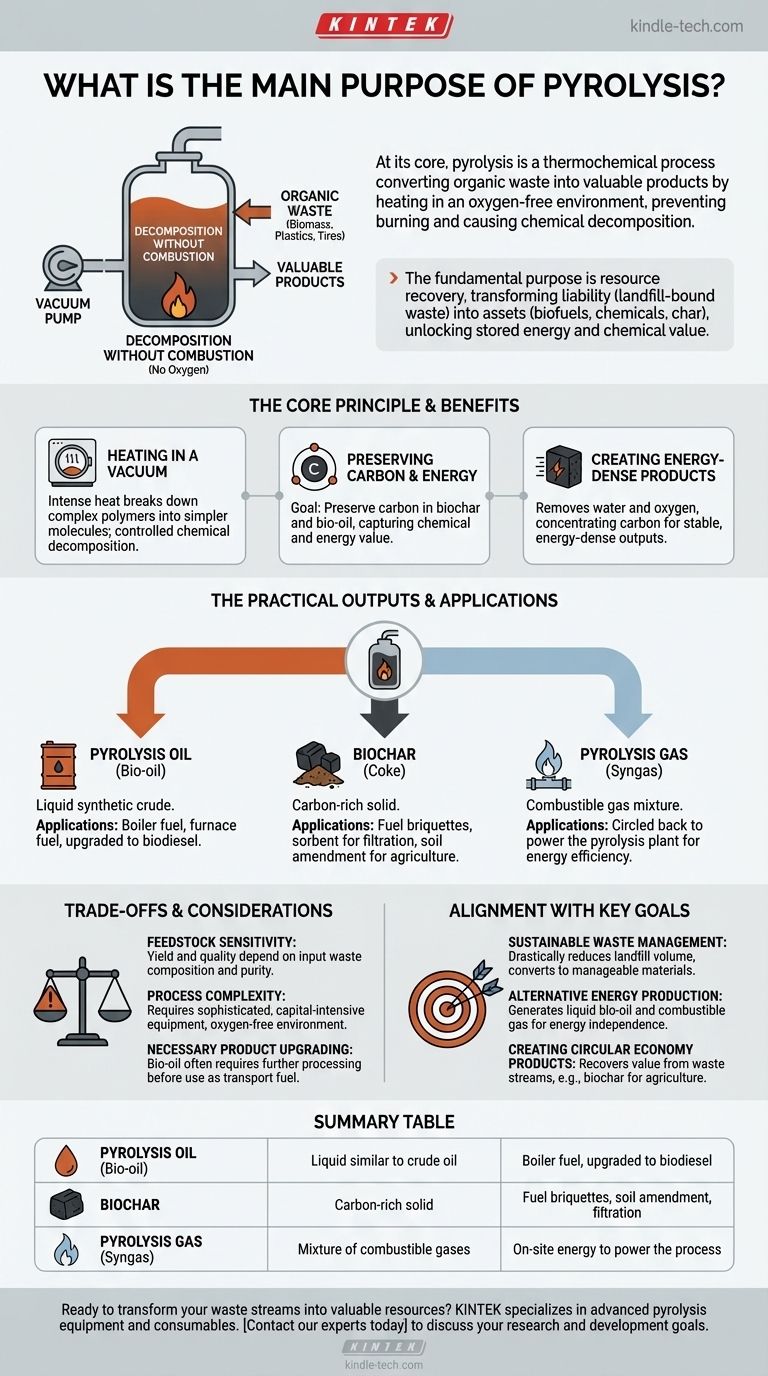

At its core, pyrolysis is a thermochemical process designed to convert organic waste materials, like biomass, plastics, or tires, into valuable products. It achieves this by heating the material to high temperatures in an environment completely devoid of oxygen, preventing it from simply burning and instead causing it to chemically decompose into useful liquids, gases, and solids.

The fundamental purpose of pyrolysis is not merely waste disposal; it is a resource recovery technology. It aims to unlock the stored energy and chemical value within organic materials, transforming a liability (landfill-bound waste) into assets (biofuels, chemicals, and char).

The Core Principle: Decomposition Without Combustion

The distinction between pyrolysis and simple burning (incineration) is critical. By removing oxygen from the equation, pyrolysis changes the fundamental chemical outcome.

Heating in a Vacuum

Instead of combusting, the intense heat breaks down the complex polymers that make up organic matter into simpler, smaller molecules. This process is a controlled chemical decomposition, not a chaotic burn.

Preserving Carbon and Energy

The primary goal of combustion is to release energy as heat by converting carbon into carbon dioxide. Pyrolysis, however, seeks to preserve as much carbon as possible in the solid (biochar) and liquid (bio-oil) products, effectively capturing its chemical and energy value for future use.

Creating Energy-Dense Products

Many forms of waste, particularly biomass, have high water and oxygen content, which makes them inefficient fuels. Pyrolysis drives off this water and oxygen, concentrating the carbon and creating products that are more stable and energy-dense than the original feedstock.

The Practical Outputs of the Process

The value of pyrolysis comes from its three primary outputs, each with distinct applications that turn waste into a resource.

Pyrolysis Oil (Bio-oil)

This is a liquid product that can be seen as a form of synthetic crude oil. While it often requires further refining, it can be used as an alternative fuel for boilers and furnaces or upgraded into higher-grade fuels like biodiesel.

Biochar (Coke)

This stable, carbon-rich solid is similar to charcoal. It has a wide range of uses, from being pressed into briquettes for energy to being used as a powerful sorbent for filtration or as a valuable agricultural soil amendment that improves water retention and nutrient levels.

Pyrolysis Gas (Syngas)

This non-condensable gas is a mixture of hydrogen, carbon monoxide, and methane. While it can be collected and used for other purposes, its most common application is to be circled back to power the pyrolysis plant itself, making the entire process more energy-efficient and self-sustaining.

Understanding the Trade-offs and Considerations

While powerful, pyrolysis is not a universal solution. Understanding its limitations is key to applying it effectively.

Feedstock Sensitivity

The process is not a one-size-fits-all solution. The specific composition, moisture content, and purity of the input waste (the feedstock) have a dramatic impact on the yield and quality of the final products.

Process Complexity

Maintaining an oxygen-free, high-temperature environment requires sophisticated and capital-intensive equipment. It is a more complex and controlled industrial process than simple incineration, demanding higher upfront investment and operational oversight.

Necessary Product Upgrading

The raw outputs, particularly bio-oil, are not always "drop-in" replacements for conventional products. Bio-oil is often acidic and unstable, requiring additional processing (upgrading) before it can be used as a transport fuel, which adds to the overall cost and complexity.

How Pyrolysis Aligns with Key Goals

The decision to implement pyrolysis technology typically depends on the primary strategic objective.

- If your primary focus is sustainable waste management: Pyrolysis offers a powerful method to drastically reduce the volume of waste sent to landfills while converting it into stable, manageable, and even valuable materials.

- If your primary focus is alternative energy production: The process provides a direct pathway to generate liquid bio-oil and combustible gas from local, often renewable, feedstocks, contributing to energy independence.

- If your primary focus is creating circular economy products: Pyrolysis excels at recovering value from waste streams, particularly through the production of biochar for agriculture or industrial carbon applications.

Ultimately, pyrolysis provides a strategic tool for transitioning from a linear "take-make-dispose" economy to a circular one that recaptures value from our waste streams.

Summary Table:

| Pyrolysis Output | Description | Key Applications |

|---|---|---|

| Pyrolysis Oil (Bio-oil) | Liquid similar to crude oil | Boiler fuel, upgraded to biodiesel |

| Biochar | Carbon-rich solid | Fuel briquettes, soil amendment, filtration |

| Pyrolysis Gas (Syngas) | Mixture of combustible gases | On-site energy to power the pyrolysis process |

Ready to transform your waste streams into valuable resources? KINTEK specializes in advanced pyrolysis equipment and consumables for laboratories and pilot plants. Our solutions help you efficiently convert biomass, plastics, and other organic waste into biofuels, biochar, and syngas—enabling sustainable waste management and energy production. Contact our experts today to discuss how our pyrolysis technology can support your research and development goals.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ Muffle Oven Furnace for Laboratory

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Powerful Plastic Crusher Machine

People Also Ask

- What is the process of biomass fast pyrolysis? Turn Biomass into Bio-Oil in Seconds

- What is a disadvantage of biomass energy? The Hidden Environmental and Economic Costs

- What are the different types of pyrolysis machines? Choose the Right System for Your Output

- How is energy converted into biomass? Harnessing Nature's Solar Power for Renewable Energy

- What are the advantages of pyrolysis technology? Turn Waste into Profit and Reduce Emissions