There is no single maximum curing time for the compression molding process. Curing is not a one-size-fits-all parameter; it is a calculated variable that depends entirely on the material being used, the thickness of the part being molded, and the temperature of the mold. A thin part might cure in under a minute, while a very thick, large component could require several hours.

The core principle to understand is that the goal is not to reach a "maximum" time, but an optimal time. This optimal window ensures the material fully cross-links to achieve its desired physical properties without beginning to degrade from excessive heat exposure.

Why "Maximum Time" is a Misleading Concept

In compression molding, we primarily work with thermosetting plastics or elastomers. The "curing" process is a chemical reaction, often called vulcanization or cross-linking, that permanently sets the material into its final shape.

The Cure Curve

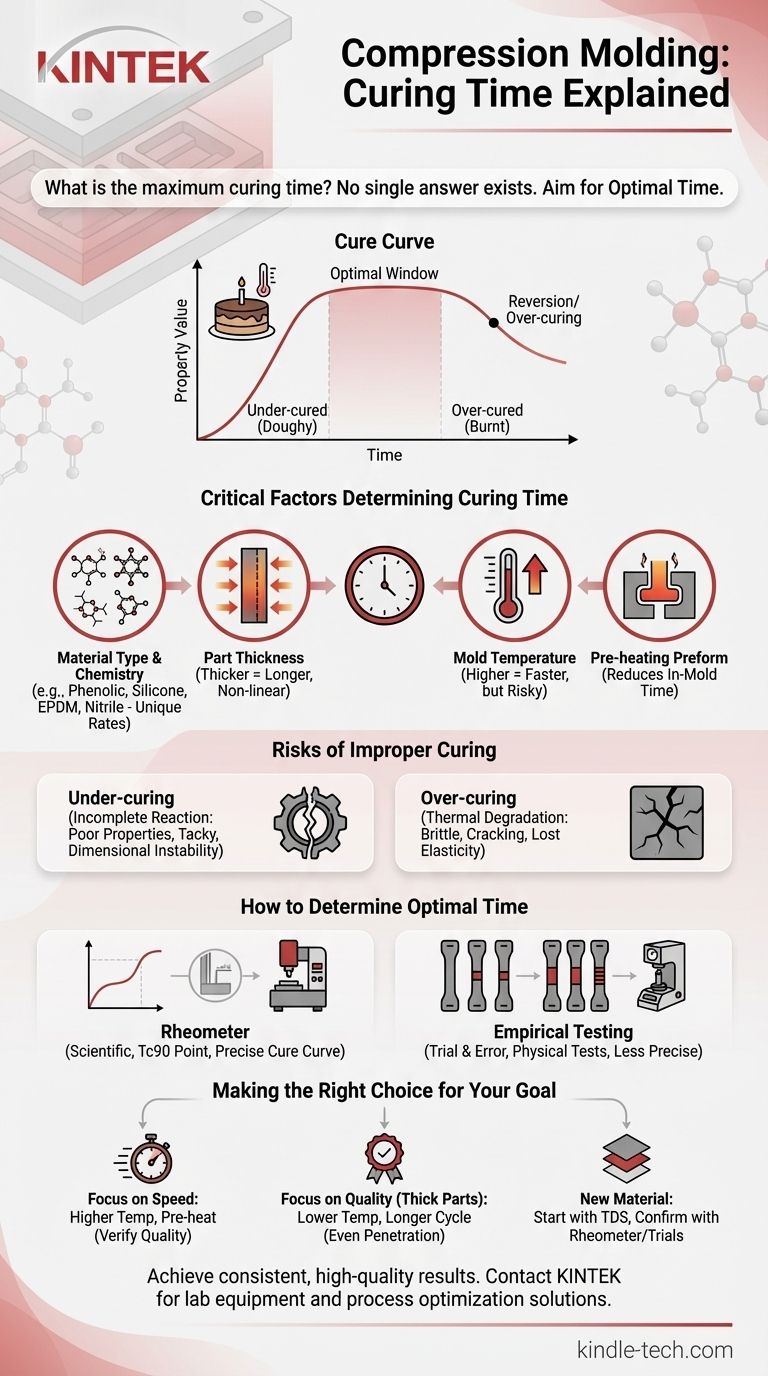

Imagine baking a cake. If you take it out too early, it's undercooked and doughy. If you leave it in too long, it burns. The curing of a thermoset follows a similar principle, scientifically represented by a cure curve.

This curve shows that the material's properties improve rapidly as it cures, hit an optimal plateau, and then begin to decline if left in the heat for too long—a phenomenon known as reversion or over-curing. The "maximum" time you're asking about is actually the point where this degradation begins.

The Critical Factors That Determine Curing Time

To determine the correct curing time for your specific application, you must analyze four key variables.

Factor 1: Material Type and Chemistry

Every material has a unique reaction rate. A phenolic resin has a different curing profile than a silicone rubber, and an EPDM rubber will cure differently from a nitrile rubber. The specific catalyst and accelerator package mixed into the raw material is designed to control this reaction speed.

Factor 2: Part Thickness

This is the most significant factor. Heat must travel from the hot mold surface to the very center of the part. The thicker the part, the longer this thermal transfer takes.

The relationship is not linear. Doubling the thickness of a part can more than double the required cure time to ensure the core is fully cross-linked without over-curing the surface.

Factor 3: Mold Temperature

Higher temperatures accelerate the chemical curing reaction. You can significantly shorten the cure time by increasing the mold temperature.

However, there is a limit. A temperature that is too high can cause the material on the surface to cure too quickly, trapping gas and causing defects, or even scorching the part before the core has a chance to cure.

Factor 4: Pre-heating the Preform

Pre-heating the raw material charge (the "preform") before placing it in the mold can dramatically reduce the required in-mold curing time. Since the material is already close to its reaction temperature, the mold's job is simply to shape it and provide the final energy needed to complete the cross-linking process.

Understanding the Trade-offs: The Risks of Improper Curing

Setting the wrong cure time directly compromises the quality and performance of the final product.

The Problem of Under-curing

If the cycle is too short, the chemical reaction is incomplete. This results in a part with poor mechanical properties, such as low tensile strength, improper hardness, and dimensional instability. The part may also feel tacky or have a lingering chemical smell.

The Problem of Over-curing (Reversion)

If the cycle is too long, the polymer chains begin to break down. This leads to a brittle part that has lost its elasticity and is prone to surface cracking. Over-curing is a form of thermal degradation that permanently damages the material.

How to Determine the Optimal Cure Time

Professionals use two primary methods to find the ideal curing time for a specific part and material combination.

Using a Rheometer

The most scientific and precise method is to use an oscillating disk rheometer. This device tests a small sample of the material at a specific temperature and measures its change in stiffness over time, generating a perfect cure curve.

From this data, engineers identify the Tc90 point—the time it takes to achieve 90% of the full cure. This is the industry-standard benchmark for establishing the optimal in-mold cure time.

Empirical Testing

A more practical but less precise method involves a structured trial-and-error process. Mold several parts, increasing the cure time for each one. Then, perform physical tests (like hardness or compression tests) on each part until you find the time that yields the best properties without signs of over-curing.

Making the Right Choice for Your Goal

Instead of seeking a maximum time, focus on identifying the optimal time for your specific production needs.

- If your primary focus is maximum production speed: Use a higher mold temperature and pre-heat your preforms, but carefully verify part quality to avoid scorching the surface before the core is cured.

- If your primary focus is quality for thick-walled parts: Use a moderately lower mold temperature for a longer cycle time to allow heat to penetrate to the core evenly, ensuring a complete and uniform cure.

- If you are working with a new material or part: Always begin with the manufacturer's technical data sheet (TDS) as a starting point and confirm your optimal time with either rheometer data or controlled molding trials.

Understanding these core principles moves you from guessing at a generic number to being in full control of your manufacturing process and final part quality.

Summary Table:

| Factor | Impact on Curing Time |

|---|---|

| Material Type | Different resins/elastomers have unique chemical reaction rates. |

| Part Thickness | Thicker parts require significantly longer times for heat to penetrate to the core. |

| Mold Temperature | Higher temperatures accelerate curing but risk surface defects if too high. |

| Preform Pre-heating | Reduces in-mold curing time by starting the reaction before molding. |

Achieve consistent, high-quality results in your compression molding process.

Determining the precise, optimal curing time is critical to avoid under-cured or over-cured parts, which directly impacts the performance and durability of your products. KINTEK specializes in lab equipment and consumables, serving the precise needs of laboratories and manufacturers.

Our expertise can help you select the right tools, like rheometers, to accurately characterize your materials and establish perfect curing parameters for your specific application. Contact our experts today to discuss how we can support your material testing and process optimization goals.

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press for Button Battery

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

People Also Ask

- How does a laboratory hydraulic press improve XRF accuracy for catalyst samples? Enhance Precision & Signal Stability

- What role does a laboratory hydraulic press play in the preparation of solid electrolyte pellets? Ensure Data Accuracy

- What is the use of KBr? Master Sample Prep for Accurate IR Spectroscopy

- What is the pressed powder pellet method? A Guide to Accurate FTIR Sample Preparation

- How hot is a hydraulic press? Understanding the Critical Heat in Your Hydraulic System