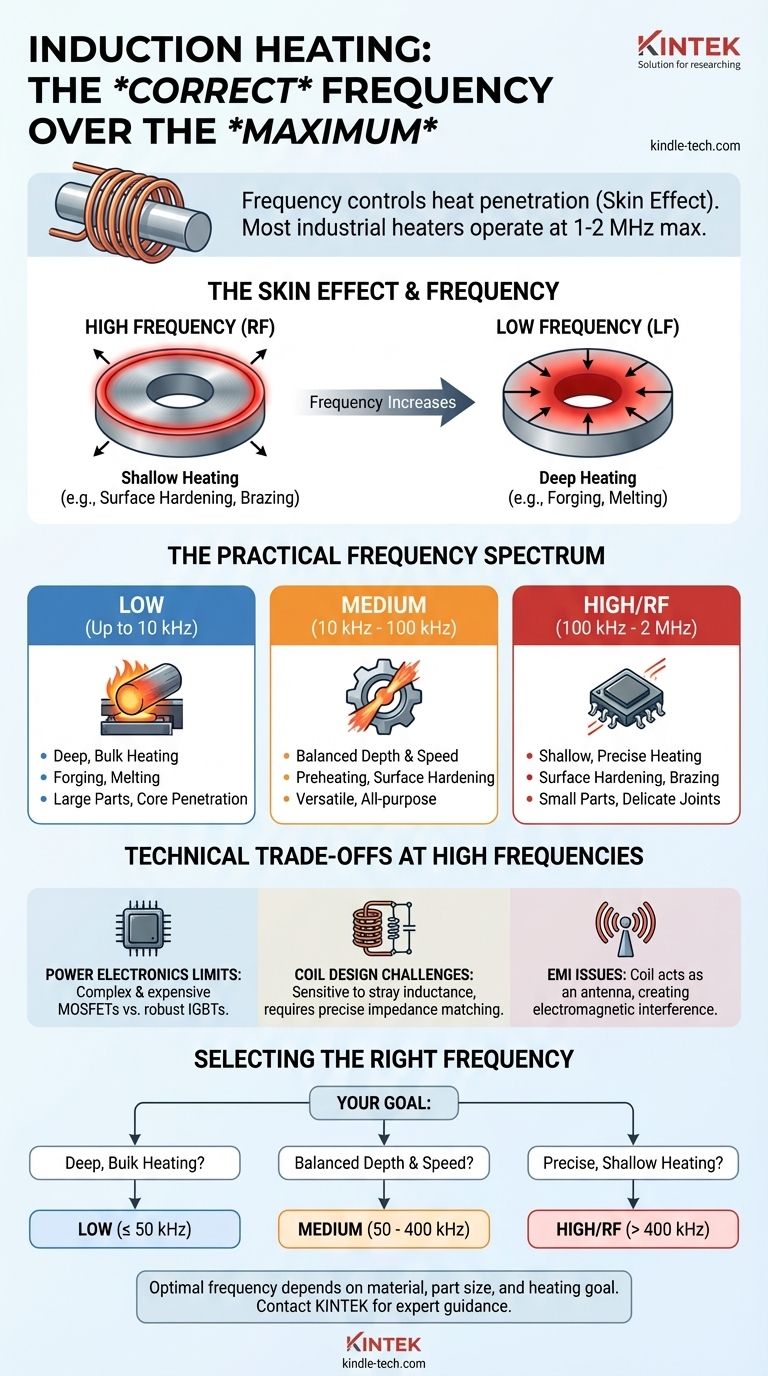

In practice, the maximum frequency for most industrial induction heaters is in the low single-digit megahertz (MHz) range, typically from 1 to 2 MHz. While specialized laboratory or semiconductor processing equipment can operate at higher frequencies, the vast majority of commercial applications for metal heating fall well below this ceiling. The more critical question isn't about the absolute maximum, but why a specific frequency is chosen.

The "maximum" frequency is less important than the correct frequency. In induction heating, frequency is the primary tool used to control the depth of heat penetration into a material—a principle known as the skin effect. Choosing the right frequency is the most critical decision for achieving the desired heating outcome efficiently.

Why Frequency is the Most Critical Parameter

The frequency of the alternating current in the induction coil directly dictates how and where heat is generated in the workpiece. This isn't an arbitrary setting; it's a fundamental physical control.

Introducing the Skin Effect

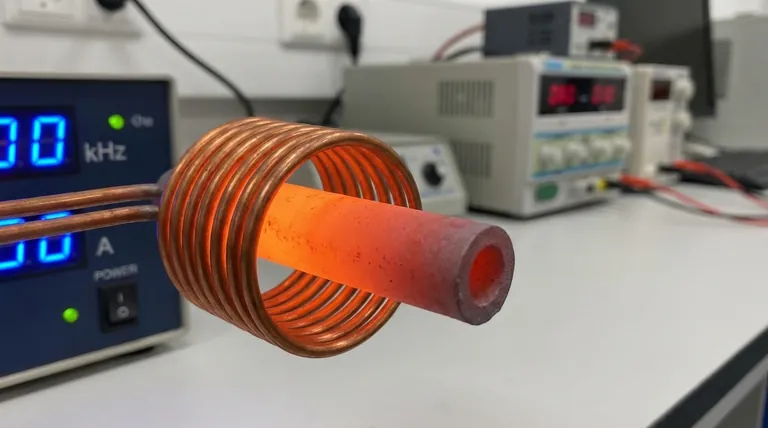

The core principle at play is the skin effect. When an alternating magnetic field induces a current in a conductor, that current tends to concentrate on the surface, or "skin," of the material.

The higher the frequency, the more pronounced this effect becomes, forcing the current to flow in a thinner, more superficial layer. This means high frequency equals shallow heating, while low frequency equals deep heating.

High Frequency for Surface Heating

Frequencies in the radio-frequency (RF) range (100 kHz to several MHz) are used when you only want to heat the surface of a part.

This is ideal for applications like surface hardening a gear tooth, where you need a hard, wear-resistant outer layer while keeping the core of the tooth tough and ductile. Other uses include brazing small, delicate joints or welding thin-walled tubes.

Low Frequency for Deep Heating

Conversely, low to medium frequencies (line frequency up to ~50 kHz) are used for applications requiring deep, uniform heat penetration.

This is necessary for processes like forging, where an entire billet of steel must be heated through to its core before being shaped. It's also used for melting large quantities of metal or through-hardening large shafts.

The Practical Spectrum of Induction Heating

Induction heating systems are generally categorized by their operating frequency range, which corresponds directly to their intended applications.

Low-Frequency (LF) Systems (Up to 10 kHz)

These systems are the workhorses for bulk heating. They use the lowest frequencies to drive heat deep into large parts. Think of heating massive steel billets or melting entire crucibles of metal.

Medium-Frequency (MF) Systems (10 kHz to 100 kHz)

This is a versatile, "all-purpose" range. It provides a good balance between heating depth and speed, making it suitable for preheating parts before welding, surface hardening medium-sized components, and various forging applications.

Radio-Frequency (RF) Systems (100 kHz and Above)

As discussed, this is the domain of precision and surface treatment. RF systems are used for shallow case hardening, brazing, and heating very small parts where the heating zone must be tightly controlled. Most industrial RF systems operate between 100 kHz and 400 kHz, with specialized applications pushing toward 1-2 MHz.

Understanding the Technical Trade-offs

Pushing to extremely high frequencies isn't just unnecessary for most tasks; it's also technically challenging and inefficient for several reasons.

The Limits of Power Electronics

The power supplies that drive induction coils rely on solid-state switches like IGBTs and MOSFETs. IGBTs are robust and can handle immense power but are slower, making them ideal for low- and medium-frequency systems. MOSFETs are much faster and are used in RF systems, but building high-power systems with them is more complex and expensive.

The Challenge of Coil Design

At very high frequencies, the induction coil and the entire circuit become extremely sensitive to stray inductance and capacitance. Achieving efficient power transfer requires precise impedance matching, which becomes progressively more difficult as frequency increases. The coil stops behaving like a simple inductor and starts acting like a complex transmission line.

The Problem of Electromagnetic Interference (EMI)

As the frequency rises into the RF spectrum, the induction coil becomes a more efficient antenna. This means it radiates more electromagnetic energy into the surrounding environment instead of coupling it into the workpiece. This is not only inefficient but also creates significant electromagnetic interference (EMI), which is tightly regulated to prevent disruption to other electronic equipment.

Selecting the Right Frequency for Your Application

The optimal frequency is always dictated by the material, the size of the part, and your specific heating goal. There is no single "best" frequency, only the right tool for the job.

- If your primary focus is deep, bulk heating (e.g., forging, melting): Your application requires low- to medium-frequency systems (typically below 50 kHz) to ensure the heat penetrates to the core of the workpiece.

- If your primary focus is surface hardening or heat treating: Your choice will depend on the required case depth. Medium- to high-frequency systems (50 kHz to 400 kHz) are the standard choice here.

- If your primary focus is precise heating of very small parts or shallow surfaces: You need a high-frequency (RF) system, often operating above 400 kHz, to confine the energy to a very small and shallow area.

Ultimately, selecting the correct frequency is the key to a successful, efficient, and repeatable induction heating process.

Summary Table:

| Frequency Range | Typical Applications | Heating Depth |

|---|---|---|

| Low (Up to 10 kHz) | Forging, Melting | Deep, Bulk Heating |

| Medium (10 kHz - 100 kHz) | Preheating, Surface Hardening | Balanced Depth & Speed |

| High/RF (100 kHz - 2 MHz) | Surface Hardening, Brazing | Shallow, Precise Heating |

Struggling to achieve the right heat penetration in your process? The experts at KINTEK can help. We specialize in laboratory equipment and consumables, providing tailored solutions for your induction heating needs. Whether you require deep bulk heating for forging or precise surface treatment for hardening, our team will guide you to the optimal frequency and equipment. Contact us today to discuss your specific application and enhance your lab's efficiency with the right technology!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Anti-Cracking Press Mold for Lab Use

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Engineering Advanced Fine Ceramics Aluminum Oxide Al2O3 Heat Sink for Insulation

People Also Ask

- What is a silicon carbide heating element? Unlock Extreme Heat for Industrial Processes

- What kind of metal is used in heating elements? A Guide to Materials for Every Temperature & Atmosphere

- What is silicon carbide rod heated to high temperature used as? A Premier Heating Element for Extreme Environments

- What are silicon carbide heating elements used for? Reliable High-Temp Heating for Industrial Processes

- What is SiC elements? The Ultimate High-Temperature Heating Solution