The maximum operating temperature of molybdenum is not a single value; it depends entirely on the operating atmosphere and whether the material is pure, an alloy, or a compound. In a vacuum or inert atmosphere, molybdenum alloys can operate up to 1900°C (3452°F), but in the presence of air, pure molybdenum begins to oxidize rapidly above 600°C (1112°F). For high-temperature use in air, a compound like molybdenum disilicide is required, which can operate up to 1800°C (3272°F).

Understanding the application environment is the single most important factor in determining molybdenum's true temperature limit. Its exceptional high-temperature strength is only accessible when it is protected from oxygen.

The Critical Factor: Operating Environment

The difference between molybdenum succeeding as a high-performance refractory metal and failing catastrophically comes down to one variable: the presence of oxygen.

In an Oxidizing Atmosphere (Air)

Molybdenum has poor resistance to oxidation. While its melting point is very high, it begins to form a volatile oxide (MoO₃) in air at temperatures as low as 400°C (752°F).

This oxidation becomes catastrophic above 600°C (1112°F), leading to rapid material loss and structural failure. Therefore, pure molybdenum cannot be used in air for any sustained high-temperature application.

In a Vacuum or Inert Atmosphere

When protected from oxygen in a vacuum or an inert gas environment (like argon), molybdenum's capabilities are fully realized.

In these conditions, its high melting point of 2623°C (4753°F) allows it to be used for structural components, furnace hardware, and crucibles at extremely high temperatures.

Pure Molybdenum vs. Its Alloys and Compounds

The term "molybdenum" can refer to several distinct materials, each with a different performance profile.

Pure Molybdenum

Pure molybdenum is used for applications like sintering boats or furnace elements in controlled atmospheres. A practical upper limit for these applications is often around 1100°C (2012°F), though it remains solid at much higher temperatures.

Molybdenum Alloys (TZM, Lanthanum Moly)

Alloys are created to enhance specific properties. TZM (Titanium-Zirconium-Molybdenum) is the most common molybdenum alloy.

TZM offers superior strength and a higher recrystallization temperature than pure molybdenum, making it more stable for demanding structural use. These alloys can effectively operate at temperatures up to 1900°C (3452°F) in a vacuum.

Molybdenum Compounds (Molybdenum Disilicide)

To solve the oxidation problem, molybdenum is combined with silicon to create molybdenum disilicide (MoSi₂). This is a ceramic-like material, not a metal.

When heated in air, MoSi₂ forms a protective, self-healing layer of glassy silicon dioxide (SiO₂). This protective layer allows MoSi₂ heating elements to operate continuously in air at temperatures up to 1800°C (3272°F).

Understanding the Trade-offs

Choosing the right molybdenum material requires balancing performance against practical limitations.

The Oxidation Catastrophe

The single most common failure is using pure molybdenum or a molybdenum alloy in an oxidizing environment. The material will sublimate and quickly disappear, leading to complete failure.

Brittleness and Fabrication

Molybdenum is brittle at room temperature, which can make it difficult and expensive to machine and fabricate. This factor must be considered during the design phase of any component.

Cost vs. Performance

Pure molybdenum is the baseline. High-performance alloys like TZM and specialized compounds like MoSi₂ carry a higher cost but are necessary to meet the demands of their specific applications—strength at temperature for TZM, and air-resistance for MoSi₂.

Making the Right Choice for Your Application

Your final material choice must be dictated by the operating environment and performance requirements.

- If your primary focus is high-temperature operation in air: Your only viable option is a molybdenum compound like Molybdenum Disilicide (MoSi₂).

- If your primary focus is structural strength in a vacuum or inert gas: Molybdenum alloys like TZM provide the best performance and stability, with operating limits near 1900°C.

- If your primary focus is a cost-effective solution for a non-oxidizing environment: Pure molybdenum is an excellent choice, provided the temperatures and structural loads are within its practical limits.

Ultimately, matching the form of molybdenum to its intended atmosphere is the key to leveraging its remarkable high-temperature properties.

Summary Table:

| Material / Condition | Maximum Operating Temperature | Key Limiting Factor |

|---|---|---|

| Pure Molybdenum (in Air) | ~600°C (1112°F) | Catastrophic oxidation begins |

| Pure Molybdenum (in Vacuum/Inert Gas) | ~1100°C (2012°F) | Practical limit for components |

| Molybdenum Alloy like TZM (in Vacuum/Inert Gas) | Up to 1900°C (3452°F) | Structural strength at high temperature |

| Molybdenum Disilicide (MoSi₂) (in Air) | Up to 1800°C (3272°F) | Protective oxide layer prevents oxidation |

Unsure which high-temperature material is right for your application?

Choosing the wrong material can lead to rapid failure and costly downtime. The key to leveraging molybdenum's exceptional properties is matching the specific material—pure metal, alloy, or compound—to your exact operating environment.

KINTEK specializes in lab equipment and consumables, providing expert guidance and reliable solutions for your high-temperature challenges. Whether you need components for a vacuum furnace or a system operating in air, we can help you select the right material for peak performance and longevity.

Let our experts guide you to the optimal solution. Contact KINTEK today for a personalized consultation.

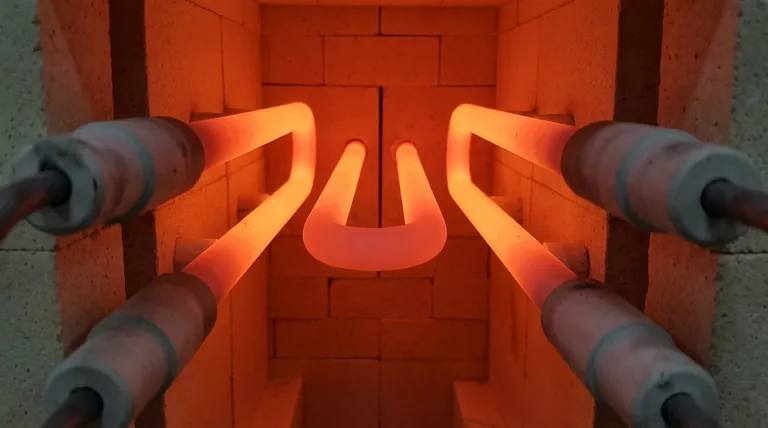

Visual Guide

Related Products

- Molybdenum Disilicide (MoSi2) Thermal Elements Electric Furnace Heating Element

- High-Purity Titanium Foil and Sheet for Industrial Applications

- Graphite Disc Rod and Sheet Electrode Electrochemical Graphite Electrode

- Platinum Sheet Electrode for Laboratory and Industrial Applications

- Isostatic Molding Pressing Molds for Lab

People Also Ask

- Is molybdenum disulfide a heating element? Discover the best material for high-temperature applications.

- What is the function of the heating element in a furnace? The Engine of Your Thermal Process

- How often do heating elements need to be replaced? Maximize Lifespan by Understanding Failure Causes

- Why is the resistance of a heating element high? To Efficiently Convert Electricity into Heat

- What are the advantages of integrating electric heating cartridges with thermocouple control systems? Precision Thermal Control

- What are the high temperature furnace elements to be used in oxidizing environments? Select the Right Element for Your Lab

- What advantages do carbon/carbon (C/C) composite resistors offer? High-Resilience Heating for Si2N2O Synthesis

- What is a silicon carbide heating element? Unlock Extreme Heat for Industrial Processes