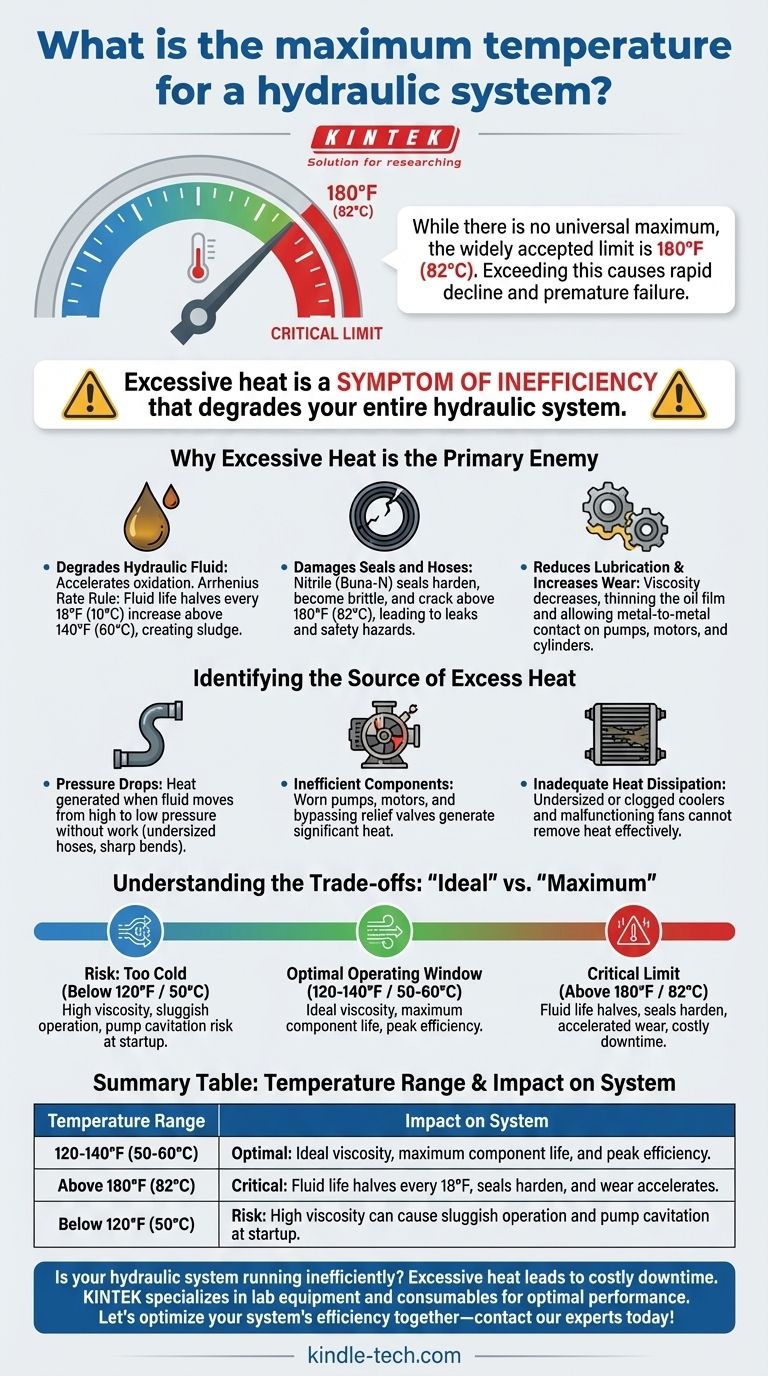

While there is no single universal maximum temperature, the widely accepted operational limit for most industrial hydraulic systems is 180°F (82°C). Exceeding this temperature causes a rapid decline in the lifespan of hydraulic fluid, seals, and hoses, leading to premature system failure.

The critical mistake is focusing on a single "maximum" temperature. The real goal is to maintain a stable and optimal operating range, because excessive heat is not the problem itself—it is a symptom of inefficiency that degrades your entire hydraulic system.

Why Excessive Heat is the Primary Enemy of Hydraulic Systems

Every degree above the optimal range silently reduces your system's reliability and lifespan. Heat represents wasted energy—input power that isn't being converted into useful work.

It Degrades Your Hydraulic Fluid

Heat is the number one enemy of hydraulic oil. It accelerates oxidation, the chemical reaction between oil and oxygen, which is the primary cause of fluid degradation.

A good rule of thumb is the Arrhenius Rate Rule: for every 18°F (10°C) increase in temperature above 140°F (60°C), the oil's service life is cut in half. This oxidation process creates sludge and varnish that can clog filters and stick to valves.

It Damages Seals and Hoses

The most common seal material, Nitrile (Buna-N), is rated for temperatures up to approximately 250°F (121°C). However, prolonged operation at temperatures well below this limit—especially above 180°F (82°C)—will cause the seals to harden, become brittle, and crack.

This leads to both internal and external leaks, reducing system efficiency and creating safety hazards.

It Reduces Lubrication and Increases Wear

As hydraulic oil heats up, its viscosity (resistance to flow) decreases. The oil becomes thinner, and the critical lubricating film between moving parts weakens.

This reduction in lubrication allows for metal-to-metal contact, drastically accelerating wear on expensive components like pumps, motors, and cylinders.

Identifying the Source of Excess Heat

Heat doesn't just appear; it's generated by inefficiency. To control the temperature, you must first understand where the wasted energy is coming from.

Pressure Drops

Any time hydraulic fluid moves from a high-pressure area to a low-pressure area without performing useful work, heat is generated. This can be caused by undersized hoses, sharp bends, or restrictive fittings.

Inefficient Components

Pumps and motors are never 100% efficient. Worn components have greater internal leakage (fluid slipping from the high-pressure side to the low-pressure side), which generates significant heat. A relief valve that is constantly bypassing fluid is a major source of heat.

Inadequate Heat Dissipation

The system's reservoir and heat exchanger (cooler) are responsible for dissipating heat. If a cooler is undersized, clogged with debris, or has a malfunctioning fan, it cannot remove heat effectively, causing the system's overall temperature to rise.

Understanding the Trade-offs: "Ideal" vs. "Maximum"

Focusing on the 180°F (82°C) limit is reactive. Proactive maintenance aims for a much lower, more stable temperature.

The True Cost of Running Hot

Operating near the maximum limit carries a high cost: more frequent fluid and filter changes, unplanned downtime due to seal and hose failure, and accelerated component wear that leads to expensive replacements. It also means you are constantly paying for wasted electricity.

The Optimal Operating Window

For peak performance and maximum component life, most hydraulic systems should operate in the 120°F to 140°F (50°C to 60°C) range. Within this window, the fluid maintains its ideal viscosity, providing excellent lubrication, maximizing efficiency, and dramatically extending the life of all system components.

The Risk of Running Too Cold

It is also possible for a system to run too cold, especially at startup. Oil that is too cold has a very high viscosity, which can lead to sluggish operation and even cavitation (the formation of vapor cavities) that can damage the pump.

Making the Right Choice for Your Goal

Managing your system's temperature is a strategic decision that directly impacts your operational costs and reliability.

- If your primary focus is maximum longevity and efficiency: Aim to operate consistently within the optimal 120-140°F (50-60°C) range to maximize the life of your fluid and seals.

- If you are troubleshooting an overheating system: Investigate the heat exchanger first, then check system pressures to find any significant, unintended pressure drops or relief valves that are constantly bypassing fluid.

- If you are designing a new system: Ensure your heat exchanger is sized to dissipate at least 25-40% of the total input horsepower, as this is the typical amount of energy lost to heat.

Ultimately, managing hydraulic temperature is not about avoiding a single failure point, but about creating an efficient, reliable system that minimizes energy waste and maximizes its operational lifespan.

Summary Table:

| Temperature Range | Impact on System |

|---|---|

| 120-140°F (50-60°C) | Optimal: Ideal viscosity, maximum component life, and peak efficiency. |

| Above 180°F (82°C) | Critical: Fluid life halves every 18°F, seals harden, and wear accelerates. |

| Below 120°F (50°C) | Risk: High viscosity can cause sluggish operation and pump cavitation at startup. |

Is your hydraulic system running inefficiently? Excessive heat is a symptom of wasted energy and leads to costly downtime and component failure. KINTEK specializes in the lab equipment and consumables that keep your operations running smoothly. Our expertise helps laboratories maintain optimal system performance, ensuring reliability and longevity for your critical equipment. Let's optimize your system's efficiency together—contact our experts today for a consultation!

Visual Guide

Related Products

- Manual Lab Heat Press

- Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Heated Hydraulic Press Machine with Integrated Manual Heated Plates for Lab Use

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- Variable Speed Peristaltic Pump

People Also Ask

- How much force can a hydraulic press exert? Understanding its immense power and design limits.

- What is the conclusion of a hydraulic press? Unmatched Force for Industrial Applications

- What is an automatic press machine? High-Precision Force for Modern Manufacturing

- What are the failures of a hydraulic press? Prevent Downtime and Ensure Safety in Your Lab

- What does a manual press do? Understand the Two Key Types for Your Lab or Industrial Needs