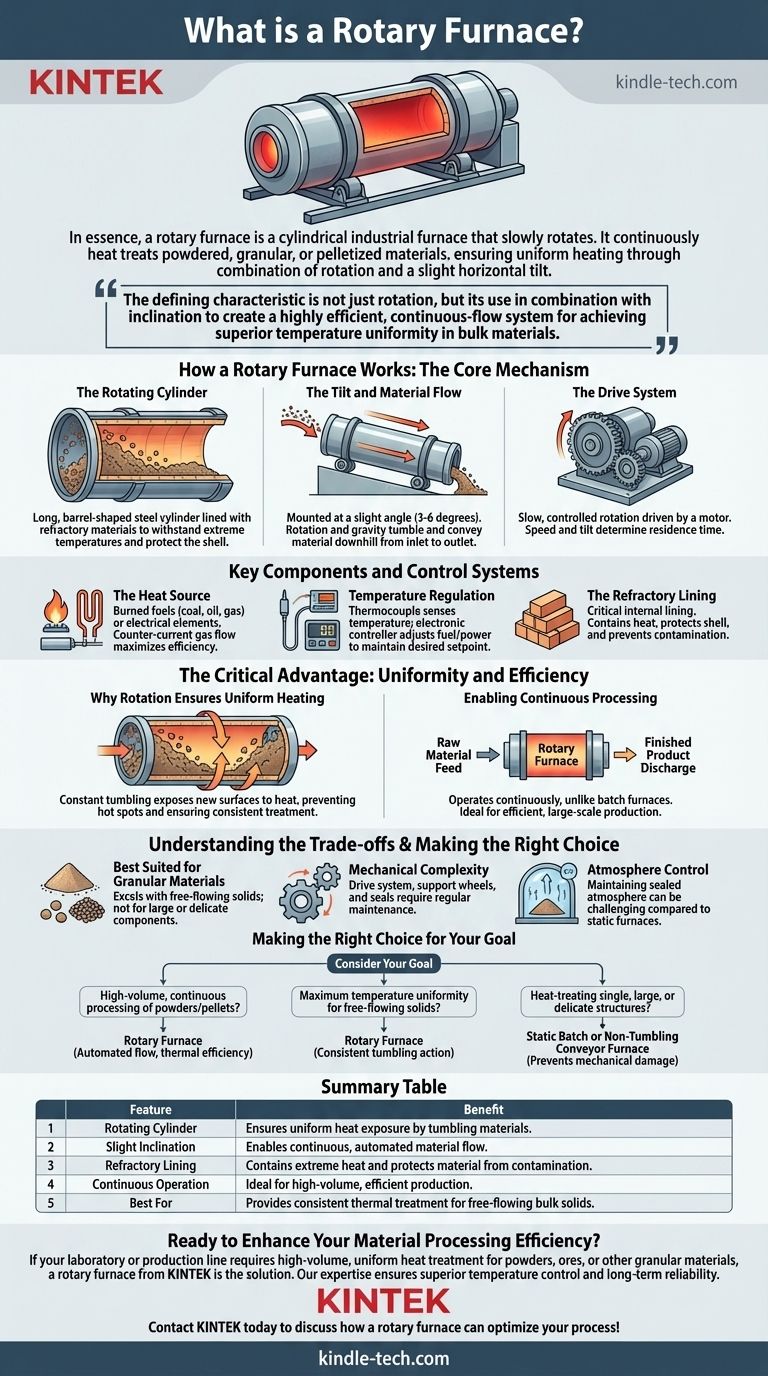

In essence, a rotary furnace is a cylindrical industrial furnace that slowly rotates during operation. It is specifically designed for the continuous heat treatment of materials, often in powdered, granular, or pelletized form. The combination of rotation and a slight horizontal tilt automatically tumbles and conveys the material from the inlet to the outlet, ensuring every particle is heated uniformly.

The defining characteristic of a rotary furnace is not just its rotation, but how it uses that rotation in combination with a slight inclination to create a highly efficient, continuous-flow system for achieving superior temperature uniformity in bulk materials.

How a Rotary Furnace Works: The Core Mechanism

A rotary furnace's design is elegantly simple and highly effective. Its operation is based on the interplay between its physical structure and controlled motion.

The Rotating Cylinder

The main body of the furnace is a long, barrel-shaped steel cylinder. This cylinder is lined with refractory materials—specialized bricks or castable ceramics that can withstand extreme temperatures and protect the outer steel shell.

The Tilt and Material Flow

The furnace is mounted on support wheels and set at a slight angle, typically between 3 and 6 degrees of inclination. As the cylinder rotates slowly, gravity causes the material inside to tumble and gradually move downhill from the higher entry point to the lower exit point.

The Drive System

This slow, controlled rotation is driven by an electric motor connected to a large gear system. The speed of rotation is a critical process parameter that, along with the furnace's tilt angle, determines how long the material stays inside for treatment.

Key Components and Control Systems

While the rotating, tilted cylinder is the heart of the system, several other components are essential for its function as a precise piece of industrial equipment.

The Heat Source

Rotary furnaces can be heated in various ways. They may burn pulverized coal, oil, or gas, with the hot combustion gases flowing through the cylinder, typically in the opposite direction of the material flow (counter-current) for maximum heat transfer efficiency. Electrical heating elements are also used in many modern designs.

Temperature Regulation

To ensure a precise heat treatment process, the furnace temperature is constantly monitored. A thermocouple senses the internal temperature and sends a signal to an electronic controller, which adjusts the fuel supply or electrical power to maintain the desired setpoint.

The Refractory Lining

The internal refractory lining is a critical component. It not only contains the intense heat but also protects the material being processed from contamination by the steel shell and prevents the shell from overheating and losing its structural integrity.

The Critical Advantage: Uniformity and Efficiency

The design of a rotary furnace directly translates into two major advantages over static, or "batch," furnaces.

Why Rotation Ensures Uniform Heating

The constant tumbling motion is the key to uniformity. It continuously exposes new surfaces of the material to the heat source, preventing hot spots and ensuring that every particle receives a consistent thermal treatment from all sides.

Enabling Continuous Processing

Unlike a batch furnace that must be loaded and unloaded for each cycle, a rotary furnace operates continuously. Raw material can be fed into the high end while the finished product is discharged from the low end, making it exceptionally efficient for large-scale production.

Understanding the Trade-offs

While powerful, a rotary furnace is not a universal solution. Understanding its limitations is key to using it correctly.

Best Suited for Granular Materials

This design excels with free-flowing solids like powders, ores, pellets, and aggregates. It is not suitable for large, single components or delicate materials that could be damaged by the tumbling action.

Mechanical Complexity

The drive system, support wheels, and seals required for rotation add a layer of mechanical complexity. These moving parts require regular maintenance to ensure reliable, long-term operation.

Atmosphere Control

While not impossible, maintaining a perfectly sealed, controlled gas atmosphere inside a rotating cylinder with open ends can be more challenging than in a static, sealed chamber furnace.

Making the Right Choice for Your Goal

To determine if a rotary furnace is the correct tool, consider your primary objective.

- If your primary focus is high-volume, continuous processing of powders or pellets: A rotary furnace is the ideal choice due to its automated material flow and thermal efficiency.

- If your primary focus is achieving maximum temperature uniformity for free-flowing solids: The tumbling action of a rotary furnace provides a level of consistency that is difficult to match with static methods.

- If your primary focus is heat-treating single, large components or delicate structures: A static batch furnace or a non-tumbling conveyor furnace is the more appropriate solution to prevent mechanical damage.

By understanding its unique combination of rotation and inclination, you can leverage the rotary furnace for highly efficient and uniform material processing.

Summary Table:

| Feature | Description | Benefit |

|---|---|---|

| Rotating Cylinder | Barrel-shaped furnace that rotates slowly. | Ensures uniform heat exposure by tumbling materials. |

| Slight Inclination | Mounted at a 3-6 degree angle. | Enables continuous, automated material flow from feed to discharge. |

| Refractory Lining | Internal heat-resistant lining. | Contains extreme heat and protects material from contamination. |

| Continuous Operation | Material is fed and discharged constantly. | Ideal for high-volume, efficient production compared to batch furnaces. |

| Best For | Powders, granules, pellets, ores. | Provides consistent thermal treatment for free-flowing bulk solids. |

Ready to Enhance Your Material Processing Efficiency?

If your laboratory or production line requires high-volume, uniform heat treatment for powders, ores, or other granular materials, a rotary furnace from KINTEK is the solution. Our expertise in lab equipment ensures you get a system designed for superior temperature control and long-term reliability.

We specialize in providing the right thermal processing equipment to meet your specific laboratory and industrial needs.

Contact KINTEK today to discuss how a rotary furnace can optimize your process!

Visual Guide

Related Products

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Rotary Tube Furnace Split Multi Heating Zone Rotating Tube Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

- Graphite Vacuum Continuous Graphitization Furnace

People Also Ask

- What are the advantages of pyrolysis and gasification? Choosing the Right Waste-to-Energy Technology

- Why is pyrolysis sustainable? Unlocking a Circular Economy with Waste-to-Value Technology

- What is the temperature of heating pyrolysis? Master the Key to Your Desired Output

- What are the solid products of pyrolysis? Unlock the Value of Biochar and Coke

- What is pyrolysis and why is it important in the combustion process? Unlock the Hidden First Stage of Fire

- What are the disadvantages of flash pyrolysis oil? Overcoming Key Challenges in Bio-Oil Utilization

- What plastics can be used in pyrolysis? A Guide to Ideal Feedstocks for Waste-to-Energy

- Is pyrolysis energy efficient? Unlock a self-sustaining waste-to-energy process