The most common alternative term for sieve analysis is a gradation test. Both terms refer to the same laboratory procedure used to determine the particle size distribution of a granular material like soil, aggregate, sand, or gravel. This analysis is fundamental in geotechnical engineering, construction, and materials science.

Sieve analysis, or a gradation test, is not simply a measurement; it's a critical diagnostic tool. It allows engineers to classify a material and predict its physical behavior, such as its strength, permeability, and compaction characteristics, which are essential for ensuring the safety and performance of a structure.

The Purpose of a Gradation Test

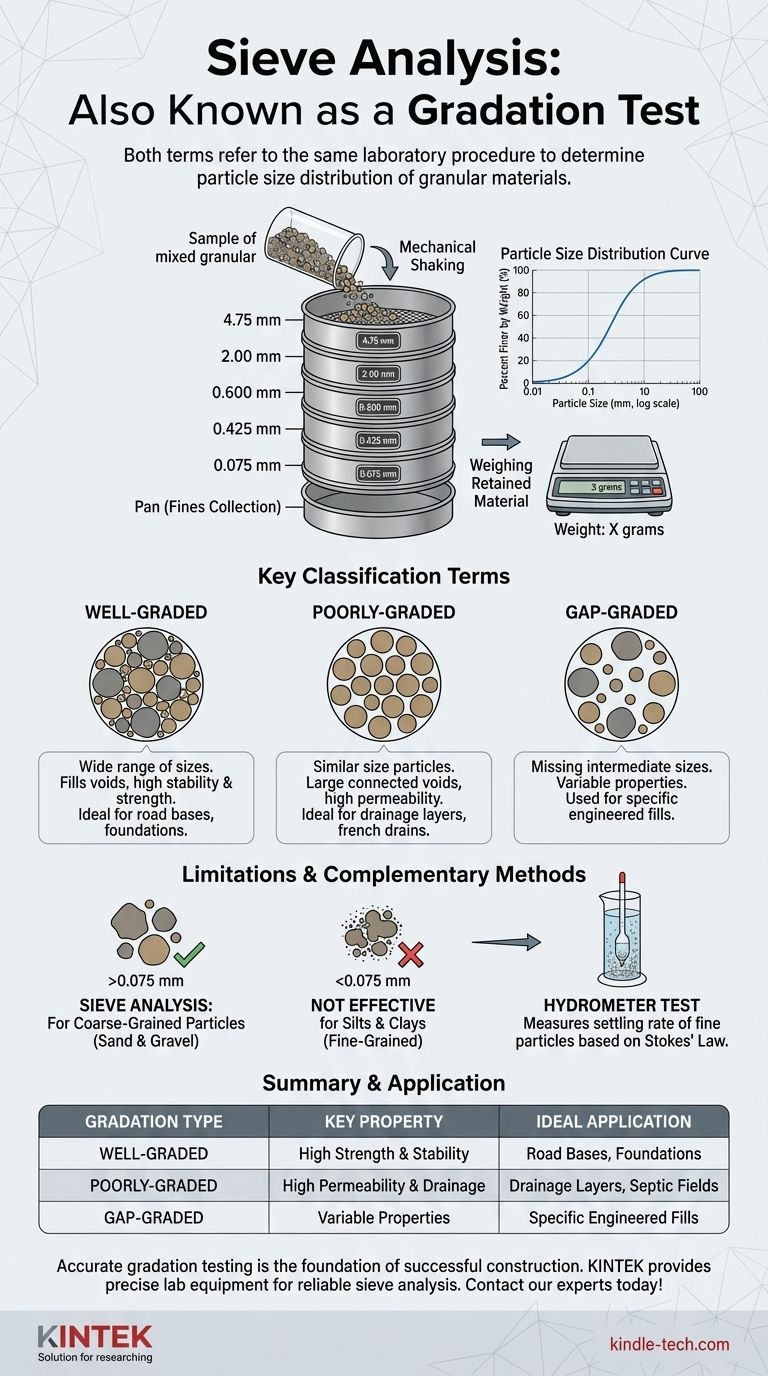

A gradation test is a method for separating a dry material sample into different size fractions. The results are used to plot a particle size distribution curve, which is a graphical representation of how a material's mass is distributed across a range of sizes.

The Core Principle

The procedure involves passing a known mass of material through a stack of sieves, also known as a sieve stack. These are wire mesh screens with precisely sized square openings, arranged from the largest opening at the top to the smallest at the bottom, with a solid pan at the very end to catch the finest particles.

The sieve stack is mechanically shaken for a set period. Afterward, the material retained on each sieve is weighed. This data reveals the percentage of the total sample that falls within specific size ranges.

Key Classification Terms

The shape of the particle size distribution curve leads to critical classifications:

- Well-Graded: The material contains a wide and balanced distribution of particle sizes. These materials tend to compact into a dense state with few voids, providing high stability and strength.

- Poorly-Graded (or Uniformly-Graded): The material consists primarily of particles of a similar size. This creates a structure with large, interconnected voids.

- Gap-Graded: The material is missing one or more intermediate particle sizes. It has coarse particles and fine particles, but few in between.

Why Particle Gradation Matters

The distribution of particle sizes directly controls the engineering properties of the material. Understanding gradation is essential for selecting the right material for a specific application.

Impact on Strength and Stability

A well-graded aggregate or soil will have smaller particles that fill the voids between larger ones. This creates a dense, interlocked structure that is highly stable and can bear significant loads, making it ideal for road bases and structural foundations.

Influence on Permeability and Drainage

A poorly-graded coarse material (like a clean gravel) has large, connected voids. This results in high permeability, allowing water to pass through easily. This property is desirable for drainage layers behind retaining walls or under pavement.

Conversely, a material with a high percentage of fine particles (clays and silts) will have very small voids, leading to low permeability. This is useful for applications that require water containment, such as the core of an earthen dam.

Understanding the Limitations

While incredibly useful, sieve analysis has important limitations. Acknowledging them is key to accurate material characterization.

Not Suitable for Fine-Grained Soils

Sieve analysis is only effective for coarse-grained particles (sand and gravel), which are generally larger than 0.075 mm (the opening of the No. 200 sieve).

Particles smaller than this (silts and clays) tend to clump together due to electrostatic forces, making physical sieving ineffective and inaccurate.

The Role of the Hydrometer Test

For fine-grained soils, a hydrometer test is used. This complementary procedure measures particle size distribution based on the rate at which particles settle in a fluid, governed by Stokes' Law.

A complete particle size distribution for a mixed soil often combines the results of a sieve analysis (for the coarse fraction) and a hydrometer test (for the fine fraction).

Making the Right Choice for Your Goal

The "ideal" gradation depends entirely on your project's objective. Interpreting the results allows you to select the correct material to achieve the desired performance.

- If your primary focus is strength and stability (e.g., concrete mix, road base): You should specify a well-graded material to achieve maximum density and internal friction.

- If your primary focus is high drainage (e.g., septic fields, french drains): You should use a poorly-graded, coarse material to ensure high permeability.

- If your primary focus is low permeability (e.g., landfill liners, dam cores): You need a material with a sufficient amount of fine particles to fill voids and impede water flow.

Ultimately, understanding the particle gradation of a material empowers you to control its performance in any engineering application.

Summary Table:

| Gradation Type | Particle Size Distribution | Key Property | Ideal Application |

|---|---|---|---|

| Well-Graded | Wide range of particle sizes | High Strength & Stability | Road bases, foundations |

| Poorly-Graded | Particles of similar size | High Permeability & Drainage | Drainage layers, septic fields |

| Gap-Graded | Missing intermediate sizes | Variable Properties | Specific engineered fills |

Ready to ensure your materials meet exact specifications?

Accurate gradation testing is the foundation of successful construction and materials science projects. KINTEK provides the precise lab equipment and consumables—including high-quality test sieves—you need for reliable sieve analysis and particle size distribution.

Let us help you achieve optimal material performance. Contact our experts today to discuss your laboratory's specific needs!

Visual Guide

Related Products

- Laboratory Test Sieves and Vibratory Sieve Shaker Machine

- Laboratory Vibratory Sieve Shaker Machine for Dry and Wet Three-Dimensional Sieving

- Three-dimensional electromagnetic sieving instrument

- Laboratory Multifunctional Small Speed-Adjustable Horizontal Mechanical Shaker for Lab

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

People Also Ask

- Why use a vibratory sieve shaker for PET powder? Achieve Precise Particle Size Control for Chemical Research

- Why is a standardized sieving system necessary for elephant grass research? Ensure Reliable Sample Consistency

- What is the significance of using a fine sieving system for catalyst particles? Optimize Size for Maximum Reactivity

- Why is powder classification using standard sieves essential for SHS reactions? Unlock Superior Nitriding Results

- How do high-precision sieving systems benefit zeolite preparation? Maximize Adsorption for Wastewater Treatment