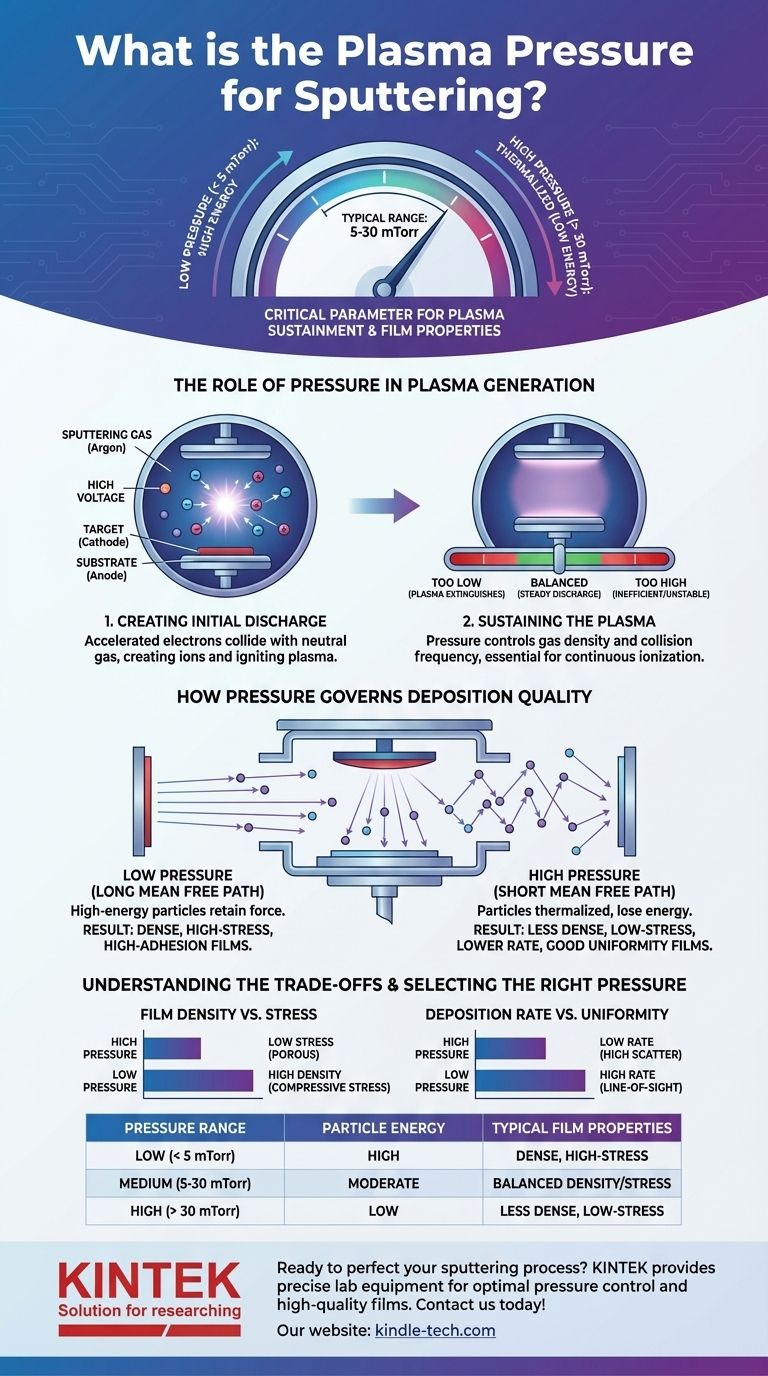

In a typical sputtering process, the plasma pressure is generally maintained within a range of 5 to 30 mTorr. This specific pressure window is not arbitrary; it's a critical parameter for sustaining the plasma discharge and directly influences the energy of the sputtered particles before they form a film on your substrate.

Sputtering pressure is less about a single "correct" number and more about a fundamental trade-off. It dictates the frequency of gas-phase collisions, allowing you to control whether sputtered particles arrive at your substrate with high energy (low pressure) or are "thermalized" to lower energy states (high pressure).

The Role of Pressure in Plasma Generation

To understand the importance of a specific pressure range, we must first look at how the plasma is created and sustained.

Creating the Initial Discharge

The process begins by introducing a low-pressure sputtering gas, typically argon, into a vacuum chamber. A high voltage is then applied between the target material (the cathode) and the chamber/substrate holder (the anode).

This powerful electric field accelerates free electrons, causing them to collide with neutral argon atoms. These collisions are energetic enough to knock electrons off the argon atoms, creating positively charged argon ions and more free electrons, which ignites the plasma.

Sustaining the Plasma

For the plasma to remain stable, this ionization process must be continuous. The chamber pressure directly controls the density of gas atoms available for collision.

If the pressure is too low, there are too few gas atoms. An electron can travel a long distance without causing an ionizing collision, and the plasma will extinguish.

If the pressure is too high, the process can become inefficient or unstable. The key is to find the right balance to maintain a steady, self-sustaining plasma discharge.

How Pressure Governs Deposition Quality

The most critical function of pressure is its effect on the sputtered particles after they leave the target and travel toward your substrate.

The Concept of Mean Free Path

Mean free path is the average distance a particle travels before colliding with another particle. This concept is central to sputtering.

At low pressure, the mean free path is long. Sputtered atoms travel from the target to the substrate with few, if any, collisions.

At high pressure, the mean free path is short. Sputtered atoms will undergo many collisions with the background gas atoms before reaching the substrate.

Low-Pressure Sputtering (< 5 mTorr)

Operating at lower pressures results in a more "line-of-sight" deposition. Particles retain most of the high energy they had when they were ejected from the target.

This high-energy bombardment leads to denser, more compact thin films. The added energy promotes atom mobility on the substrate surface, filling in voids and creating a higher-quality film structure.

High-Pressure Sputtering (5-30+ mTorr)

As you increase pressure, the sputtered particles are "thermalized." Through multiple collisions with the sputtering gas, they lose kinetic energy.

These lower-energy particles arrive at the substrate with much less force. This typically results in films that are less dense and have lower intrinsic stress. This can be advantageous for coating delicate substrates or for applications where film stress is a concern.

Understanding the Trade-offs

Choosing a pressure is an exercise in balancing competing factors. What you gain in one area, you often sacrifice in another.

Film Density vs. Internal Stress

This is the primary trade-off. Low pressure yields high-density films but often with high compressive stress, which can cause delamination. High pressure produces lower-stress films that may be more porous or have lower adhesion.

Deposition Rate vs. Uniformity

At higher pressures, particles are scattered more randomly. This scattering can improve the thickness uniformity of the film across a large or complex-shaped substrate.

However, this same scattering effect means fewer particles travel directly to the substrate, which almost always results in a lower deposition rate.

Selecting the Right Pressure for Your Goal

There is no single "best" pressure. The optimal value is determined entirely by the desired properties of your final thin film.

-

If your primary focus is a dense, hard, or highly adherent film: Start with a lower pressure to maximize the energy of the depositing particles.

-

If your primary focus is a low-stress film or coating a delicate substrate: Use a higher pressure to thermalize the sputtered atoms and reduce their impact energy.

-

If your primary focus is maximizing uniformity over a large area: A moderate to higher pressure may be beneficial due to the increased particle scattering.

Ultimately, mastering sputtering pressure is about understanding it not as a static setting, but as a dynamic tool to precisely engineer the properties of your thin film.

Summary Table:

| Pressure Range | Effect on Sputtered Particles | Typical Film Properties |

|---|---|---|

| Low (< 5 mTorr) | Few collisions; high-energy particles | Dense, high-stress, high adhesion |

| Medium (5-30 mTorr) | Moderate collisions; thermalized particles | Balanced density and stress, good uniformity |

| High (> 30 mTorr) | Many collisions; low-energy particles | Less dense, low stress, lower deposition rate |

Ready to perfect your sputtering process? The right lab equipment is key to achieving precise pressure control and consistent, high-quality thin films. KINTEK specializes in lab equipment and consumables, serving all your laboratory needs. Our experts can help you select the ideal sputtering system for your application. Contact us today to discuss your project and optimize your deposition results!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

People Also Ask

- What is the principle of plasma enhanced chemical vapor deposition? Achieve Low-Temperature Thin Film Deposition

- How are PECVD and CVD different? A Guide to Choosing the Right Thin-Film Deposition Process

- What are the applications of PECVD? Essential for Semiconductors, MEMS, and Solar Cells

- Why does PECVD commonly use RF power input? For Precise Low-Temperature Thin Film Deposition

- What are the benefits of PECVD? Achieve Superior Low-Temperature Thin Film Deposition