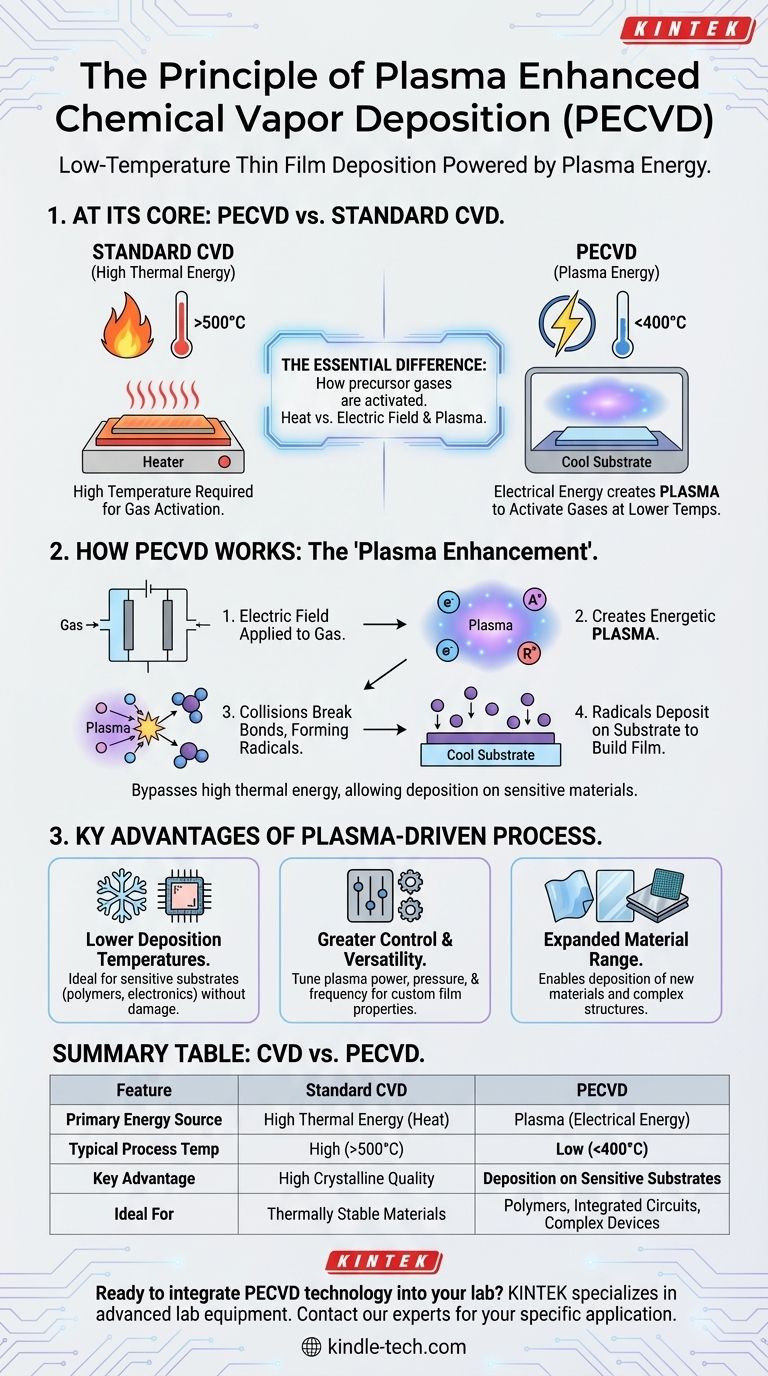

At its core, the principle of Plasma Enhanced Chemical Vapor Deposition (PECVD) is the use of electrical energy to generate a plasma, which then provides the energy to drive chemical reactions for thin film deposition. This plasma—an energized gas of ions, electrons, and radicals—replaces the high thermal energy required in traditional Chemical Vapor Deposition (CVD), allowing high-quality films to be grown at much lower temperatures.

The essential difference is how the precursor gases are activated. While standard CVD uses heat to break down molecules, PECVD uses an electric field to create a plasma that breaks them down, enabling a low-temperature process ideal for sensitive materials.

The Foundation: Understanding Standard CVD

To grasp the innovation of PECVD, one must first understand the conventional process it enhances.

The Core Process: Gas to Solid

Chemical Vapor Deposition (CVD) is a method for depositing solid, high-performance thin films onto a surface, known as a substrate.

The process involves introducing one or more precursor gases into a reaction chamber under controlled pressure and temperature.

These gases undergo a chemical reaction directly on the substrate's surface, decomposing and forming a solid layer. Gaseous by-products are then removed from the chamber.

The Critical Role of High Temperature

In standard CVD, the energy required to initiate this chemical reaction and break the chemical bonds of the precursor gases is supplied by heat.

The substrate is typically heated to very high temperatures, often several hundred or even over a thousand degrees Celsius. This thermal energy is the catalyst for the entire deposition process.

The "Plasma Enhancement": How PECVD Changes the Game

PECVD fundamentally alters the energy source, overcoming the limitations of high-temperature requirements.

What is Plasma?

Plasma is often called the fourth state of matter. It is a gas that has been energized, typically by a strong electric or magnetic field, to the point where its atoms are broken apart.

This creates a highly reactive mixture of free electrons, positively charged ions, and neutral but unstable fragments called radicals.

Bypassing Thermal Energy

In PECVD, instead of heating the substrate to extreme temperatures, energy is supplied through an electric field applied to the precursor gas.

This energy creates the plasma. The highly energetic electrons and ions within the plasma collide with the precursor gas molecules.

These collisions have enough energy to break the molecular bonds, creating the same reactive radicals that high temperatures would, but without needing a hot substrate.

The Deposition Mechanism

Once these highly reactive radicals are formed within the plasma, they are drawn to the relatively cool substrate surface.

There, they readily react and bond to the surface, building the desired thin film layer by layer, just as in traditional CVD.

Key Advantages of the Plasma-Driven Process

The shift from thermal to plasma-based energy provides several critical advantages that make PECVD a vital manufacturing technique.

Lower Deposition Temperatures

This is the most significant benefit. By avoiding the need for extreme heat, PECVD can be used to deposit films on temperature-sensitive substrates.

This includes plastics, polymers, and complex electronic devices with pre-existing components that would be damaged or destroyed by the heat of a standard CVD process.

Greater Control and Versatility

PECVD introduces new process variables that can be precisely tuned, such as plasma power, frequency, and gas pressure.

This additional control allows for the fine-tuning of the resulting film's properties, including its density, stress, and chemical composition, expanding the range of possible materials and applications.

Making the Right Choice for Your Goal

The decision between standard CVD and PECVD hinges entirely on the thermal tolerance of your substrate and the desired properties of the final film.

- If your primary focus is depositing on heat-sensitive materials like polymers or integrated circuits: PECVD is the necessary choice, as its low-temperature nature prevents substrate damage.

- If your primary focus is achieving the highest possible crystalline quality in a thermally stable material: High-temperature thermal CVD may still be preferred, as it can sometimes produce films with superior structural order.

- If your primary focus is fine-tuning film properties like stress or density: The additional control parameters offered by the plasma in a PECVD system provide a significant advantage.

Ultimately, understanding that plasma serves as a low-temperature energy substitute for heat is the key to selecting the right deposition technology for your specific application.

Summary Table:

| Feature | Standard CVD | PECVD |

|---|---|---|

| Primary Energy Source | High Thermal Energy | Plasma (Electrical Energy) |

| Typical Process Temperature | High (Often > 500°C) | Low (Often < 400°C) |

| Key Advantage | High Crystalline Quality | Deposition on Sensitive Substrates |

| Ideal For | Thermally Stable Materials | Polymers, Integrated Circuits, Complex Devices |

Ready to integrate PECVD technology into your lab?

KINTEK specializes in providing advanced lab equipment and consumables for cutting-edge research and manufacturing. Our expertise in deposition technologies like PECVD can help you:

- Protect temperature-sensitive substrates like polymers and pre-fabricated electronics.

- Gain precise control over film properties such as density and stress.

- Enhance your R&D or production capabilities with reliable, high-performance systems.

Let our experts help you select the ideal solution for your specific application. Contact KINTEK today to discuss your laboratory needs!

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

People Also Ask

- How does PECVD work? Enable Low-Temperature, High-Quality Thin Film Deposition

- What is plasma chemical vapor deposition technique? Enable Low-Temperature, High-Quality Thin Film Coatings

- What are the applications of DLC coating? Enhance Wear, Friction, and Performance for Your Components

- Why is a high vacuum system essential for PECVD DLC coatings? Ensure Film Purity and Structural Density

- What is plasma enhanced chemical vapour deposition process? Unlock Low-Temperature, High-Quality Thin Films

- What is the role of RF-PECVD in VFG preparation? Mastering Vertical Growth and Surface Functionality

- How is PECVD different from CVD? Unlock Low-Temperature Thin Film Deposition

- Is DLC scratch proof? Discover the Truth About Its Exceptional Scratch Resistance