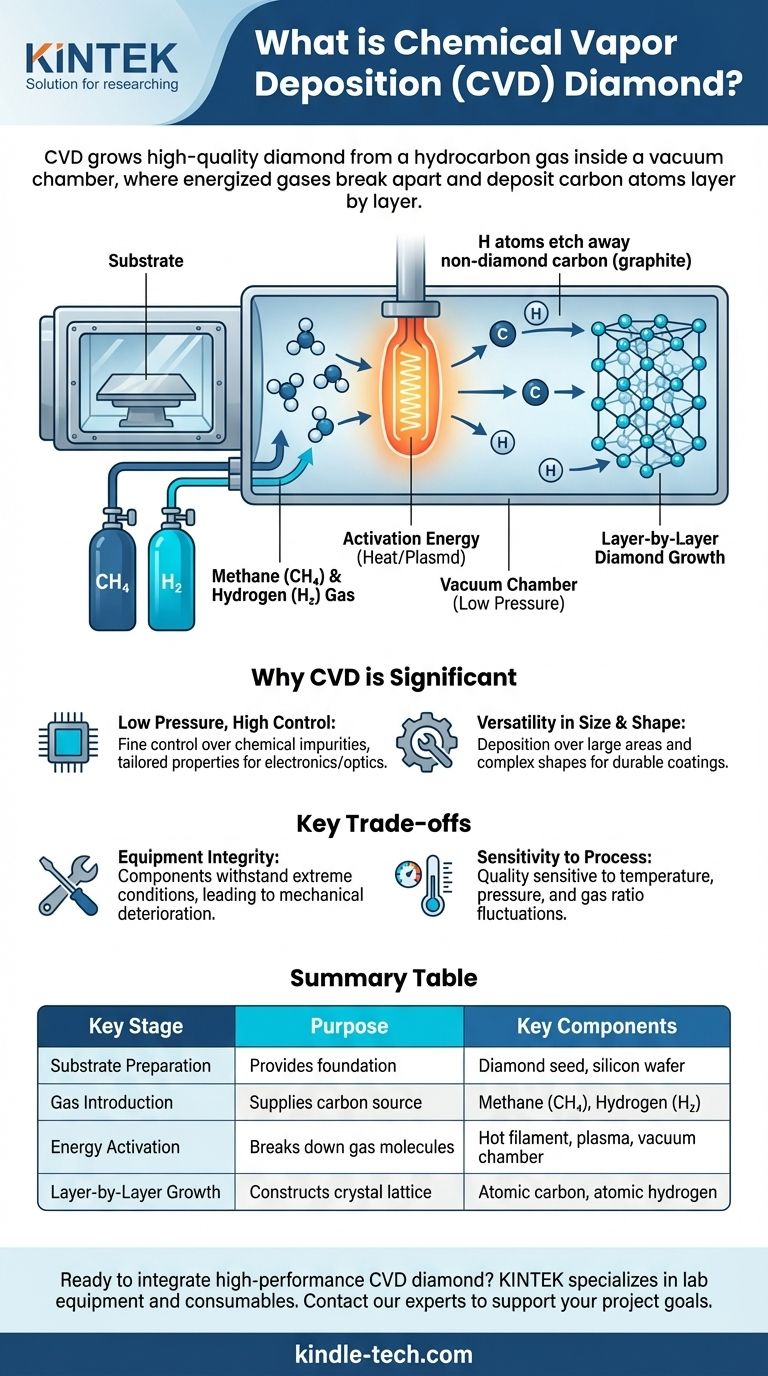

In essence, Chemical Vapor Deposition (CVD) for diamonds is a process that grows a high-quality diamond from a hydrocarbon gas. Inside a vacuum chamber, a mixture of gases, typically methane and hydrogen, is energized, causing the gas molecules to break apart. The resulting carbon atoms then deposit onto a substrate, building a diamond crystal layer by layer.

The core principle of diamond CVD is not about compressing existing carbon, but about methodically constructing a diamond, atom by atom, from a gaseous source. This allows for exceptional control over the diamond's purity, properties, and the shape of the final product.

The Fundamental Principles of Diamond CVD

To understand how a gas transforms into one of the world's hardest materials, we must break the process down into its core components and stages. Each step is precisely controlled to ensure the carbon atoms arrange themselves into the correct crystalline diamond structure.

The Core Ingredients: The Substrate and the Gas

The process begins with a substrate, which is a small, flat piece of material that acts as the foundation for growth. This could be a small diamond seed or another material like silicon.

This substrate is placed inside the reaction chamber, which is then filled with a precise mixture of precursor gases. For diamond growth, this is almost always a combination of a carbon source like methane (CH₄) and an excess of hydrogen (H₂) gas.

Creating the Right Environment: The Vacuum Chamber

The entire process occurs within a sealed vacuum chamber. The vacuum is critical for two reasons: it removes any existing air and potential contaminants, and it allows for precise control over the pressure.

Diamond CVD typically operates at very low pressures, often below that of the Earth's atmosphere. This controlled, clean environment is essential for growing high-purity diamond without defects.

The Activation Energy: Heat and Plasma

The gas mixture alone will not form a diamond. It requires a significant amount of energy to break the molecular bonds of the methane and hydrogen gas. This "activation" is usually achieved with heat.

In a common method known as Hot Filament CVD (HFCVD), a filament made of a refractory metal like tungsten is heated to over 2000°C (3632°F). This intense heat dissociates the gas molecules into reactive atomic species, including carbon atoms and atomic hydrogen.

The Growth Process: Atom by Atom

Once the gases are broken down, the carbon atoms deposit onto the cooler, pre-heated substrate. Under the right conditions, these carbon atoms link together in the specific tetrahedral lattice that defines a diamond crystal.

The excess hydrogen gas plays a crucial role here. It selectively etches away any non-diamond carbon (like graphite) that might try to form, ensuring only the high-quality diamond structure remains and continues to grow.

Why CVD is a Significant Process for Diamond Growth

The development of CVD has been revolutionary, offering a powerful alternative to the traditional High-Pressure, High-Temperature (HPHT) method, which mimics the natural diamond formation process.

Low Pressure, High Control

Unlike the immense force required for HPHT, CVD builds diamonds in a low-pressure environment. This gives scientists and engineers exceptionally fine control over chemical impurities.

By introducing other gases during the process, the diamond's properties (like color, conductivity, and thermal resistance) can be precisely tailored for specific applications, from gemstones to advanced electronics.

Versatility in Size and Shape

Because CVD is a deposition process, it can be used to grow diamond over large areas and coat various underlying substrates and complex shapes. This makes it invaluable for industrial applications where a hard, wear-resistant diamond coating is needed on cutting tools or mechanical parts.

Understanding the Key Trade-offs

While powerful, the CVD process is not without its technical challenges and limitations. Understanding these trade-offs is key to appreciating its applications.

The Challenge of Equipment Integrity

The components inside the CVD reactor must withstand extreme conditions. In HFCVD, for example, the intensely hot filament that activates the gases is subject to constant chemical attack and thermal stress.

Over time, this leads to mechanical deterioration, requiring careful maintenance and replacement of critical parts to ensure consistent quality.

Sensitivity to Process Parameters

The final quality of the diamond is extremely sensitive to the process conditions. Small fluctuations in temperature, pressure, or gas mixture ratios can lead to the formation of defects or lower-quality, non-diamond carbon. This requires sophisticated control systems and monitoring.

How to Apply This to Your Goal

The decision to use or specify a CVD diamond product depends entirely on the desired outcome.

- If your primary focus is high-purity material for electronics or optics: CVD is the superior choice due to its unparalleled control over impurities and crystal structure.

- If your primary focus is applying a durable coating to a large or complex part: CVD's ability to deposit a uniform diamond layer over various substrates makes it the ideal technology.

- If your primary focus is producing bulk diamond material with less emphasis on purity: The traditional HPHT method may be a more economically viable or faster alternative.

Ultimately, Chemical Vapor Deposition empowers us to engineer diamond material with properties tuned for a specific purpose, transforming a simple gas into a material of extraordinary performance.

Summary Table:

| Key Stage | Purpose | Key Components |

|---|---|---|

| Substrate Preparation | Provides a foundation for diamond crystal growth | Diamond seed, silicon wafer |

| Gas Introduction | Supplies carbon source for diamond formation | Methane (CH₄), Hydrogen (H₂) |

| Energy Activation | Breaks down gas molecules into reactive atoms | Hot filament, plasma, vacuum chamber |

| Layer-by-Layer Growth | Constructs the diamond crystal lattice | Atomic carbon, atomic hydrogen (etches impurities) |

Ready to integrate high-performance CVD diamond into your lab or production line? KINTEK specializes in lab equipment and consumables, serving the precise needs of laboratories and R&D facilities. Our expertise can help you select the right tools and materials to leverage the unique properties of engineered diamonds for your specific application—whether it's for advanced electronics, durable coatings, or high-purity optics. Contact our experts today to discuss how we can support your project goals.

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- CVD Diamond for Thermal Management Applications

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Microwave Plasma Chemical Vapor Deposition MPCVD Machine System Reactor for Lab and Diamond Growth

- CVD Diamond Domes for Industrial and Scientific Applications

People Also Ask

- What are the physical characteristics of synthetic diamonds? Identical to Natural Diamonds, Made in a Lab

- Are CVD diamonds fake? Discover the Truth About Lab-Grown Diamonds

- What is a diamond machine? Unlock the Power of Diamond Tooling for Your Toughest Materials

- What is the function of the vacuum pump system during high-pressure MPCVD for DLC films? Optimize Purity and Stability

- Can lab-grown diamonds be GIA certified? Yes, and here’s what you need to know.

- What are the advantages of diamond cutting tool material? Achieve Superior Precision and Productivity

- What is the process for CVD diamond? Building a Diamond Atom by Atom

- What are diamond coated films? Enhance Materials with Super-Hard, Transparent Layers