In essence, the pyrolysis of tires is a high-temperature process that breaks down scrap tires in an oxygen-free environment. This thermal decomposition converts the complex organic materials in the rubber into three primary products: a synthetic liquid oil, a solid carbon-rich char, and a combustible gas. The process also allows for the recovery of the steel wires embedded within the tires.

At its core, tire pyrolysis is not simply waste disposal; it is a resource recovery technology. It deconstructs a problematic waste stream back into its valuable constituent components—oil, carbon, steel, and gas—transforming an environmental liability into a source of marketable commodities.

The Core Principle: Thermal Decomposition Without Oxygen

Tire pyrolysis is a form of thermolysis, meaning decomposition brought about by high heat. The entire process hinges on one critical factor: the absence of oxygen.

This is not burning or incineration. Instead, think of it as "cooking" the tires in a sealed, inert chamber. Without oxygen, the long hydrocarbon chains that make up the tire's rubber cannot combust. Instead, the intense heat (typically 400-600°C) breaks these chains apart into smaller, more volatile molecules.

A Step-by-Step Breakdown of the Tire Pyrolysis Process

The conversion of a whole tire into its constituent parts is a systematic, multi-stage industrial process.

Step 1: Feedstock Preparation

Before any thermal processing can begin, the tires must be prepared. Whole tires are inefficient to process and contain non-rubber materials that must be removed.

This stage typically involves heavy-duty shredders that cut the tires into smaller, uniform-sized chips (around 1-2 inches). During or after shredding, powerful magnets and screens are used to separate the steel wires and textile fibers from the rubber. This recovered steel is a valuable co-product.

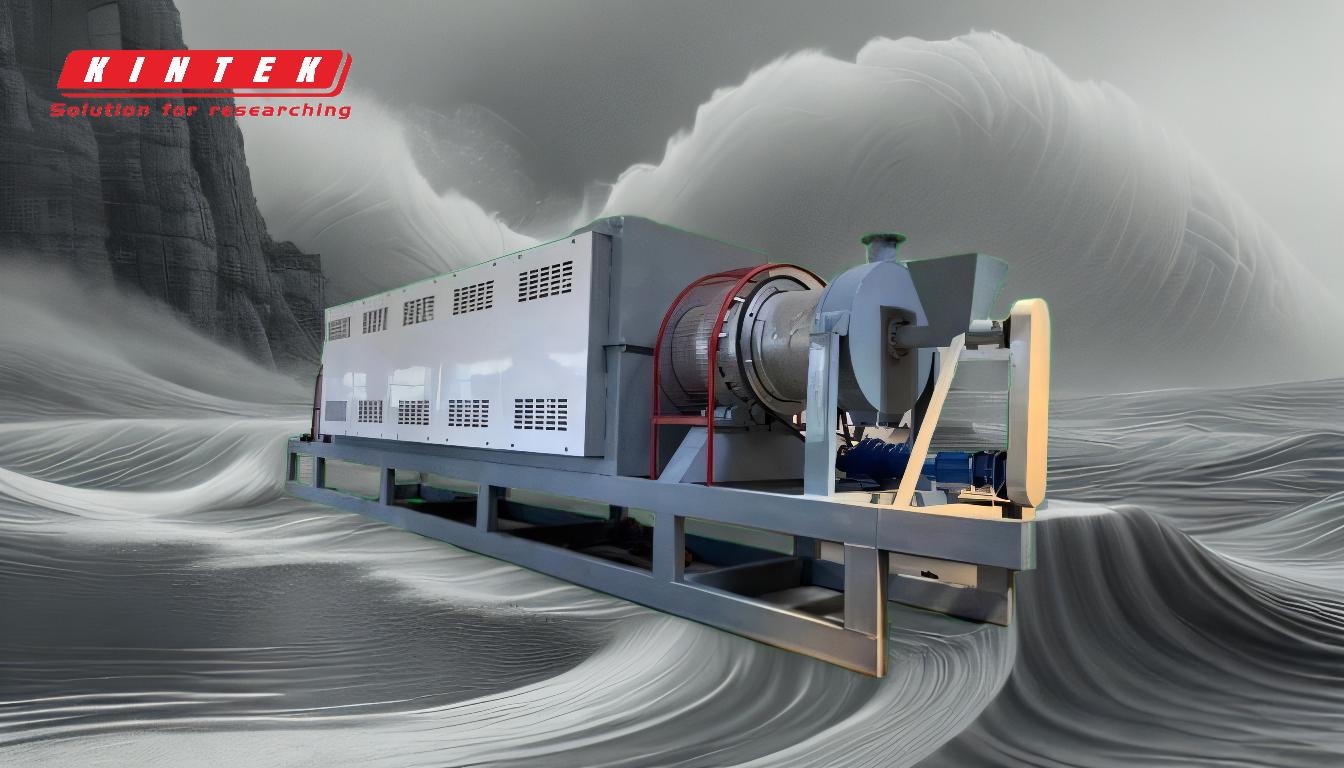

Step 2: The Pyrolysis Reactor

The prepared rubber chips are fed into a sealed, oxygen-free reactor. As the reactor heats up, the rubber begins to vaporize and decompose.

The specific design of the reactor can vary (e.g., rotary kiln, fixed bed), but its function is the same: to provide a controlled, high-temperature environment that efficiently transfers heat to the rubber feedstock, driving the chemical breakdown.

Step 3: Separation and Condensation

A hot stream of vapor exits the reactor. This vapor is a mixture of long-chain hydrocarbons (which will become oil) and short-chain, non-condensable gases.

This stream is directed through a series of condensers and cooling pipes. As the vapor cools, the heavier hydrocarbon molecules condense into a liquid—pyrolysis oil. The remaining gases that do not condense are collected separately as syngas.

Step 4: Product Collection and Refinement

The process yields four distinct product streams that are collected for use or sale:

- Pyrolysis Oil: A synthetic crude oil.

- Recovered Carbon Black (rCB): The solid char left in the reactor.

- Syngas: The non-condensable gas.

- Recovered Steel: Separated during pre-processing.

Understanding the Outputs: From Waste to Value

The economic viability of tire pyrolysis depends on the quality and marketability of its outputs.

Pyrolysis Oil (TPO)

This dark, viscous liquid is similar in composition to industrial fuel oil. It can be used directly as a fuel for boilers and furnaces or be further refined into more valuable products like diesel or gasoline.

Recovered Carbon Black (rCB)

This solid, carbon-rich residue is the "char" left behind after pyrolysis. While its quality can vary, rCB can be used as a pigment, a reinforcing filler in rubber products, or as a solid fuel (similar to coal). High-grade rCB can partially substitute for virgin carbon black in some applications.

Syngas

This mixture of combustible gases (like hydrogen, methane, and carbon monoxide) has a significant energy value. Most modern pyrolysis plants use this gas to fuel the burners that heat the reactor, creating a self-sustaining energy loop and dramatically reducing external energy costs.

Recovered Steel

The high-tensile steel wire recovered from the tires is a clean, easily recyclable commodity that is sold to steel mills.

Understanding the Trade-offs and Challenges

While promising, tire pyrolysis is a complex industrial process with practical challenges that must be managed.

Product Quality and Consistency

The market value of pyrolysis oil and rCB is highly dependent on their quality. This quality can be affected by the type and condition of the input tires, as well as the precise control of temperature and processing time in the reactor. Achieving consistent, high-grade output is a primary operational goal.

Feedstock Contamination

The presence of moisture, dirt, and other non-tire materials in the feedstock can lower the efficiency of the reactor and contaminate the final products. Thorough pre-processing is critical to mitigate this.

Environmental Controls

Like any thermal process, pyrolysis has the potential to generate harmful emissions if not properly managed. A robust system for capturing and treating off-gases is essential for both environmental compliance and operational safety.

Making the Right Choice for Your Goal

The emphasis of a tire pyrolysis operation can be tailored to meet different strategic objectives.

- If your primary focus is resource recovery: Your goal is maximizing the quality of the oil and rCB through precise temperature control and feedstock purity.

- If your primary focus is waste management: The key benefit is the immense volume reduction of scrap tires, converting a landfill burden into manageable, storable commodities.

- If your primary focus is energy production: The process can be optimized to produce more syngas, allowing the plant to be energy self-sufficient or even a net exporter of energy.

Ultimately, tire pyrolysis provides a powerful method for turning a global waste problem into a circular-economy solution.

Summary Table:

| Stage | Key Action | Primary Output(s) |

|---|---|---|

| 1. Preparation | Shredding & separating steel/fibers | Clean rubber chips, Recovered steel |

| 2. Pyrolysis | Heating chips in oxygen-free reactor | Vaporized hydrocarbons, Solid char |

| 3. Condensation | Cooling the hot vapor stream | Pyrolysis Oil (TPO), Syngas |

| 4. Collection | Gathering all product streams | TPO, Recovered Carbon Black (rCB), Syngas, Steel |

Ready to transform your tyre waste into profit? The efficiency and success of a pyrolysis operation depend on robust, reliable equipment. KINTEK specializes in high-performance lab and industrial equipment for material testing and process optimization. Whether you're researching pyrolysis parameters or scaling up production, our solutions can help you achieve consistent, high-quality outputs. Contact our experts today to discuss how we can support your tyre recycling and resource recovery goals.

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Rubber Vulcanizer Vulcanizing Machine Plate Vulcanizing Press for Lab

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- Mini SS High Pressure Autoclave Reactor for Laboratory Use

- Stainless High Pressure Autoclave Reactor Laboratory Pressure Reactor

People Also Ask

- What are the raw materials for biochar production? Choose the Right Feedstock for Your Goals

- What is a disadvantage of biomass energy? The Hidden Environmental and Economic Costs

- What is a pyrolysis furnace? A Tool for Converting Waste into Valuable Resources

- What are the problems with biomass pyrolysis? High Costs & Technical Hurdles Explained

- What is a biomass pyrolysis plant? Turn Waste into Renewable Energy & Biochar