At its core, sputtering is a physical process used to deposit exceptionally thin and uniform layers of a material onto a surface. The technique uses high-energy ions, typically from an inert gas like Argon, to physically knock atoms off a source material (the "target"), which then travel and condense onto the object you wish to coat (the "substrate"), forming a high-quality film.

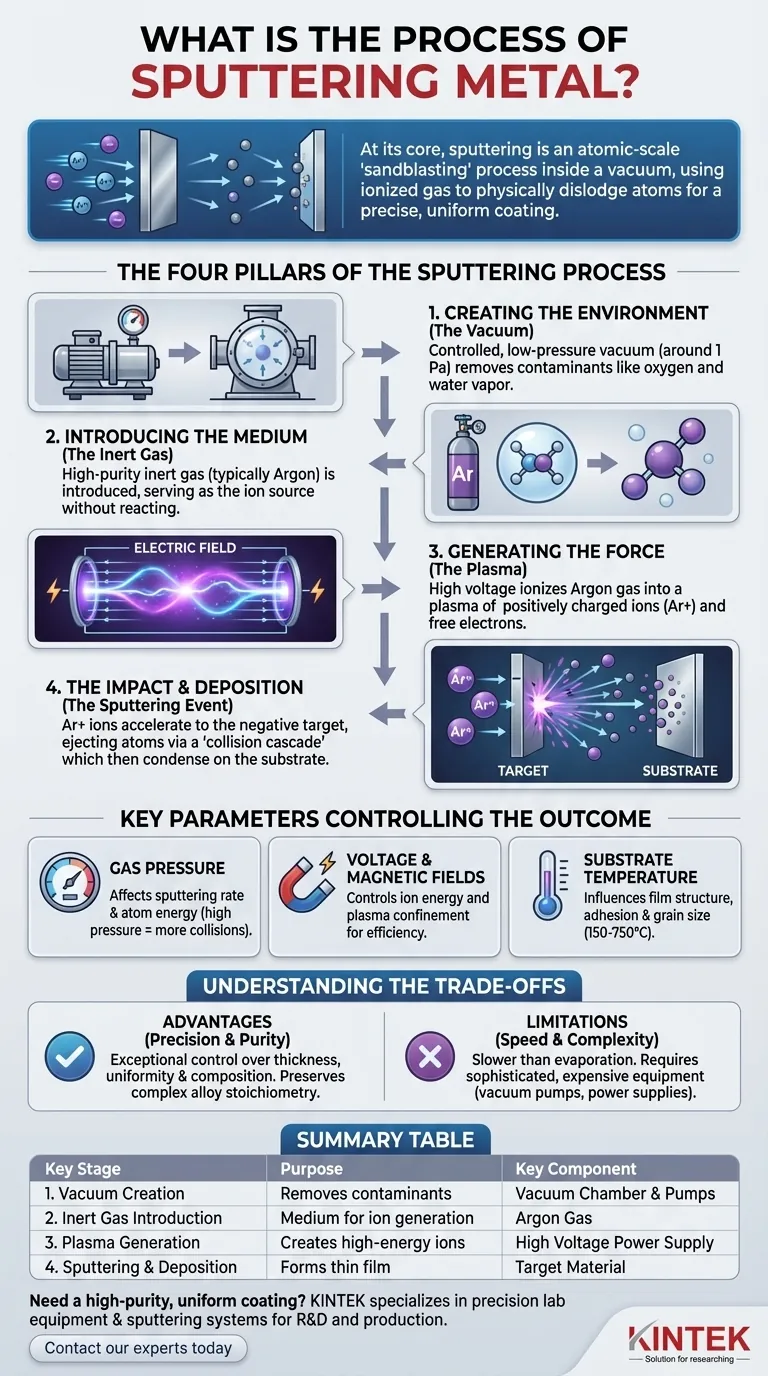

Sputtering is best understood as an atomic-scale "sandblasting" process inside a vacuum. Instead of sand, it uses ionized gas to bombard a source material, precisely dislodging individual atoms that then re-deposit as a highly controlled coating on another surface.

The Four Pillars of the Sputtering Process

To truly understand sputtering, it's best to break it down into four distinct, sequential stages. Each stage is critical for achieving the high-purity and high-precision films this technique is known for.

Step 1: Creating the Environment (The Vacuum)

The entire process must occur in a controlled, low-pressure environment. A vacuum chamber is pumped down to a very low pressure (around 1 Pa or lower) before the process begins.

This step is non-negotiable for two reasons. First, it removes residual gases like oxygen and water vapor that could contaminate the film and react with the coating material. Second, it allows the sputtered atoms to travel from the target to the substrate without colliding with other gas molecules.

Step 2: Introducing the Medium (The Inert Gas)

Once a stable vacuum is achieved, a high-purity inert gas is introduced into the chamber. Argon is the most common choice.

This gas does not react with the target or substrate material. Its sole purpose is to serve as the source of the high-energy ions that will drive the sputtering process.

Step 3: Generating the Force (The Plasma)

A high voltage is applied within the chamber, creating a powerful electric field. This energy strips electrons from the Argon gas atoms, ionizing them and creating a glowing plasma.

This plasma is a mix of positively charged Argon ions (Ar+) and free electrons. In many systems, magnetic fields are also used to confine this plasma close to the target, increasing the efficiency of the process.

Step 4: The Impact and Deposition (The Sputtering Event)

The source material, or target, is given a strong negative charge. This causes the positively charged Argon ions from the plasma to accelerate violently towards it.

These ions strike the target with significant kinetic energy. This impact sets off a "collision cascade," transferring momentum to the target's atoms. If the energy transferred is greater than the bonding energy holding the atoms together, atoms are ejected from the target's surface.

These ejected, neutral particles travel through the vacuum chamber and land on the substrate, where they condense and slowly build up, layer by layer, to form a thin, uniform film.

Key Parameters That Control the Outcome

The final properties of the sputtered film—such as its thickness, density, and adhesion—are not accidental. They are precisely managed by controlling several key parameters during the process.

Gas Pressure

The pressure of the inert gas inside the chamber affects both the sputtering rate and the energy of the sputtered atoms. Higher pressure can increase the rate but may also lead to more collisions, affecting film quality.

Voltage and Magnetic Fields

The applied voltage directly controls the energy of the ions striking the target, which influences how many atoms are ejected per ion impact. Magnetic fields help concentrate the plasma, making the process more efficient and allowing it to run at lower pressures.

Substrate Temperature

The temperature of the substrate being coated can be controlled to influence the film's final structure. Heating the substrate (from 150 to 750°C) can improve adhesion and affect properties like grain size and density.

Understanding the Trade-offs

Like any technical process, sputtering has distinct advantages and limitations that make it suitable for specific applications.

Advantage: Precision and Purity

Sputtering allows for exceptional control over film thickness, uniformity, and composition. Because the target material is transferred without being melted, even complex alloys and compounds can be deposited with their original stoichiometry intact.

Limitation: Deposition Speed

Compared to thermal methods like evaporation, sputtering is generally a slower process. This can make it less suitable for applications requiring very thick films or extremely high throughput.

Consideration: System Complexity

Sputtering systems are sophisticated machines requiring high-vacuum pumps, high-voltage power supplies, gas handling systems, and often, magnetrons. This makes the equipment more complex and expensive than simpler deposition techniques.

Making the Right Choice for Your Goal

Deciding whether sputtering is the correct deposition method depends entirely on the required characteristics of your final film.

- If your primary focus is high-purity, uniform coatings: Sputtering offers unparalleled control over film properties, making it ideal for microelectronics, optical filters, and medical devices.

- If your primary focus is coating complex alloys or refractory metals: Sputtering excels because it physically transfers the target material's composition directly to the substrate without melting.

- If your primary focus is rapid, high-volume deposition of simple metals: You may need to evaluate the trade-off between sputtering's quality and the higher speed of alternative methods like thermal evaporation.

Ultimately, sputtering is the definitive choice when precision, purity, and control over the final film's properties are the most critical factors for success.

Summary Table:

| Key Stage | Purpose | Key Component |

|---|---|---|

| 1. Vacuum Creation | Removes contaminants for a pure environment | Vacuum Chamber & Pumps |

| 2. Inert Gas Introduction | Provides medium for ion generation | Argon Gas |

| 3. Plasma Generation | Creates high-energy ions to bombard the target | High Voltage Power Supply |

| 4. Sputtering & Deposition | Ejects target atoms to form a thin film on the substrate | Target Material |

Need a high-purity, uniform coating for your application?

KINTEK specializes in precision lab equipment, including sputtering systems designed for R&D and production. Our solutions help you achieve the exact film properties—thickness, density, and adhesion—required for success in microelectronics, optics, and medical devices.

Contact our experts today to discuss how our sputtering technology can advance your project.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- What are the advantages of plasma enhanced CVD? Enable Low-Temperature, High-Quality Thin Film Deposition

- How are PECVD and CVD different? A Guide to Choosing the Right Thin-Film Deposition Process

- What is the difference between PECVD and sputter? Choose the Right Thin-Film Deposition Method

- What are the drawbacks of PECVD? Understanding the Trade-offs of Low-Temperature Deposition

- What is plasma activated chemical vapour deposition method? A Low-Temperature Solution for Advanced Coatings