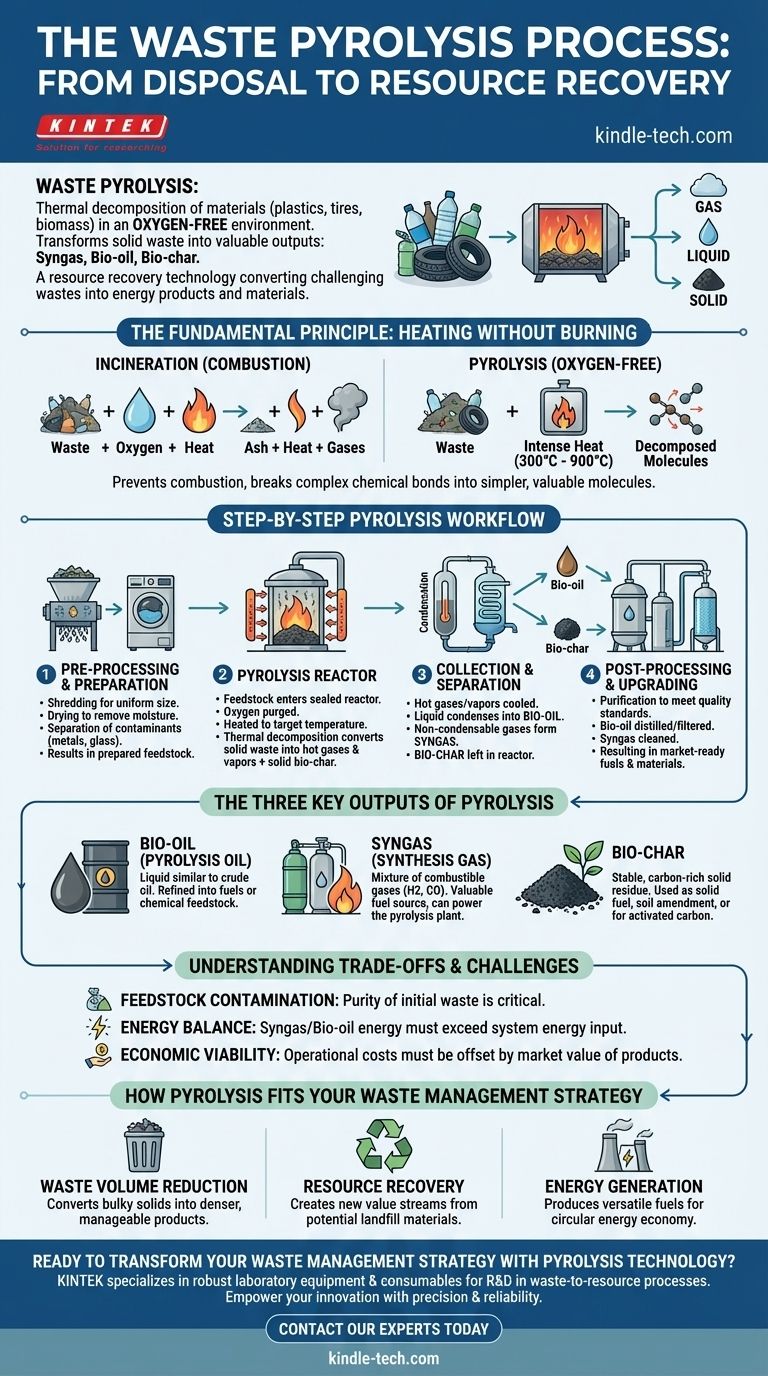

At its core, waste pyrolysis is a thermal decomposition process that breaks down materials like plastics, tires, or biomass by heating them in an oxygen-free environment. This controlled process transforms solid waste into valuable outputs: a synthetic gas (syngas), a liquid bio-oil, and a solid residue called bio-char.

Pyrolysis is not merely waste disposal; it is a resource recovery technology. It chemically converts challenging solid wastes into marketable energy products and materials, turning a liability into a potential asset.

The Fundamental Principle: Heating Without Burning

Pyrolysis is often confused with incineration, but they are fundamentally different processes driven by one key factor: the presence of oxygen.

What "Absence of Oxygen" Means

Incineration is combustion—it uses oxygen to burn waste, releasing heat and producing ash.

Pyrolysis, by contrast, prevents combustion by removing oxygen. Instead of burning, the intense heat breaks the complex chemical bonds within the waste material itself, decomposing it into simpler, more valuable molecules.

The Role of High Temperature

Heat is the catalyst for the entire process. By applying high temperatures (typically between 300°C and 900°C) inside a sealed reactor, the long polymer chains in plastics or the complex organic matter in biomass are broken down into the three distinct products.

A Step-by-Step Look at the Pyrolysis Workflow

While the specific equipment varies, the core process for converting solid waste follows a consistent and logical sequence.

Step 1: Pre-processing and Preparation

The raw waste material must be prepared. This usually involves shredding it into smaller, uniform pieces to increase surface area and ensure even heating.

The material is also dried to remove moisture and processed to separate any non-target contaminants (like metals or glass), ensuring a pure feedstock.

Step 2: The Pyrolysis Reactor

The prepared feedstock is fed into an airtight chamber called a pyrolysis reactor. Oxygen is purged from the system, and the material is heated to the target temperature.

It is inside this reactor that the thermal decomposition occurs, converting the solid waste into hot gases and vapors, leaving behind the solid bio-char.

Step 3: Collection and Separation of Products

The hot gases and vapors are channeled out of the reactor and into a condensing system.

As they cool, the liquid components condense into bio-oil, which is collected. The remaining non-condensable gases form the syngas, which is piped away.

Step 4: Post-processing and Upgrading

The raw outputs are often purified to meet specific quality standards. The bio-oil may be distilled or filtered to be used as a fuel, and the syngas may be cleaned before it is used.

The Three Key Outputs of Pyrolysis

The value of pyrolysis lies in its ability to create distinct and useful products from a single stream of waste.

Bio-oil (Pyrolysis Oil)

This is a liquid, similar in some ways to crude oil. It can be refined into various grades of fuel or used as a feedstock for the chemical industry.

Syngas (Synthesis Gas)

This mixture of combustible gases (primarily hydrogen and carbon monoxide) is a valuable fuel source. It is often used to power the pyrolysis plant itself, creating a self-sustaining energy loop.

Bio-char

This stable, carbon-rich solid residue is the final product. It can be used as a solid fuel, a soil amendment to improve agricultural land, or as the raw material for producing activated carbon for filtration.

Understanding the Trade-offs and Challenges

While promising, pyrolysis is a complex industrial process with practical considerations that determine its success.

Feedstock Contamination

The quality of the final products is highly dependent on the purity of the initial waste. Contaminants can lower the value of the bio-oil or damage the equipment, making the pre-processing step absolutely critical.

Energy Balance

A pyrolysis plant consumes a significant amount of energy to generate heat. For the process to be sustainable, the energy value of the syngas and bio-oil produced must be greater than the energy required to run the system.

Economic Viability

The ultimate challenge is economic. The operational costs, including waste collection, pre-processing, and energy input, must be offset by the market value of the bio-oil, syngas, and bio-char.

How Pyrolysis Fits Into Your Waste Management Strategy

The application of pyrolysis depends entirely on your end goal.

- If your primary focus is waste volume reduction: Pyrolysis is highly effective, converting bulky solid plastics and biomass into denser, more manageable, and valuable products.

- If your primary focus is resource recovery: The process excels at creating new value streams (fuel, chemicals, soil additives) from materials that would otherwise be landfilled.

- If your primary focus is energy generation: Pyrolysis offers a proven method to produce versatile fuels from non-traditional feedstocks, contributing to a more circular energy economy.

Ultimately, waste pyrolysis represents a critical shift from simple disposal to intelligent resource transformation.

Summary Table:

| Process Step | Key Action | Main Outputs |

|---|---|---|

| 1. Pre-processing | Shredding and drying waste | Prepared, uniform feedstock |

| 2. Pyrolysis Reactor | Heating in oxygen-free environment | Hot gases/vapors and solid bio-char |

| 3. Condensation | Cooling the hot vapors | Liquid bio-oil and syngas |

| 4. Post-processing | Purifying and upgrading outputs | Market-ready fuels and materials |

Ready to transform your waste management strategy with pyrolysis technology? KINTEK specializes in providing robust laboratory equipment and consumables to support your R&D in waste-to-resource processes. Whether you are developing a new pyrolysis application or optimizing an existing one, our products are designed for precision and reliability. Contact our experts today to discover how KINTEK can empower your laboratory's innovation in sustainable resource recovery.

Visual Guide

Related Products

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Powerful Plastic Crusher Machine

- Non Consumable Vacuum Arc Induction Melting Furnace

People Also Ask

- Why are sealed laboratory reaction vessels necessary in the hydrothermal synthesis of zeolites? Ensure Purity and Yield

- What is the contribution of a hydrothermal reactor to graded pore construction? Precision Templates for TAS

- What role does an autoclave play in simulating PWR conditions? Advanced Material Validation for Nuclear Safety

- What is the role of high-pressure reactors in the study of alloy oxidation? Essential Tools for Supercritical Research

- What is the function of a constant temperature hydrothermal reactor? Master Coal Fly Ash Activation