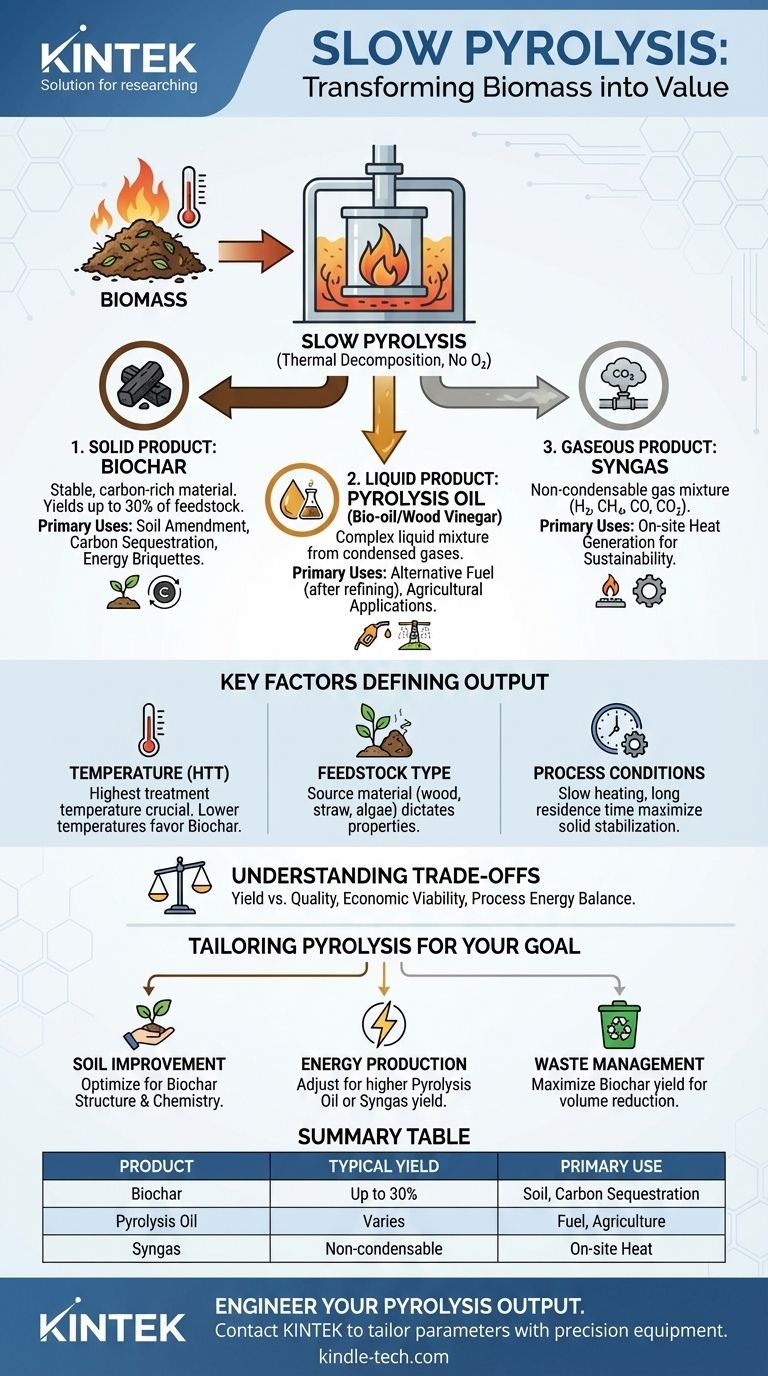

In short, slow pyrolysis is a thermal decomposition process that breaks down biomass in the absence of oxygen, yielding three primary products. These are a solid carbon-rich material called biochar, a liquid fraction known as pyrolysis oil or wood vinegar, and a non-condensable syngas. The main goal of slow pyrolysis is typically to maximize the production of the solid biochar.

Slow pyrolysis is best understood not as a single outcome, but as a tunable process. The specific yields and characteristics of the solid, liquid, and gas products are deliberately controlled by adjusting process parameters to create a "tailor-made" output for a specific application, such as soil improvement or energy generation.

Understanding the Core Products of Slow Pyrolysis

Slow pyrolysis separates biomass into stable and usable components. Each of the three product streams—solid, liquid, and gas—has distinct properties and applications.

The Solid Product: Biochar

Biochar (also referred to as char, biocoal, or coke) is the primary solid product, and its production is often the main objective of slow pyrolysis. It is a stable, carbon-rich material that resembles charcoal.

Under typical slow pyrolysis conditions, biochar yields can be up to 30% of the initial dry feedstock weight.

Its primary uses are in agriculture as a soil amendment to improve fertility and as a method for long-term carbon sequestration. It is also used to create energy briquettes or as an industrial sorbent.

The Liquid Product: Pyrolysis Oil (Bio-oil)

As the pyrolysis gases cool, a portion condenses into a complex liquid mixture. This is known as pyrolysis oil, bio-oil, or, in some contexts, wood vinegar.

This liquid can be used as an alternative fuel, sometimes after being refined into products like biodiesel. The aqueous fraction, or wood vinegar, has applications in agriculture.

The Gaseous Product: Syngas

The components that do not condense into liquid form a mixture of non-condensable gases, often called synthesis gas or syngas.

This gas stream consists of hydrogen (H₂), methane (CH₄), carbon monoxide (CO), carbon dioxide (CO₂), and various other hydrocarbons.

In most pyrolysis plants, this syngas is not sold but is consumed on-site to generate the heat required to sustain the pyrolysis process, making the system more energy-efficient.

Key Factors That Define the Output

You cannot view the products of pyrolysis as fixed. They are the direct result of controlled variables, allowing operators to engineer the output for a specific purpose.

The Critical Role of Temperature

The highest treatment temperature (HTT) is the single most influential factor affecting the final characteristics of the products.

Slow pyrolysis intentionally uses lower temperatures and slower heating rates to favor the chemical reactions that produce solid biochar over those that produce liquids and gases.

The Influence of Feedstock

The process begins with biomass, and the type of feedstock directly shapes the outcome. Materials like pine wood, wheat straw, green waste, or even dried algae will each produce biochar with different physicochemical properties.

This is why producing a "tailor-made" biochar for a specific soil type requires careful selection of the input material.

Process Conditions: Heating Rate & Residence Time

The "slow" in slow pyrolysis refers to a slow heating rate and a long vapor residence time.

These conditions ensure that the biomass is thoroughly converted and that secondary reactions occur, which stabilizes the carbon in the solid biochar structure rather than breaking it down further into liquids and gases.

Understanding the Trade-offs

Optimizing for one product or characteristic often comes at the expense of another. Understanding these compromises is key to any practical application.

Yield vs. Quality

The conditions that maximize the sheer volume (yield) of biochar may not produce biochar with the ideal properties for a given application. For example, a high-yield char might lack the porosity needed for effective soil amendment.

Economic Viability

The high degree of variability in products makes it difficult to establish a standardized market price. The economic success of a pyrolysis operation depends on finding a consistent, high-value application for its specific outputs.

Process Energy Balance

While syngas is a valuable energy product, it is frequently needed to power the pyrolysis reactor itself. This creates an internal energy loop, meaning the gas is often an operational input rather than a sellable output.

Tailoring Pyrolysis for Your Goal

The right approach depends entirely on your primary objective. By controlling the inputs and process conditions, you can steer the output to meet your specific needs.

- If your primary focus is soil improvement: Prioritize the selection of feedstock and a specific temperature profile to produce "tailor-made" biochar with the optimal structure and chemical properties for enhancing soil fertility and carbon storage.

- If your primary focus is energy production: Adjust parameters like temperature and heating rate to increase the yield of pyrolysis oil or syngas, which can be used as fuel. This often means sacrificing maximum biochar yield.

- If your primary focus is waste management: Optimize for maximizing the solid biochar yield, as this converts a large volume of biomass waste into a stable, dense, and manageable solid product.

Ultimately, slow pyrolysis is a versatile conversion technology that transforms biomass into a spectrum of valuable products by deliberate and controlled engineering.

Summary Table:

| Product | Typical Yield | Primary Use |

|---|---|---|

| Biochar (Solid) | Up to 30% of feedstock | Soil amendment, carbon sequestration |

| Pyrolysis Oil (Liquid) | Varies with conditions | Alternative fuel, agricultural use |

| Syngas (Gas) | Non-condensable portion | On-site heat for process sustainability |

Ready to Engineer Your Pyrolysis Output?

Whether your goal is to produce high-quality biochar for agriculture, optimize liquid fuels, or manage biomass waste efficiently, KINTEK's expertise in thermal processing equipment can help you achieve it. Our lab systems are ideal for testing and tailoring pyrolysis parameters to your specific biomass and objectives.

Contact our experts today to discuss how we can support your pyrolysis project with precision equipment and consumables.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- High Pressure Laboratory Autoclave Reactor for Hydrothermal Synthesis

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- Lab-Scale Vacuum Induction Melting Furnace

- Stainless High Pressure Autoclave Reactor Laboratory Pressure Reactor

People Also Ask

- What is a disadvantage of biomass energy? The Hidden Environmental and Economic Costs

- What are the components of biomass pyrolysis? A Complete Guide to the System, Products, and Process

- What are the different types of pyrolysis machines? Choose the Right System for Your Output

- What are the conditions for biomass pyrolysis? Optimize Temperature, Heating Rate & Time

- How is energy converted into biomass? Harnessing Nature's Solar Power for Renewable Energy