At its core, the production of steel by Electric Arc Furnace (EAF) is a process that uses a high-power electric arc to melt recycled steel scrap and other metallic inputs. This intense heat, generated between graphite electrodes and the metal, transforms the solid materials into liquid steel, which can then be refined and cast into new products. This method has become the dominant form of steelmaking in the United States, accounting for over 70% of the country's total production.

The Electric Arc Furnace represents a fundamental shift in steelmaking. It moves production away from a reliance on raw iron ore and towards a more flexible, efficient, and recycling-centric model powered by electricity.

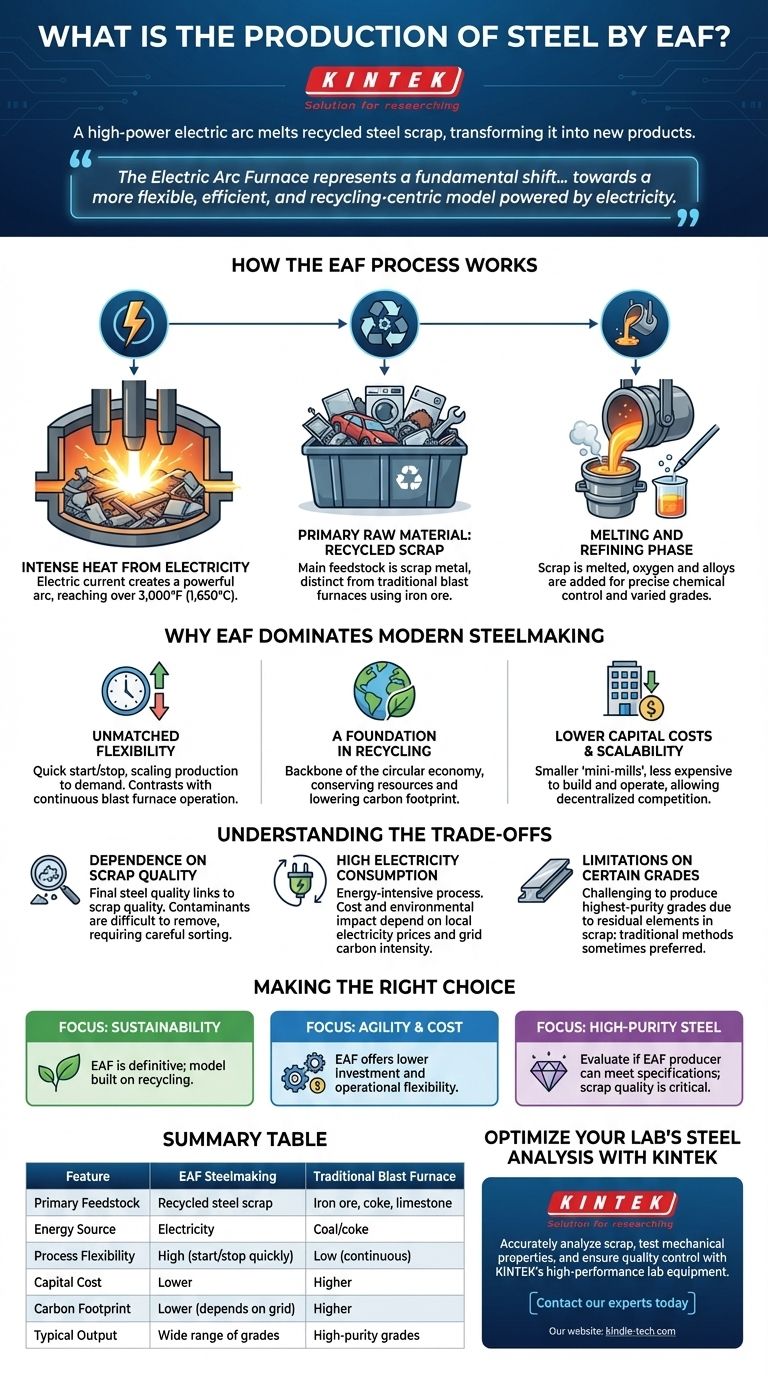

How the EAF Process Works

To understand why the EAF method is so prevalent, you must first grasp its core mechanics. The process is defined by its direct application of electrical energy to melt metal.

The Core Principle: Intense Heat from Electricity

An EAF operates much like a controlled, man-made lightning strike. Large graphite electrodes are lowered into a furnace filled with scrap metal. A massive electric current is passed through these electrodes, creating a powerful arc that strikes the metal. This arc generates immense heat, with temperatures capable of reaching over 3,000°F (1,650°C), rapidly melting the charge.

The Primary Raw Material: Recycled Scrap

Unlike traditional blast furnaces that make steel from iron ore, the primary feedstock for an EAF is scrap metal. This can include everything from end-of-life automobiles and appliances to industrial scrap from manufacturing processes. This reliance on recycling is a defining characteristic of EAF steelmaking.

The Melting and Refining Phase

Once the scrap is melted into a liquid bath, the refining process begins. Oxygen is often injected to remove impurities like carbon, and other alloys are added to the molten steel. This allows producers to precisely control the chemistry and create a wide variety of steel grades, from simple construction rebar to more specialized products.

Why EAF Dominates Modern Steelmaking

The shift to EAF production isn't accidental; it is driven by significant economic and operational advantages over older, more integrated steelmaking methods.

Unmatched Production Flexibility

EAFs can be started and stopped relatively quickly, often within a few hours. This allows steelmakers to operate with incredible agility, scaling production up or down to match real-time market demand. This stands in stark contrast to traditional blast furnaces, which must run continuously for months or even years at a time.

A Foundation in Recycling

By using scrap as its main input, the EAF process forms the backbone of the circular economy for steel. It reduces the need for virgin materials, conserves natural resources, and significantly lowers the overall carbon footprint compared to ore-based production.

Lower Capital Costs and Scalability

EAF facilities, often called "mini-mills," are typically smaller and significantly less expensive to build and operate than the massive integrated mills required for traditional steelmaking. This lower barrier to entry has allowed for a more decentralized and competitive industry landscape.

Understanding the Trade-offs

While the EAF process is highly advantageous, it is not without its own set of specific challenges and limitations. Acknowledging these trade-offs is key to a complete understanding.

Dependence on Scrap Quality

The quality of the final steel is directly linked to the quality of the incoming scrap. Contaminants in the scrap, such as copper or tin, can be difficult to remove and may impact the properties of the finished steel. This necessitates careful sorting and inspection of raw materials.

High Electricity Consumption

As the name implies, the process is electricity-intensive. This makes production costs sensitive to fluctuations in local electricity prices. Furthermore, the environmental benefit of EAF steel is tied to the carbon intensity of the power grid it draws from; its green credentials are strongest when powered by renewable energy sources.

Limitations on Certain Steel Grades

While highly flexible, producing the absolute highest-purity steel grades can be challenging in an EAF due to residual elements inherited from the scrap. For certain demanding applications, such as the exposed body panels on automobiles, steel from traditional ore-based methods is sometimes still preferred.

Making the Right Choice for Your Goal

Your perspective on EAF steelmaking will depend entirely on your strategic objectives.

- If your primary focus is sustainability and resource efficiency: The EAF method is the definitive choice, as its entire model is built upon recycling steel.

- If your primary focus is production agility and cost-effectiveness: EAFs offer a lower initial investment and the operational flexibility needed to navigate volatile market conditions.

- If your primary focus is sourcing high-purity specialty steel: You must evaluate whether an EAF producer can meet your specifications, as the quality of their scrap feedstock is a critical factor.

Ultimately, understanding the principles of EAF steelmaking empowers you to make more informed decisions in sourcing, investment, and strategic planning.

Summary Table:

| Feature | EAF Steelmaking | Traditional Blast Furnace |

|---|---|---|

| Primary Feedstock | Recycled steel scrap | Iron ore, coke, limestone |

| Energy Source | Electricity | Coal/coke |

| Process Flexibility | High (can start/stop quickly) | Low (continuous operation) |

| Capital Cost | Lower | Higher |

| Carbon Footprint | Lower (depends on grid) | Higher |

| Typical Output | Wide range of steel grades | High-purity steel grades |

Optimize Your Lab's Steel Analysis with KINTEK

Whether you're researching EAF steel properties, testing scrap quality, or developing new alloys, having the right lab equipment is crucial. KINTEK specializes in high-performance laboratory equipment and consumables for metallurgical analysis, including spectrometers, sample preparation tools, and furnace systems.

Our solutions help you:

- Accurately analyze scrap metal composition

- Test the mechanical properties of EAF-produced steel

- Ensure quality control throughout the steelmaking process

Contact our experts today to discuss how KINTEK can support your laboratory's specific needs in steel research and production.

Visual Guide

Related Products

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vertical Laboratory Tube Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vacuum Induction Melting Spinning System Arc Melting Furnace

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

People Also Ask

- How do you clean a tube furnace tube? A Step-by-Step Guide to Safe and Effective Cleaning

- What tube is used for tubular furnace? Choose the Right Material for Temperature & Atmosphere

- What are the advantages of using an alumina liner in a tube furnace for biomass combustion corrosion simulations?

- What are the common applications for a tube furnace? Essential for Heat Treatment, Synthesis, and Purification

- What is the pressure on a tube furnace? Essential Safety Limits for Your Lab