In short, Physical Vapor Deposition (PVD) is a sophisticated vacuum coating process used to apply extremely thin yet highly durable films onto a wide variety of materials. The purpose of this process is to fundamentally enhance the surface properties of an object—improving its hardness, wear resistance, and longevity, or giving it a specific color or optical quality, all without changing the underlying material's core structure.

The central purpose of PVD is not merely to coat an object, but to engineer its surface at a molecular level. It transforms a standard material into a high-performance version by bonding a superior thin film to it.

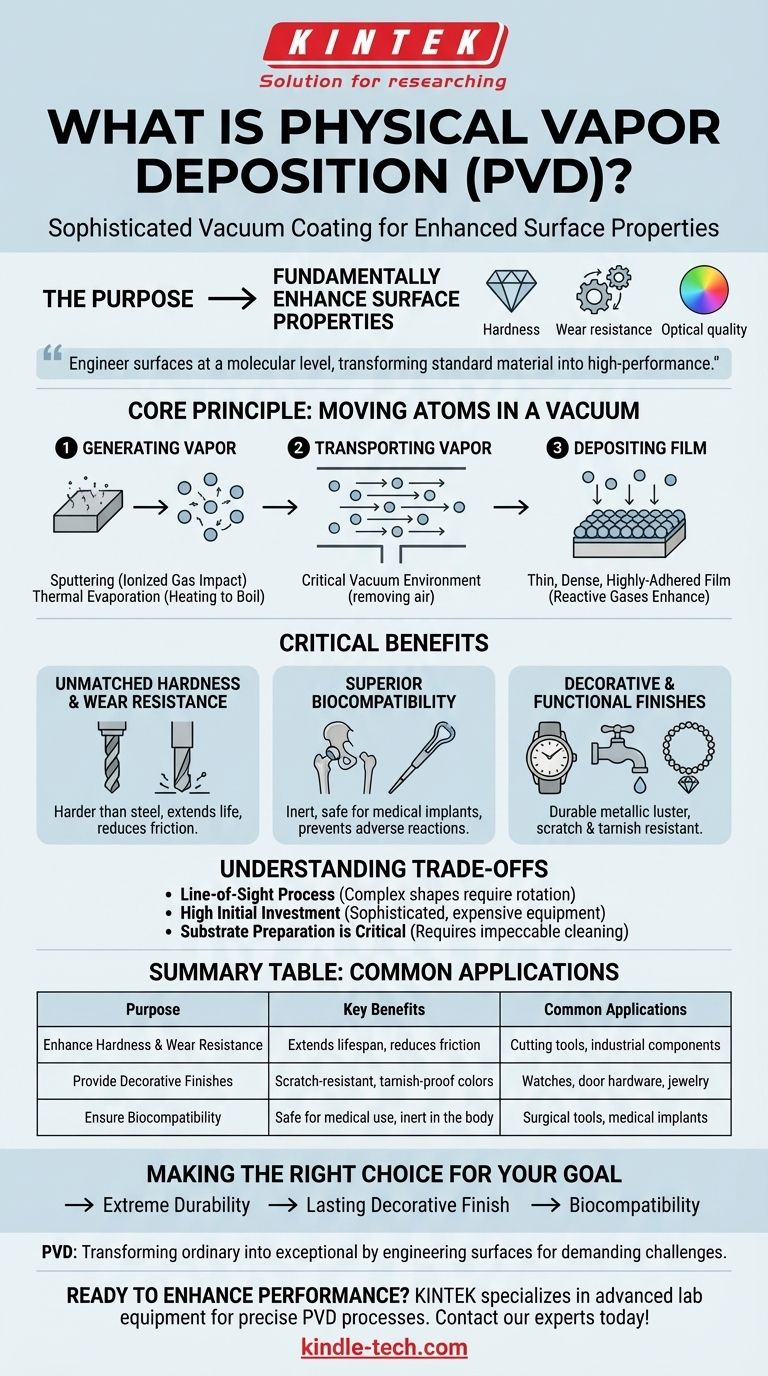

The Core Principle: Moving Atoms in a Vacuum

Physical Vapor Deposition describes a family of processes, but they all share a common, three-step principle that takes place inside a high-vacuum chamber.

Step 1: Generating a Vapor

First, a solid source material—often a metal like titanium, chromium, or zirconium—must be converted into a vapor. This is the "Physical Vapor" part of the name. This is typically achieved through one of two primary methods:

- Sputtering: In this method, the target material is bombarded with high-energy ionized gas particles (like argon). This impact is like a molecular-scale sandblasting, knocking atoms loose from the source material and ejecting them into the vacuum chamber.

- Thermal Evaporation: This method involves heating the source material until it literally boils and evaporates, releasing atoms in vapor form.

Step 2: Transporting the Vapor

Once the atoms are freed from their source, they travel through the vacuum chamber. The vacuum is critical because it removes air and other particles, ensuring the vaporized atoms can travel in a straight line without colliding with anything until they reach their destination.

Step 3: Depositing the Film

The vaporized atoms arrive at the surface of the object being coated (the "substrate"). They condense onto this surface, building up layer by layer to form a thin, dense, and highly-adhered film. Often, a reactive gas like nitrogen or carbon is introduced to create specific compounds like titanium nitride, further enhancing the film's properties.

Why PVD is a Critical Manufacturing Process

The true purpose of PVD lies in the powerful benefits it delivers. The resulting coatings are not like paint; they are atomically bonded to the substrate, making them exceptionally durable.

Unmatched Hardness and Wear Resistance

PVD coatings, such as titanium nitride (TiN), are often harder than steel. This makes them ideal for protecting cutting tools, drills, and industrial components from the friction and abrasion of daily use, dramatically extending their operational life.

Superior Biocompatibility

Certain PVD coatings are inert and biocompatible, meaning they do not react with the human body. This makes PVD an essential process for coating medical implants like artificial joints and surgical instruments, preventing adverse reactions and improving durability.

Decorative and Functional Finishes

PVD allows for the deposition of a wide range of colors with a metallic luster that is far more durable than traditional plating. This is why it's used on high-end watches, faucets, and door hardware to create finishes that resist scratches and tarnishing for years.

Understanding the Trade-offs

While powerful, PVD is not a universal solution. Understanding its limitations is key to using it effectively.

It is a Line-of-Sight Process

Because the vapor atoms travel in a straight line, it can be challenging to evenly coat complex shapes with deep recesses or internal surfaces. Parts often need to be rotated on complex fixtures to ensure uniform coverage.

High Initial Investment

PVD equipment is sophisticated and expensive. It requires a vacuum chamber, high-power sources, and precise process controls, making the initial capital cost significant. This is why it is typically used for high-value or high-performance applications.

Substrate Preparation is Critical

The success of PVD coating is heavily dependent on the cleanliness of the substrate. The surface must be impeccably clean—free of oils, oxides, and any other contaminants—to ensure the film adheres properly. This often requires extensive multi-step cleaning processes before the part ever enters the coater.

Making the Right Choice for Your Goal

PVD is chosen when surface performance is a non-negotiable requirement. The decision to use it depends entirely on the desired outcome for your part or product.

- If your primary focus is extreme durability: PVD is the definitive choice for creating a hard, wear-resistant surface on cutting tools, molds, and mechanical components to maximize their lifespan.

- If your primary focus is a lasting decorative finish: PVD provides a far more robust and tarnish-resistant alternative to traditional electroplating for consumer products like watches, jewelry, or premium hardware.

- If your primary focus is biocompatibility: For medical implants and surgical tools, PVD is a critical process to ensure the device is safe, inert, and durable inside the human body.

Ultimately, PVD is a tool for transforming the ordinary into the exceptional by engineering a surface to meet the most demanding challenges.

Summary Table:

| Purpose of PVD Coating | Key Benefits | Common Applications |

|---|---|---|

| Enhance Hardness & Wear Resistance | Extends product lifespan, reduces friction | Cutting tools, industrial components |

| Provide Decorative Finishes | Scratch-resistant, tarnish-proof colors | Watches, door hardware, jewelry |

| Ensure Biocompatibility | Safe for medical use, inert in the body | Surgical tools, medical implants |

Ready to enhance your product's performance with a durable PVD coating? KINTEK specializes in advanced lab equipment and consumables for precise PVD processes. Our solutions help you achieve superior surface engineering for longer-lasting, higher-performance parts. Contact our experts today to discuss how we can support your laboratory's coating needs!

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

People Also Ask

- Why is a Matching Network Indispensable in RF-PECVD for Siloxane Films? Ensure Stable Plasma and Uniform Deposition

- What are the process capabilities of ICPCVD systems? Achieve Low-Damage Film Deposition at Ultra-Low Temperatures

- What is the process of PECVD in semiconductor? Enabling Low-Temperature Thin Film Deposition

- What is the difference between plasma CVD and thermal CVD? Choose the Right Method for Your Substrate

- How are thin films deposited? A Guide to PVD vs. CVD Methods for Your Application