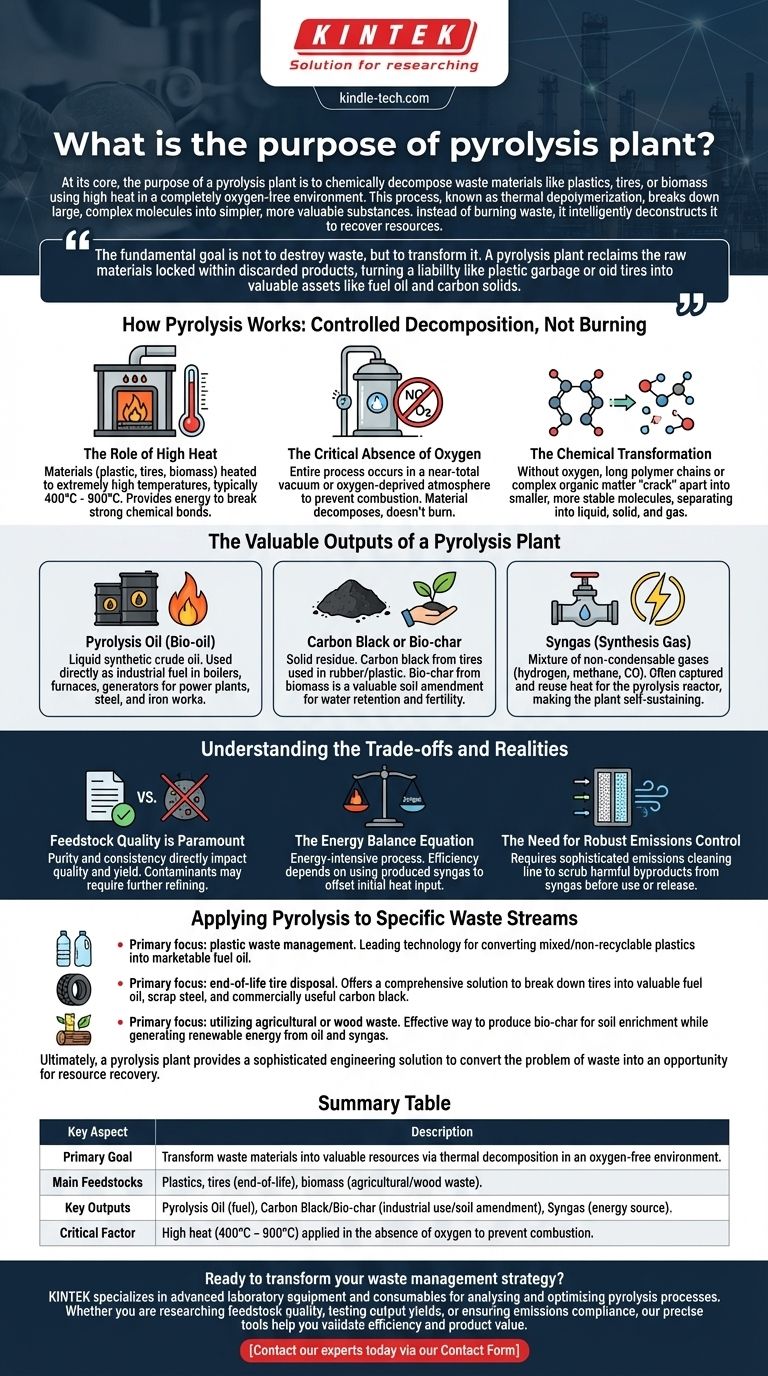

At its core, the purpose of a pyrolysis plant is to chemically decompose waste materials like plastics, tires, or biomass using high heat in a completely oxygen-free environment. This process, known as thermal depolymerization, breaks down large, complex molecules into simpler, more valuable substances. Instead of burning waste, it intelligently deconstructs it to recover resources.

The fundamental goal is not to destroy waste, but to transform it. A pyrolysis plant reclaims the raw materials locked within discarded products, turning a liability like plastic garbage or old tires into valuable assets like fuel oil and carbon solids.

How Pyrolysis Works: Controlled Decomposition, Not Burning

Pyrolysis is a thermochemical process that is fundamentally different from incineration (burning). The key distinction lies in the controlled environment, specifically the absence of oxygen.

The Role of High Heat

Materials like plastic or biomass are fed into a sealed reactor. Inside, they are heated to extremely high temperatures, typically between 400°C and 900°C (750°F to 1650°F). This intense heat provides the energy needed to break the strong chemical bonds holding the large molecules together.

The Critical Absence of Oxygen

This entire process occurs in a near-total vacuum or an oxygen-deprived atmosphere. Preventing oxygen from entering the reactor is crucial because it stops combustion from occurring. The material doesn't burn; it simply decomposes under thermal stress.

The Chemical Transformation

Without oxygen to react with, the long polymer chains in plastics or the complex organic matter in biomass "crack" apart into smaller, more stable molecules. This results in the separation of the original material into three distinct forms: a liquid, a solid, and a gas.

The Valuable Outputs of a Pyrolysis Plant

The output of a pyrolysis plant depends on the initial feedstock, but the products generally fall into three main categories, each with its own industrial use.

Pyrolysis Oil (Bio-oil)

This liquid product is a type of synthetic crude oil. It can be used directly as an industrial fuel in boilers, furnaces, or generators to produce electricity. It serves industries such as steel and iron works, ceramics factories, and power plants.

Carbon Black or Bio-char

The solid residue left after pyrolysis is a form of carbon. When the feedstock is old tires, this product is called carbon black, which can be used as a pigment or reinforcing agent in the rubber and plastic industries. When the feedstock is biomass (like wood or crop waste), it is called bio-char, a valuable soil amendment that improves water retention and fertility.

Syngas (Synthesis Gas)

The process also produces a mixture of non-condensable gases, primarily hydrogen, methane, and carbon monoxide. This syngas is combustible and is often captured and reused on-site to provide the heat needed to run the pyrolysis reactor, making the plant more energy-efficient and self-sustaining.

Understanding the Trade-offs and Realities

While a powerful technology, pyrolysis is not a magic bullet. Its successful implementation depends on several key factors and presents certain challenges.

Feedstock Quality is Paramount

The purity and consistency of the input material directly impact the quality and yield of the final products. Contaminated plastic waste, for example, can introduce impurities into the pyrolysis oil, requiring further refining.

The Energy Balance Equation

Pyrolysis is an energy-intensive process requiring a significant initial heat input. The overall efficiency and economic viability of a plant often depend on its ability to use the produced syngas to offset its own energy consumption.

The Need for Robust Emissions Control

Although pyrolysis avoids the large-scale creation of dioxins and furans associated with incineration, it can still release volatile compounds. A modern pyrolysis plant requires a sophisticated emissions cleaning line to scrub and filter any harmful byproducts from the syngas before it is used or released.

Applying Pyrolysis to Specific Waste Streams

Your choice to consider pyrolysis should align directly with the type of waste you need to manage and the end products you wish to create.

- If your primary focus is plastic waste management: Pyrolysis is a leading technology for converting mixed or non-recyclable plastics into a marketable fuel oil.

- If your primary focus is end-of-life tire disposal: This process offers a comprehensive solution, breaking tires down into valuable fuel oil, scrap steel, and commercially useful carbon black.

- If your primary focus is utilizing agricultural or wood waste: Biomass pyrolysis is an effective way to produce bio-char for soil enrichment while simultaneously generating renewable energy from the oil and syngas.

Ultimately, a pyrolysis plant provides a sophisticated engineering solution to convert the problem of waste into an opportunity for resource recovery.

Summary Table:

| Key Aspect | Description |

|---|---|

| Primary Goal | Transform waste materials into valuable resources via thermal decomposition in an oxygen-free environment. |

| Main Feedstocks | Plastics, tires (end-of-life), biomass (agricultural/wood waste). |

| Key Outputs | Pyrolysis Oil (fuel), Carbon Black/Bio-char (industrial use/soil amendment), Syngas (energy source). |

| Critical Factor | High heat (400°C - 900°C) applied in the absence of oxygen to prevent combustion. |

Ready to transform your waste management strategy?

KINTEK specializes in advanced laboratory equipment and consumables for analyzing and optimizing pyrolysis processes. Whether you are researching feedstock quality, testing output yields, or ensuring emissions compliance, our precise tools help you validate efficiency and product value.

Contact our experts today via our Contact Form to discuss how our solutions can support your journey in resource recovery and sustainable waste transformation.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- High Pressure Laboratory Autoclave Reactor for Hydrothermal Synthesis

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

People Also Ask

- What are the products of pyrolysis of biomass? Unlock Bio-Char, Bio-Oil, and Syngas

- Is pyrolysis viable? A Guide to Economic, Technological, and Environmental Success

- What is the process of biomass fast pyrolysis? Turn Biomass into Bio-Oil in Seconds

- What are the components of biomass pyrolysis? A Complete Guide to the System, Products, and Process

- What is a disadvantage of biomass energy? The Hidden Environmental and Economic Costs