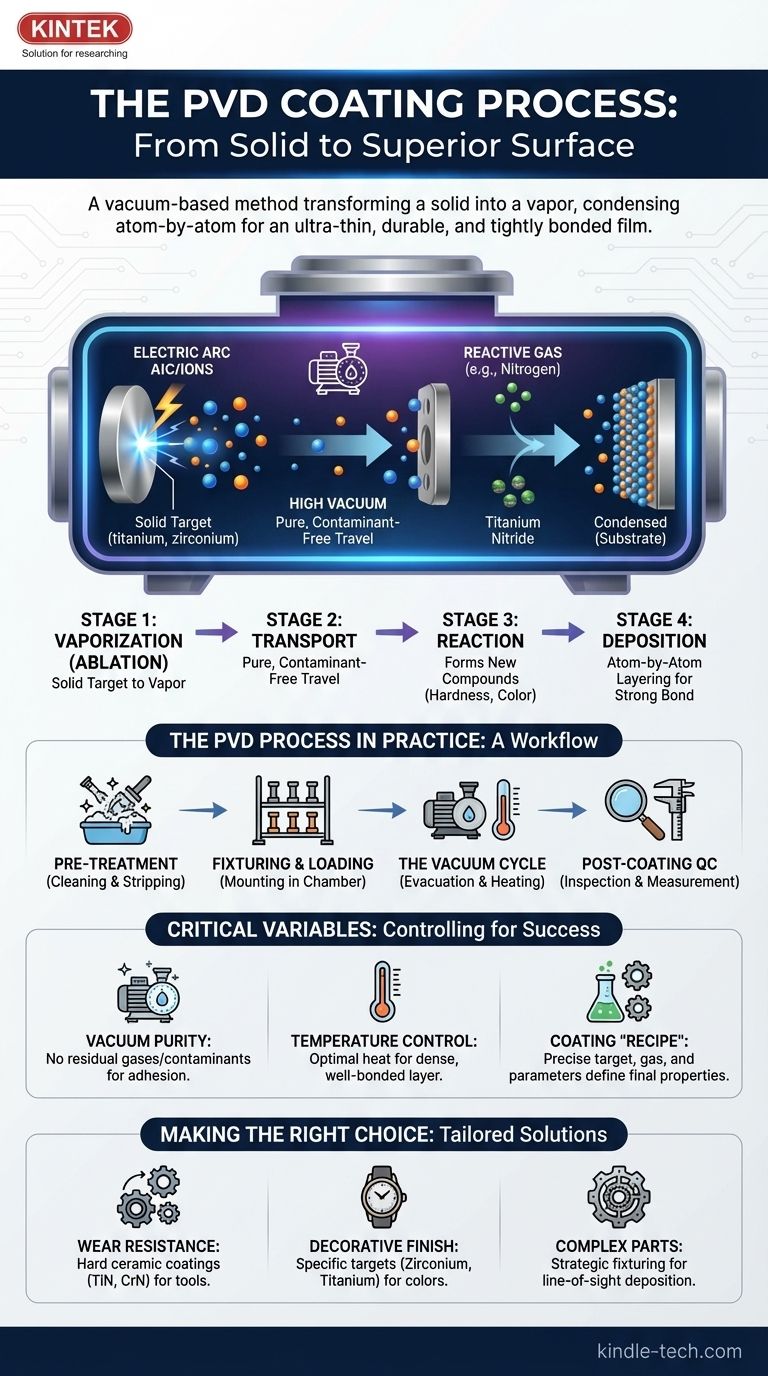

At its core, the Physical Vapor Deposition (PVD) process is a vacuum-based coating method that transforms a solid material into a vapor, which then condenses atom-by-atom onto a target object's surface. This creates an extremely thin, durable, and tightly bonded film. Unlike painting or plating, PVD forms a metal or metal-ceramic layer that fundamentally alters the surface properties of the component.

The crucial takeaway is that PVD is not simply a surface layer; it's a sophisticated, atom-level construction process. By precisely controlling a high-vacuum environment, you can build a new surface on a component, engineered for superior hardness, corrosion resistance, or specific aesthetic qualities.

The Four Foundational Stages of PVD

To truly understand PVD, you must see it as a sequence of four distinct physical events that occur within the vacuum chamber.

Stage 1: Vaporization (Ablation)

This is the starting point, where a solid source material, known as a target, is converted into a gaseous vapor.

Targets are often pure metals like titanium, zirconium, or chromium. The method of vaporization is a key differentiator, with common techniques including cathodic arc (using an electric arc to vaporize the target) or sputtering (bombarding the target with ions).

Stage 2: Transport

Once vaporized, the cloud of atoms and ions travels from the target toward the components being coated.

This journey must occur in a high vacuum. The vacuum removes air and other particles, ensuring the vaporized atoms don't collide with contaminants, which would disrupt the process and compromise the coating's purity and adhesion.

Stage 3: Reaction

For many advanced coatings, this is where the material's final properties are defined.

A reactive gas, such as nitrogen or a carbon-based gas, is precisely introduced into the chamber. The vaporized metal atoms react with this gas mid-flight, forming new compounds (e.g., titanium atoms react with nitrogen to form titanium nitride), which determines the final coating's hardness, color, and chemical resistance.

Stage 4: Deposition

In the final stage, the vaporized material condenses onto the surfaces of the components, or substrates.

This deposition occurs atom by atom, forming a thin, dense, and highly uniform film. The strong bond created between the coating and the substrate is a direct result of this atomic-level layering process.

The PVD Process in Practice

While the four physical stages happen inside the chamber, a successful PVD coating application involves a much broader, multi-step workflow.

Pre-Treatment and Cleaning

The final coating is only as good as the surface it's applied to. Parts must be meticulously cleaned to remove any oils, dirt, or oxides. In some cases, previous coatings may need to be chemically stripped away.

Fixturing and Loading

Components are carefully mounted on specialized racks or fixtures inside the vacuum chamber. Proper fixturing is essential to ensure all critical surfaces are exposed to the vaporized material for a uniform coating.

The Vacuum Cycle

The chamber is sealed, and powerful pumps evacuate the air to create the necessary high-vacuum environment, often reaching pressures millions of times lower than the atmosphere. The parts are then heated to a specific process temperature to further clean the surfaces and promote better coating adhesion.

Post-Coating Quality Control

After the cycle is complete, the parts are inspected. This often includes visual checks for cosmetic consistency and technical measurements of the coating's thickness to ensure it meets specifications.

Understanding the Critical Variables

The success of PVD coating hinges on the precise control of several key factors. Mismanagement of these variables is the most common source of failure.

Vacuum Purity

The quality of the vacuum is non-negotiable. Any residual gases, water vapor, or contaminants will be incorporated into the coating, leading to poor adhesion, discoloration, or structural defects.

Temperature Control

The temperature of the substrate during the process directly impacts the coating's structure and its adhesion. The optimal temperature ensures the deposited atoms have enough energy to form a dense, well-bonded layer without damaging the substrate itself.

The Coating "Recipe"

The final outcome is dictated by the precise recipe used. The choice of target material, the type and flow rate of the reactive gas, and the electrical parameters used for vaporization all work together to define the coating's final color, hardness, and performance characteristics.

Making the Right Choice for Your Goal

PVD is not a one-size-fits-all solution; the process is tailored to achieve a specific outcome.

- If your primary focus is extreme wear resistance: You will need a hard ceramic coating like Titanium Nitride (TiN) or Chromium Nitride (CrN), requiring precise control over the nitrogen reactive gas and deposition temperature.

- If your primary focus is a specific decorative finish: The choice of target material (like Zirconium for a brass color or Titanium for gold/rose gold) and the exact gas mixture are the most critical factors for achieving consistent color.

- If you are coating complex parts with deep recesses: The fixturing strategy and part rotation within the chamber are paramount to ensure the line-of-sight deposition process reaches all necessary surfaces.

Ultimately, understanding the PVD process is about controlling a precise, atomic-level construction to build a fundamentally better surface.

Summary Table:

| Stage | Key Action | Outcome |

|---|---|---|

| 1. Vaporization | Solid target material is vaporized. | Creates a cloud of metal atoms/ions. |

| 2. Transport | Vapor travels through a high vacuum. | Ensures pure, uncontaminated material flow. |

| 3. Reaction | Vapor reacts with gases (e.g., Nitrogen). | Defines final coating properties (hardness, color). |

| 4. Deposition | Atoms condense onto the substrate surface. | Forms a thin, dense, and highly adherent film. |

Ready to engineer superior surfaces with PVD coating?

At KINTEK, we specialize in providing the advanced lab equipment and consumables needed to master the PVD process. Whether your goal is extreme wear resistance for cutting tools, a specific decorative finish for consumer goods, or a corrosion-resistant layer for medical components, our expertise ensures you achieve precise, high-quality results.

We help you:

- Select the right materials (targets, gases) for your application.

- Optimize process parameters (temperature, vacuum) for perfect adhesion and performance.

- Scale your operations with reliable, high-performance coating systems.

Let's build a better surface, together. Contact our experts today to discuss your project needs.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- Molybdenum Tungsten Tantalum Special Shape Evaporation Boat

People Also Ask

- How are PECVD and CVD different? A Guide to Choosing the Right Thin-Film Deposition Process

- What are the applications of PECVD? Essential for Semiconductors, MEMS, and Solar Cells

- Why does PECVD commonly use RF power input? For Precise Low-Temperature Thin Film Deposition

- What are the advantages of PECVD? Enable Low-Temperature, High-Quality Thin-Film Deposition

- What is plasma activated chemical vapour deposition method? A Low-Temperature Solution for Advanced Coatings