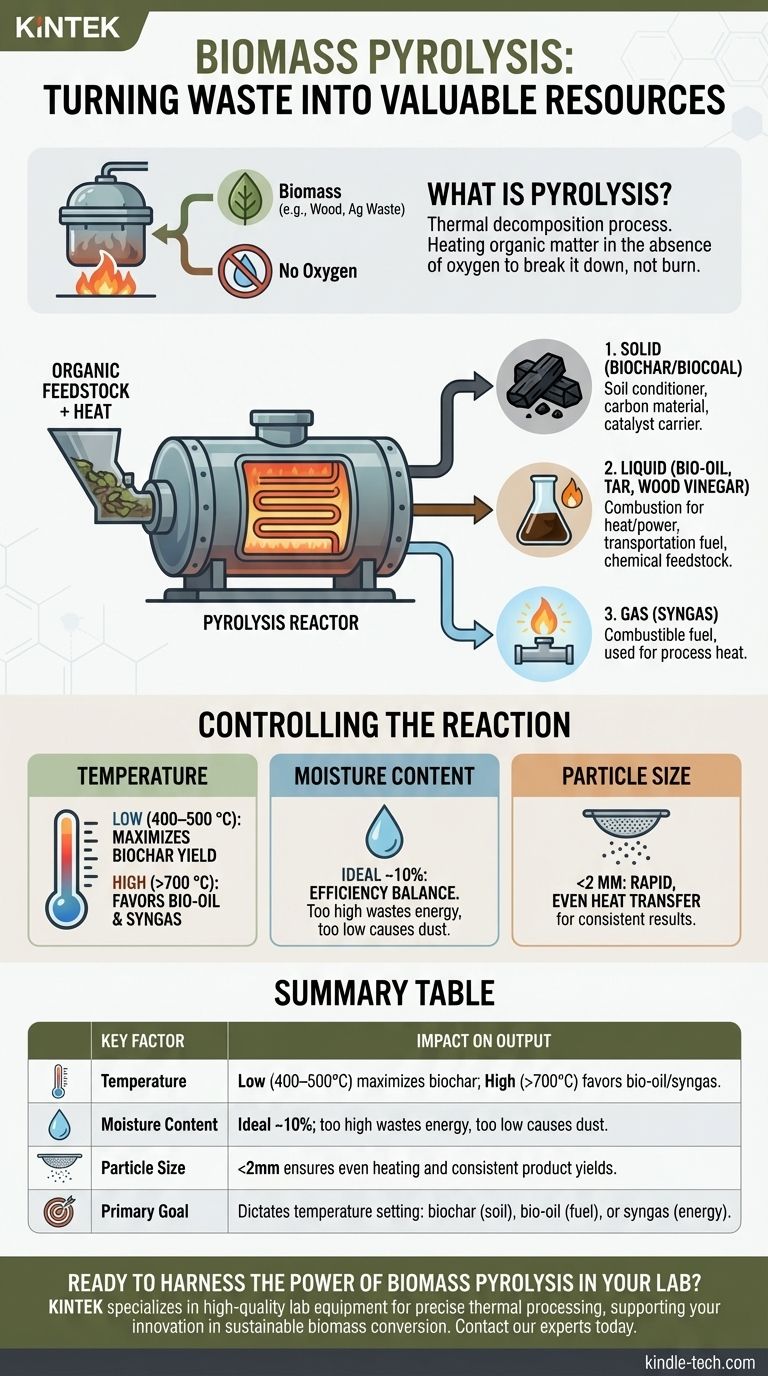

In essence, the pyrolysis of biomass is a thermal decomposition process. It involves heating organic matter, such as wood or agricultural waste, to high temperatures in the complete absence of oxygen, which prevents it from burning and instead chemically breaks it down into a solid, a liquid, and a gas.

Biomass pyrolysis is not a single, fixed reaction but a highly controlled thermal process. The core principle is that you can manipulate conditions like temperature and feedstock properties to deliberately favor the production of either solid biochar, liquid bio-oil, or combustible syngas.

The Fundamental Process: Deconstructing Biomass

What is Pyrolysis?

Pyrolysis is a chemical reaction driven solely by heat. By eliminating oxygen from the reaction chamber, you prevent combustion (burning).

Instead of turning to ash and smoke, the complex organic molecules within the biomass break apart into simpler, smaller molecules, which then re-form as new products.

The Key Inputs

The process requires two primary inputs: an organic feedstock (the biomass itself) and heat to drive the reaction. The exact composition of the feedstock will influence the final product mix.

The Three Primary Outputs

The reaction transforms the solid biomass into three distinct product categories.

- Solid: A carbon-rich solid residue known as biochar or biocoal.

- Liquid: A complex liquid mixture often called bio-oil or pyrolysis oil. This can also include separate fractions like tar and wood vinegar.

- Gas: A blend of non-condensable gases, such as syngas, which is combustible.

Controlling the Reaction to Define the Output

The specific yields of biochar, bio-oil, and syngas are not random. They are a direct result of the process conditions, which you can control to target a desired outcome.

The Critical Role of Temperature

Temperature is the most significant control lever in pyrolysis. Different temperature ranges favor the formation of different products.

Lower temperatures, typically around 400–500 °C, maximize the yield of the solid product, biochar.

Higher temperatures, often above 700 °C, favor the production of liquid bio-oil and syngas by further breaking down the organic matter.

The Impact of Feedstock Moisture

The moisture content of the biomass feedstock is critical for process efficiency. An ideal moisture level is around 10%.

If the moisture is too high, the process wastes significant energy boiling off excess water. If it is too low, the feedstock can become dusty and difficult to process effectively.

Why Particle Size Matters

Most pyrolysis technologies require a small and consistent feedstock particle size, often less than 2 mm.

This ensures rapid and even heat transfer throughout each particle, leading to a more complete and efficient reaction. Larger particles heat unevenly, resulting in an inconsistent product mix.

Understanding the Products and Their Applications

Each output from the pyrolysis reaction has distinct properties and potential uses, turning what was once waste into a valuable resource.

The Solid Product: Biochar

Biochar is a stable, charcoal-like substance. Its primary applications are as a soil conditioner to improve soil health and water retention or as a specialized carbon material and catalyst carrier.

The Liquid Product: Bio-oil

Bio-oil is an energy-dense liquid that can be used directly for combustion in heating and electricity generation. It can also be refined into advanced transportation fuels or used as a source for specialty chemicals.

The Gaseous Product: Syngas

The non-condensable syngas produced during pyrolysis is a fuel. It is often captured and used to provide heat for the pyrolysis reactor itself, making the process more energy-efficient and self-sustaining.

Key Considerations and Trade-offs

While powerful, pyrolysis is a technical process with practical constraints that must be managed for a successful operation.

Feedstock Preparation is Non-Negotiable

The strict requirements for moisture content and particle size mean that biomass almost always requires pre-processing. The energy and cost associated with drying and grinding the feedstock must be factored into the overall efficiency and economics of the system.

Product Yield is a Balancing Act

You cannot simultaneously maximize the yield of all three products. A decision to optimize for biochar by using lower temperatures will inherently reduce the yield of bio-oil and syngas, and vice-versa. The process must be tuned to your primary goal.

Handling Complex Outputs

The output is not perfectly clean. The liquid stream often contains a mix of bio-oil, tar, and wood vinegar, which must be properly collected, separated, and managed. This adds a layer of complexity to the system design.

Applying This to Your Goal

Your strategy for implementing pyrolysis should be dictated by your end goal.

- If your primary focus is soil amendment or carbon sequestration: Run the process at lower temperatures (400-500°C) to maximize your yield of stable biochar.

- If your primary focus is creating liquid fuels or chemical feedstocks: Operate at higher temperatures (>700°C) to favor the thermal cracking that produces more bio-oil.

- If your primary focus is maximum energy efficiency or on-site power: Design the system to capture and combust the syngas to provide process heat, reducing external energy inputs.

Ultimately, biomass pyrolysis is a versatile conversion technology that allows you to transform organic liabilities into specified, high-value assets.

Summary Table:

| Key Factor | Impact on Pyrolysis Output |

|---|---|

| Temperature | Low (400-500°C) maximizes biochar; High (>700°C) favors bio-oil/syngas. |

| Moisture Content | Ideal ~10%; too high wastes energy, too low causes dust. |

| Particle Size | <2mm ensures even heating and consistent product yields. |

| Primary Goal | Dictates temperature setting: biochar (soil), bio-oil (fuel), or syngas (energy). |

Ready to harness the power of biomass pyrolysis in your lab? KINTEK specializes in high-quality lab equipment and consumables for precise thermal processing. Whether you're researching biochar for soil enhancement, bio-oil for renewable fuels, or syngas for energy recovery, our reliable pyrolysis systems help you achieve consistent, controlled results. Contact our experts today to discuss your laboratory needs and discover how KINTEK can support your innovation in sustainable biomass conversion.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Calciner Small Rotary Kiln Rotating Furnace

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What are the advantages of pyrolysis technology? Turn Waste into Profit and Reduce Emissions

- What are the reactions involved in pyrolysis of biomass? Unlock the Chemistry for Tailored Bio-Products

- What is the process of biomass fast pyrolysis? Turn Biomass into Bio-Oil in Seconds

- What are the conditions for biomass pyrolysis? Optimize Temperature, Heating Rate & Time

- What are the components of biomass pyrolysis? A Complete Guide to the System, Products, and Process