Ultimately, there is no single rate of deposition for Physical Vapor Deposition (PVD). The speed of the coating process is not a fixed value but a highly variable parameter that depends entirely on the specific PVD method being used, the material being deposited, and the desired quality of the final film. Typical commercial coating thicknesses range from 1 to 5 microns (.00004 to .0002 inches), but the time to achieve this can range from minutes to hours.

The core takeaway is that deposition rate in PVD is a fundamental trade-off. Faster methods like evaporation are excellent for high throughput, while slower methods like sputtering provide superior film quality, density, and control.

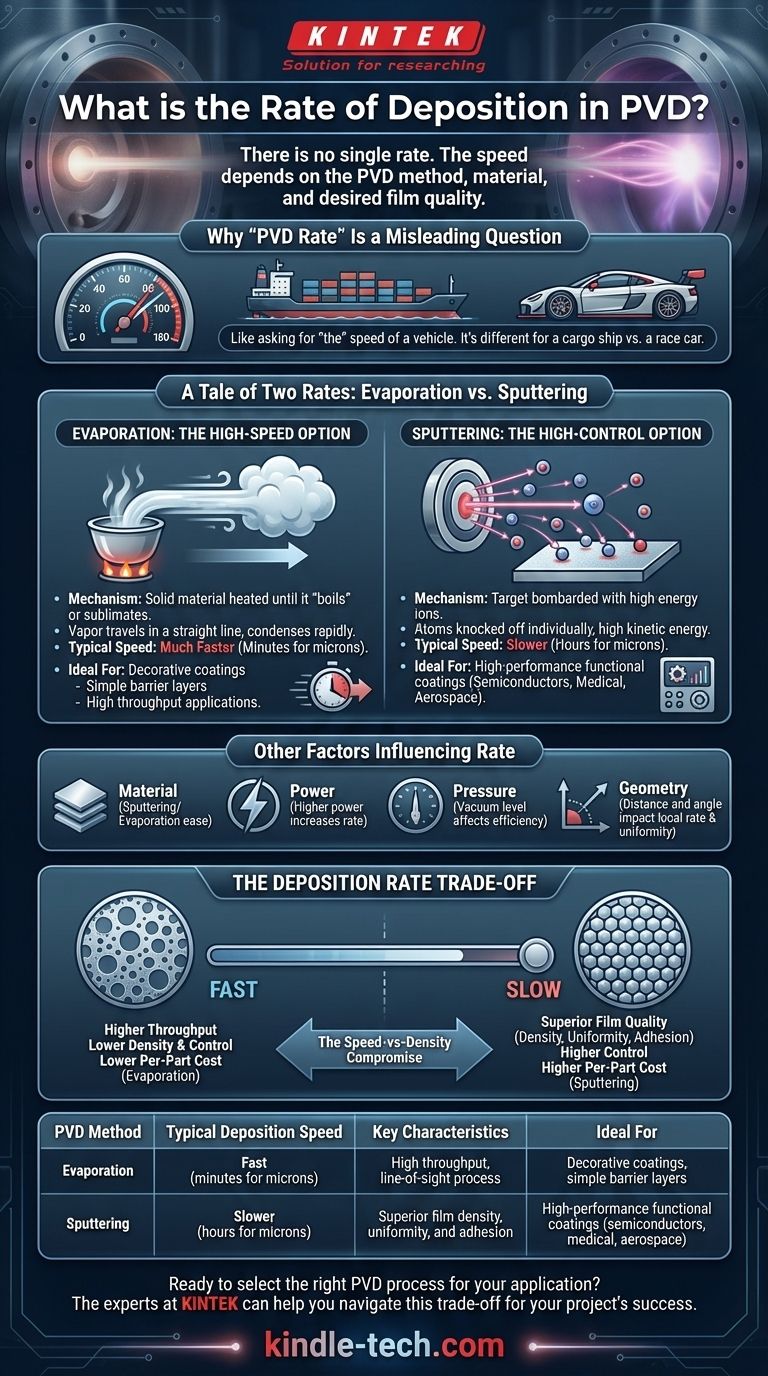

Why "PVD Rate" Is a Misleading Question

The term "PVD" is not a single process but a category of vacuum deposition techniques. Asking for "the" rate of PVD is like asking for "the" speed of a vehicle; the answer is entirely different for a cargo ship versus a race car.

The PVD Family of Processes

PVD encompasses several distinct methods, each with its own mechanism for turning a solid source material into a vapor that coats a substrate. The two most dominant industrial methods are evaporation and sputtering.

Mechanism Dictates Speed

The physical mechanism used to generate the vapor is the primary factor determining the deposition rate. Methods that generate vapor more aggressively are faster, while those that rely on a more controlled, atom-by-atom removal are inherently slower.

A Tale of Two Rates: Evaporation vs. Sputtering

Understanding the difference between evaporation and sputtering is key to understanding deposition rates and making the right process choice for your application.

Evaporation: The High-Speed Option

In evaporation (including thermal and e-beam methods), a source material is heated in a vacuum until it "boils" or sublimates, releasing a large volume of vapor. This vapor travels in a straight line and condenses on the cooler substrate.

This method is generally much faster than sputtering. It's often chosen for decorative coatings or applications where rapid throughput is a primary economic driver.

Sputtering: The High-Control Option

In sputtering, a target of the source material is bombarded with high-energy ions (a plasma) in a vacuum. This bombardment acts like a microscopic sandblaster, knocking individual atoms or molecules off the target, which then deposit onto the substrate.

This process is inherently slower but offers exceptional control. Because the sputtered atoms have higher kinetic energy, they form denser, more uniform, and more adherent films. This makes sputtering the standard for high-performance functional coatings in industries like semiconductors, aerospace, and medical devices.

Other Factors Influencing Rate

Beyond the core method, several other parameters affect the final deposition rate:

- Material: Some materials sputter or evaporate more readily than others.

- Power: Higher power applied to the source (e.g., to the sputtering target or e-beam) generally increases the rate.

- Pressure: The level of vacuum in the chamber affects the mean free path of atoms, influencing how efficiently they travel to the substrate.

- Geometry: PVD is a 'line-of-sight' process. The distance and angle between the source and the substrate directly impact the local deposition rate and film uniformity.

Understanding the Trade-offs: Rate vs. Film Quality

Choosing a PVD process is never just about speed. It is a calculated decision based on the trade-offs between manufacturing throughput and the functional requirements of the coating.

The Speed-vs-Density Compromise

A key trade-off is deposition rate versus film density. Faster evaporation processes often result in films that are less dense and more porous compared to the slow, atom-by-atom build-up from sputtering. For a simple decorative finish, this may not matter. For a hard, wear-resistant tool coating, it is a critical failure point.

The Cost of Control

The precise control over film properties like stoichiometry (for compounds), stress, and density offered by sputtering comes at the cost of time. Slower cycles mean lower throughput, which can translate to higher per-part costs. The equipment for sputtering is also often more complex and expensive.

The "Line of Sight" Limitation

All common PVD processes are 'line of sight,' meaning the coating material travels in a straight line from the source to the substrate. Complex parts may need to be rotated on sophisticated fixtures to achieve a uniform coating, which can add time and complexity to the process, effectively reducing the overall rate.

Making the Right Choice for Your Goal

The best PVD method is the one that meets your specific performance and economic goals. Your decision should be guided by the primary requirement of your application.

- If your primary focus is high throughput for decorative or simple barrier coatings: Evaporation is often the most cost-effective and fastest choice.

- If your primary focus is a high-performance functional coating (e.g., wear resistance, electrical properties, or corrosion resistance): Sputtering is almost always the superior technical choice, despite its slower rate.

- If your primary focus is extreme precision for research or advanced semiconductors: Highly specialized, and even slower, methods like Molecular Beam Epitaxy (MBE) are used where rate is a distant secondary concern to atomic-level control.

Ultimately, you must align the deposition process with the required outcome, balancing manufacturing speed against the necessary film quality.

Summary Table:

| PVD Method | Typical Deposition Speed | Key Characteristics | Ideal For |

|---|---|---|---|

| Evaporation | Fast (minutes for microns) | High throughput, line-of-sight process | Decorative coatings, simple barrier layers |

| Sputtering | Slower (hours for microns) | Superior film density, uniformity, and adhesion | High-performance functional coatings (semiconductors, medical, aerospace) |

Ready to select the right PVD process for your application?

Choosing between high-speed evaporation and high-quality sputtering is critical for your project's success. The experts at KINTEK can help you navigate this trade-off. We specialize in providing the right lab equipment and consumables to meet your specific coating needs, whether you prioritize throughput or ultimate film performance.

Contact KINTEK today to discuss your requirements and ensure your PVD process delivers the results you need.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- Electric Heated Hydraulic Vacuum Heat Press for Lab

People Also Ask

- What are the advantages of PECVD? Enable Low-Temperature, High-Quality Thin-Film Deposition

- Why is PECVD environment friendly? Understanding the Eco-Friendly Benefits of Plasma-Enhanced Coating

- What is the principle of plasma enhanced chemical vapor deposition? Achieve Low-Temperature Thin Film Deposition

- What are the benefits of PECVD? Achieve Superior Low-Temperature Thin Film Deposition

- What is plasma activated chemical vapour deposition method? A Low-Temperature Solution for Advanced Coatings