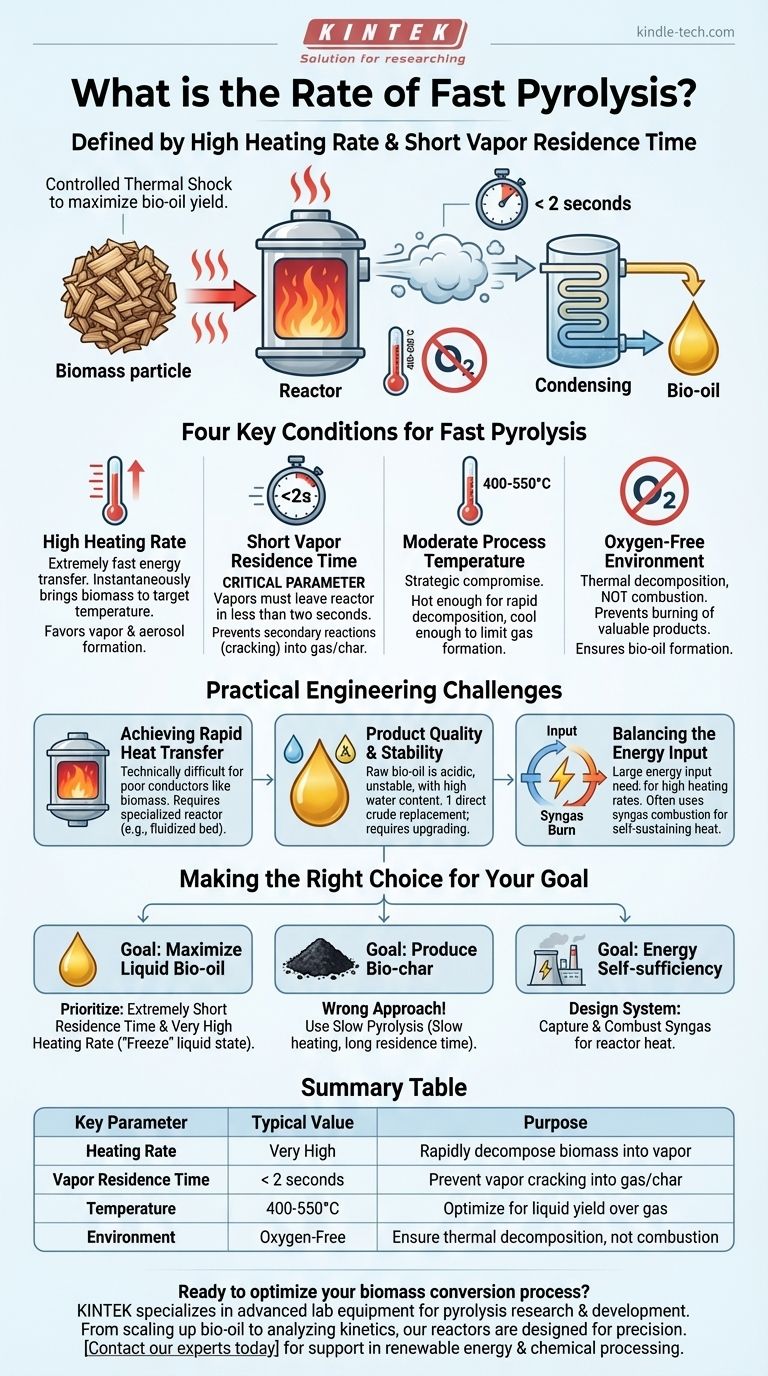

The rate of fast pyrolysis is defined by two key parameters: a very high heating rate and a very short vapor residence time, typically less than two seconds. This process occurs at moderate temperatures of 400-600°C in an environment without oxygen to thermally decompose biomass into a liquid bio-oil.

The term "rate" in fast pyrolysis refers not to a single speed but to a carefully controlled set of conditions. Success hinges on heating the biomass extremely quickly and then removing and cooling the resulting vapors almost instantly to maximize the liquid bio-oil yield.

What Defines the Speed of Fast Pyrolysis?

Fast pyrolysis is fundamentally an exercise in controlled thermal shock. The goal is to rapidly break down complex biomass structures (like cellulose and lignin) and immediately capture the valuable vapor intermediates before they can further react and degrade into less desirable products like char and gas.

High Heating Rate

The process requires an extremely high heating rate to bring the biomass particles to the target temperature almost instantaneously.

This rapid energy transfer ensures that the biomass decomposes quickly, favoring the formation of vapors and aerosols that can be condensed into bio-oil.

Short Vapor Residence Time

This is the most critical rate-defining parameter. The vapors produced during pyrolysis must be removed from the hot reactor zone in less than two seconds.

If vapors linger in the high-temperature environment, secondary reactions occur. These reactions crack the larger, valuable molecules into permanent, non-condensable gases (like methane and carbon monoxide) and solid char, drastically reducing the liquid bio-oil yield.

Moderate Process Temperature

The process is conducted at a carefully selected temperature, typically between 400°C and 550°C.

This temperature range is a strategic compromise. It is hot enough to achieve rapid decomposition but cool enough to limit the formation of gas, which becomes more favorable at higher temperatures.

Oxygen-Free Environment

The entire process must occur in the absence of oxygen.

This is the defining characteristic of pyrolysis versus combustion or gasification. The goal is thermal decomposition, not burning. Any oxygen present would cause the biomass and valuable products to burn, releasing energy as heat instead of forming liquid fuel.

Understanding the Practical Challenges

While the principles are straightforward, achieving these precise conditions at an industrial scale presents significant engineering challenges. The effectiveness of the process is directly tied to overcoming these hurdles.

Achieving Rapid Heat Transfer

Heating solid biomass particles, which are poor thermal conductors, at the required rates is technically difficult. Reactor designs, like ablative or fluidized bed reactors, are specifically engineered to maximize heat transfer to the particle surface.

Product Quality and Stability

The resulting raw bio-oil, also known as flash pyrolysis oil, is not a direct replacement for crude oil.

It has a high water content (often over 15%), is acidic, and can be chemically unstable. It requires significant upgrading to be used as a conventional transportation fuel.

Balancing the Energy Input

The process demands a large energy input to achieve high heating rates.

To improve efficiency, the non-condensable syngas produced alongside the bio-oil is often captured and burned. This provides the necessary heat to make the overall process more energy-efficient and self-sustaining.

Making the Right Choice for Your Goal

Controlling the rates and conditions of pyrolysis directly determines your final product distribution. Understanding your primary objective is key to optimizing the process.

- If your primary focus is maximizing liquid bio-oil: Prioritize an extremely short vapor residence time and a very high heating rate to "freeze" the reaction products in their liquid state.

- If your primary focus is producing bio-char: Fast pyrolysis is the wrong approach; you should use slow pyrolysis, which involves slow heating and very long residence times.

- If your primary focus is energy self-sufficiency: Design a system that effectively captures and combusts the produced syngas to provide the heat required for the reactor.

Mastering the interplay between heating rate and residence time is the key to successfully converting raw biomass into valuable liquid fuels and chemicals.

Summary Table:

| Key Parameter | Typical Value | Purpose |

|---|---|---|

| Heating Rate | Very High | Rapidly decompose biomass into vapor |

| Vapor Residence Time | < 2 seconds | Prevent vapor cracking into gas/char |

| Temperature | 400-550°C | Optimize for liquid yield over gas |

| Environment | Oxygen-Free | Ensure thermal decomposition, not combustion |

Ready to optimize your biomass conversion process? KINTEK specializes in advanced lab equipment for pyrolysis research and development. Whether you're scaling up bio-oil production or analyzing reaction kinetics, our reactors and consumables are designed for precision and reliability. Contact our experts today to discuss how we can support your laboratory's specific needs in renewable energy and chemical processing.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- Mini SS High Pressure Autoclave Reactor for Laboratory Use

- High Pressure Laboratory Autoclave Reactor for Hydrothermal Synthesis

- Stainless High Pressure Autoclave Reactor Laboratory Pressure Reactor

People Also Ask

- What are the conditions for biomass pyrolysis? Optimize Temperature, Heating Rate & Time

- How is energy converted into biomass? Harnessing Nature's Solar Power for Renewable Energy

- What are the different types of pyrolysis machines? Choose the Right System for Your Output

- What are the components of biomass pyrolysis? A Complete Guide to the System, Products, and Process

- What is the process of biomass fast pyrolysis? Turn Biomass into Bio-Oil in Seconds