In essence, plastic pyrolysis is a form of advanced recycling that uses intense heat in an oxygen-free environment to break down plastic waste. Instead of burning, this process thermally decomposes long, complex plastic polymer chains into simpler, more valuable products: a synthetic crude oil, a combustible gas, and a solid carbon residue. It is a method of chemical recycling because it fundamentally alters the chemical structure of the material.

The core purpose of pyrolysis is to convert low-value, hard-to-recycle plastic waste into a usable liquid hydrocarbon. While it presents a compelling solution for plastics that traditional recycling cannot handle, its true value depends on whether the resulting oil is used to create new plastics or simply burned as a one-time fuel.

How Pyrolysis Breaks Down Plastic

Pyrolysis is often called "thermal cracking" for a reason. It uses heat to crack the massive, long-chain molecules found in plastics into smaller, lighter, and more useful molecules.

The Core Principle: Heating Without Burning

The key to pyrolysis is the absence of oxygen. When you heat plastic with oxygen present, it combusts (burns), releasing energy, carbon dioxide, and harmful pollutants.

By removing oxygen, the plastic cannot burn. Instead, the intense heat (typically between 300°C and 900°C) breaks the chemical bonds holding the long polymer chains together, creating a mix of smaller hydrocarbon molecules.

The Inputs: What Goes In

The primary input is plastic waste. Pyrolysis is particularly valuable for handling mixed plastic streams or types that are difficult to recycle mechanically, such as:

- Low-density polyethylene (LDPE) films

- Polypropylene (PP) containers

- Polystyrene (PS)

However, the process is sensitive to certain contaminants. Plastics like PVC are highly problematic as they release corrosive chlorine gas, which can damage equipment and create toxic byproducts.

The Outputs: What Comes Out

The process typically yields three main products, with the proportions varying based on the type of plastic and the operating conditions.

- Pyrolysis Oil (Liquid): This is the main desired output, often representing 40-75% of the product by weight. It is a complex mixture of hydrocarbons similar to conventional crude oil and can be refined into diesel, gasoline, or other chemical feedstocks.

- Syngas (Gas): This non-condensable gas mixture includes hydrogen, methane, and carbon monoxide. It is highly combustible and is almost always used to power the pyrolysis reactor itself, reducing the process's reliance on external energy.

- Char (Solid): This solid, carbon-rich residue is similar to charcoal. Its quality can vary, but potential uses include as a solid fuel, an additive in asphalt, or as a soil amendment.

Why Consider Pyrolysis Over Traditional Recycling?

Pyrolysis is not meant to replace traditional mechanical recycling (melting and remolding) but to complement it by targeting waste streams that would otherwise end up in a landfill.

Tackling "Unrecyclable" Plastics

Mechanical recycling requires clean, sorted streams of specific plastic types. It struggles with contaminated materials (e.g., food residue), multi-layer packaging, and mixed plastic bales. Pyrolysis is far more tolerant of this type of low-grade feedstock.

Potential for a True Circular Economy

Mechanical recycling often results in downcycling—turning a high-quality food-grade bottle into a lower-quality fiber for a carpet or park bench. The material quality degrades with each cycle.

In theory, pyrolysis oil can be purified and used as a feedstock to create new, virgin-quality plastics. This "plastic-to-plastic" pathway offers a route to a truly circular economy where plastic can be regenerated indefinitely.

Reducing Landfill and Incineration

By providing a value-added pathway for non-recyclable plastic, pyrolysis directly diverts waste from landfills, where it can persist for hundreds of years. It is also seen as a more controlled alternative to mass-burn incineration.

Understanding the Trade-offs and Challenges

Despite its promise, pyrolysis is a complex industrial process with significant hurdles to overcome before it can be deployed at a massive scale.

High Energy Consumption

Bringing a reactor to the required high temperatures is energy-intensive. While the process can be partially self-sustaining by burning its own syngas, the overall net energy balance—the energy produced minus the energy consumed—is a critical point of analysis and debate.

Contaminant Management

The quality of the final pyrolysis oil is directly tied to the quality of the incoming plastic waste. Contaminants like flame retardants, pigments, and heavy metals present in the original plastic can be carried over into the oil and char, requiring costly, energy-intensive purification steps before they can be used.

Economic Viability

Pyrolysis facilities have high capital and operational costs. Their profitability is often tied to the fluctuating market price of crude oil. If crude oil is cheap, producing synthetic oil from plastic waste may not be economically competitive.

The "Plastic-to-Fuel" Criticism

A major point of contention is how the final oil is used. If it is simply burned as fuel ("plastic-to-fuel"), critics argue pyrolysis is just a complex, two-step form of incineration. To achieve true circularity and maximum environmental benefit, the process must be part of a "plastic-to-plastic" supply chain, which is currently the more difficult and expensive path.

Making the Right Choice for Your Goal

Deciding whether pyrolysis is a viable solution depends entirely on the specific objective for managing a given stream of plastic waste.

- If your primary focus is diverting mixed, low-quality plastic from landfills: Pyrolysis offers a powerful chemical conversion alternative to burying or burning waste that traditional recycling cannot process.

- If your primary focus is creating a true circular economy: The goal must be a "plastic-to-plastic" pathway, requiring significant investment in refining the pyrolysis oil into a feedstock for new polymers.

- If your primary focus is localized energy production: Pyrolysis can convert plastic waste into a liquid fuel, but you must carefully evaluate the net energy balance and environmental emissions compared to other energy sources.

Ultimately, pyrolysis transforms plastic from a physical material to be managed into a chemical feedstock to be utilized.

Summary Table:

| Aspect | Key Takeaway |

|---|---|

| Process | Thermal decomposition of plastic in an oxygen-free environment. |

| Main Input | Mixed or hard-to-recycle plastic waste (e.g., LDPE, PP, PS). |

| Primary Output | Pyrolysis oil (a synthetic crude), syngas, and solid char. |

| Key Advantage | Diverts non-recyclable plastic from landfills and enables circularity. |

| Main Challenge | High energy consumption and economic viability tied to oil prices. |

Ready to explore advanced solutions for your laboratory's material challenges? The principles of chemical transformation, like pyrolysis, are at the heart of modern R&D. KINTEK specializes in providing the high-quality lab equipment and consumables you need to innovate. Whether you're researching recycling technologies or developing new materials, our products support precision and reliability. Let's discuss your project needs—contact our experts today to find the right tools for your success.

Related Products

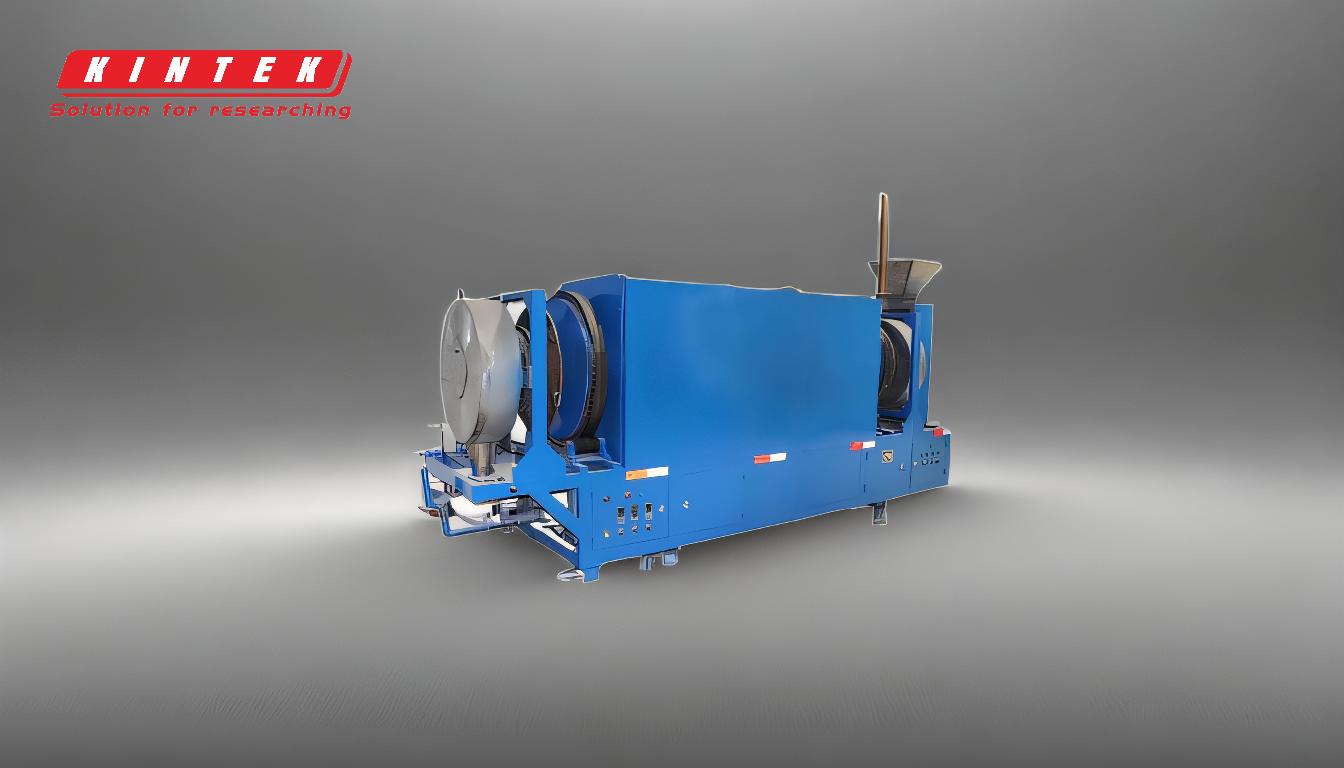

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- Mini SS High Pressure Autoclave Reactor for Laboratory Use

- Stainless High Pressure Autoclave Reactor Laboratory Pressure Reactor

- High Pressure Laboratory Autoclave Reactor for Hydrothermal Synthesis

People Also Ask

- What is pyrolysis technology for biomass energy? Unlock Bio-Oil, Biochar, and Syngas from Waste

- What biomass is used in pyrolysis? Selecting the Optimal Feedstock for Your Goals

- What are the steps of biomass pyrolysis? Turn Waste into Biochar, Bio-Oil & Biogas

- How is energy converted into biomass? Harnessing Nature's Solar Power for Renewable Energy

- What is a disadvantage of biomass energy? The Hidden Environmental and Economic Costs