In slow pyrolysis, the residence time is a deliberately long duration measured in hours, not minutes or seconds. While there is no single universal value, the process involves heating biomass gradually in an oxygen-free environment for several hours, and sometimes even days in traditional kiln methods. This extended time is the defining characteristic that ensures the primary output is a stable, high-carbon solid known as biochar.

The core principle of slow pyrolysis is to sacrifice speed for product quality. The extended residence time—ranging from 1 to over 12 hours—is not a byproduct but a deliberate process parameter designed to maximize the conversion of biomass into solid biochar, rather than the liquids and gases favored by faster methods.

What Defines "Slow" Pyrolysis?

Slow pyrolysis is defined by a combination of a low heating rate and a long residence time. These two parameters are intrinsically linked and work together to control the final product distribution.

The Critical Role of Heating Rate

The process begins with a very low heating rate, typically between 1°C and 30°C per minute. This gradual increase in temperature prevents the violent breakdown of biomass that occurs in fast pyrolysis.

This slow heating allows thermal energy to fully penetrate the feedstock, initiating a controlled, sequential breakdown of organic compounds like cellulose, hemicellulose, and lignin.

The Goal: Maximizing Biochar Yield

The primary objective of slow pyrolysis is to produce the maximum possible yield of biochar. The long residence time is essential for achieving this.

During this extended period, volatile compounds that are initially released have more time to interact with the hot solid surfaces. This can lead to secondary charring reactions, where some vapors crack and deposit additional carbon onto the biochar, increasing the overall solid yield.

Residence Time: Hours, Not Seconds

The "residence time" refers to the total time the biomass spends in the heated reactor. For slow pyrolysis, this typically ranges from one to several hours at the target temperature (e.g., 400-600°C).

This stands in stark contrast to fast pyrolysis, where residence times are just a few seconds, designed to rapidly vaporize the biomass and capture the resulting liquids (bio-oil).

Understanding the Trade-offs: Slow vs. Fast Pyrolysis

Choosing a pyrolysis method involves a fundamental trade-off between the desired product, processing speed, and system complexity. The residence time is at the heart of this decision.

The Primary Product Trade-off

Slow pyrolysis, with its long residence time, is optimized for producing solid biochar. Yields can exceed 35% by weight.

Fast pyrolysis, with its residence time of seconds, is optimized for producing liquid bio-oil. Liquid yields can be over 60%, while biochar is often a lower-value co-product.

Throughput and Scale

Slow pyrolysis is inherently a low-throughput process. A batch that takes several hours to complete can only process a limited amount of feedstock per day. This makes it well-suited for decentralized or smaller-scale operations.

Fast pyrolysis systems are engineered for high throughput, capable of processing large volumes of biomass continuously, which is necessary for industrial-scale biofuel production.

System Simplicity vs. Complexity

Slow pyrolysis reactors can be relatively simple in design, such as traditional kilns or basic screw reactors. The long residence time makes precise control less critical than in fast systems.

Fast pyrolysis requires more complex engineering, like fluidized bed or ablative reactors, to achieve rapid heat transfer and short vapor residence times.

Making the Right Choice for Your Goal

Understanding the role of residence time is crucial for aligning the pyrolysis process with your specific objective.

- If your primary focus is high-quality biochar for soil amendment or carbon sequestration: Slow pyrolysis with a residence time of several hours is the correct method to maximize char yield and stability.

- If your primary focus is producing liquid biofuels (bio-oil): Fast pyrolysis, with a residence time of only a few seconds, is the required approach and slow pyrolysis is unsuitable.

- If your primary focus is a balanced mix of char, oil, and gas (syngas): Intermediate pyrolysis, with a residence time of several minutes, may be the most appropriate choice.

Ultimately, residence time is the key lever an operator uses to determine whether the final product will be a solid, a liquid, or a gas.

Summary Table:

| Process Parameter | Slow Pyrolysis | Fast Pyrolysis |

|---|---|---|

| Primary Goal | Maximize Biochar Yield | Maximize Bio-Oil Yield |

| Typical Residence Time | 1 to 12+ hours | A few seconds |

| Typical Heating Rate | 1°C to 30°C per minute | Very high (>100°C/sec) |

| Primary Product Yield | Biochar (>35%) | Bio-Oil (>60%) |

Ready to optimize your biomass conversion process?

Whether your goal is high-yield biochar production for carbon sequestration or a different pyrolysis outcome, KINTEK has the expertise and equipment to help. We specialize in providing robust lab equipment and consumables tailored to your research and development needs.

Contact our experts today to discuss how our solutions can enhance your laboratory's efficiency and results.

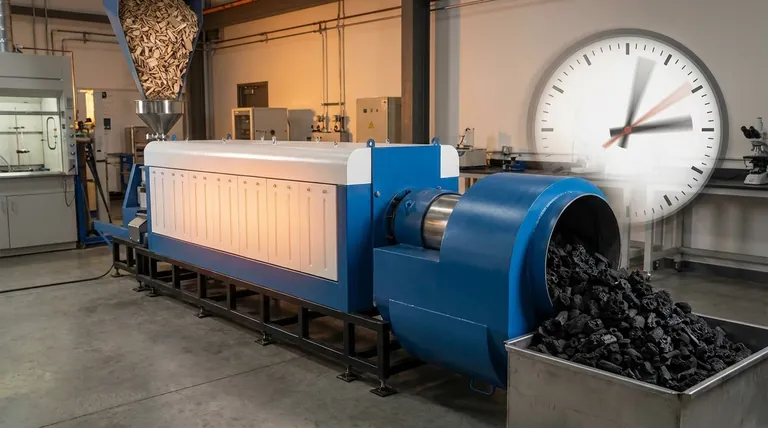

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Calciner Small Rotary Kiln Rotating Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- High Pressure Laboratory Autoclave Reactor for Hydrothermal Synthesis

People Also Ask

- What is a disadvantage of biomass energy? The Hidden Environmental and Economic Costs

- What are the different types of pyrolysis machines? Choose the Right System for Your Output

- What are the reactions involved in pyrolysis of biomass? Unlock the Chemistry for Tailored Bio-Products

- How is energy converted into biomass? Harnessing Nature's Solar Power for Renewable Energy

- What are the conditions for biomass pyrolysis? Optimize Temperature, Heating Rate & Time