At its core, the sputtering cathode method is a physical vapor deposition (PVD) technique used to create ultra-thin films. The process involves placing a solid material, known as the target, into a vacuum chamber and bombarding it with high-energy ions from a plasma. These ion collisions are energetic enough to physically knock atoms off the target's surface, which then travel and condense onto a substrate, forming the desired thin film.

Sputtering is best understood not as a chemical reaction or a melting process, but as a physical momentum transfer. Think of it as a subatomic sandblasting, where individual atoms of a source material are dislodged by ion impacts and then re-deposited with high precision onto another surface.

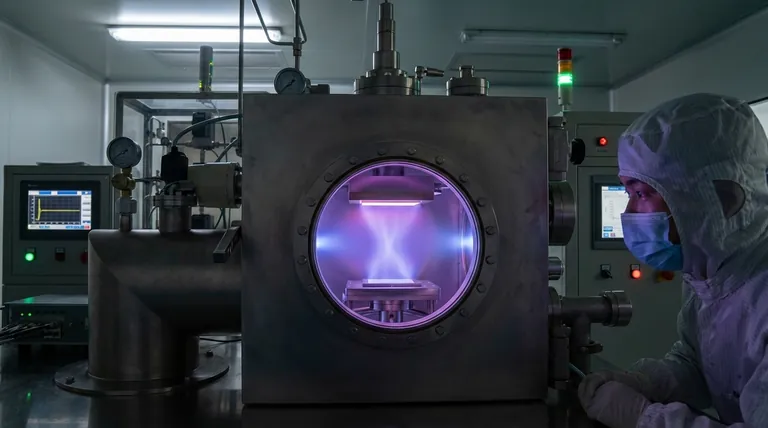

How Sputtering Works: A Step-by-Step Breakdown

To truly grasp the sputtering method, it's essential to understand the controlled sequence of events that takes place inside the vacuum chamber.

The Vacuum Environment

First, a substrate (the object to be coated) and a target (the coating material) are placed in a high-vacuum chamber. This vacuum is critical for removing contaminants and ensuring the sputtered atoms can travel freely from the target to the substrate without unwanted collisions.

Introducing the Gas and Creating Plasma

A small, controlled amount of an inert gas, almost always Argon (Ar), is introduced into the chamber. A strong DC electric field is then applied, designating the target as the negative electrode (cathode) and the substrate as the positive electrode (anode). This field energizes the gas, stripping electrons from the argon atoms and creating a glowing, ionized gas known as a plasma.

The Role of the Cathode (The Target)

The plasma is now a high-energy soup of positive argon ions (Ar+) and free electrons. Because opposite charges attract, the positively charged Ar+ ions are forcefully accelerated towards the negatively charged target (cathode).

Ion Bombardment: The "Sputter" Event

These high-energy Ar+ ions collide with the surface of the target. The impact transfers kinetic energy from the ion to the target material, much like a cue ball striking a rack of billiard balls. This energy transfer is sufficient to eject, or "sputter," individual atoms from the target's surface.

Deposition: Building the Thin Film

The newly freed atoms from the target material travel through the vacuum chamber and land on the surface of the substrate. As more and more atoms arrive, they condense and build upon one another, forming a dense, uniform, and extremely thin film.

Understanding the Trade-offs

Sputtering is a powerful and versatile technique, but it's not universally applicable. Understanding its strengths and weaknesses is key to using it effectively.

Strength: High-Melting-Point Materials and Alloys

Sputtering excels where other methods, like thermal evaporation, fail. Because it is a physical and not a thermal process, it can easily deposit materials with extremely high melting points (e.g., tungsten, tantalum) and complex alloys without altering their composition.

Strength: Excellent Film Adhesion

The sputtered atoms arrive at the substrate with considerable kinetic energy, which helps them form a very dense and strongly bonded film. The process can also include a "cathodic cleaning" step, where the polarity is temporarily reversed to bombard the substrate with ions, cleaning its surface of contaminants and further improving film adhesion.

Limitation: Basic DC Sputtering and Insulators

The basic method described here, DC sputtering, works only for electrically conductive targets (metals). If the target is an insulator, the positive charge from the arriving Ar+ ions cannot dissipate. This charge buildup eventually repels further ions, stopping the sputtering process entirely. More advanced techniques, like RF sputtering, are required for insulating materials.

Variation: Reactive Sputtering

This limitation can be turned into an advantage. By introducing a reactive gas (like Nitrogen or Oxygen) along with the Argon, you can perform reactive sputtering. For example, by sputtering a titanium target in the presence of nitrogen gas, the sputtered titanium atoms react with the nitrogen to form a titanium nitride (TiN) film on the substrate—a hard, wear-resistant ceramic coating.

How to Apply This to Your Project

Choosing the right deposition method depends entirely on your material and your desired outcome.

- If your primary focus is depositing a pure metal or a metallic alloy: DC sputtering is an ideal, reliable, and highly controlled method, especially for materials that are difficult to melt.

- If your primary focus is creating a hard ceramic coating like a nitride or oxide: Reactive sputtering provides a precise way to form these compound films directly on your substrate.

- If your primary focus is coating a non-conductive material (like glass or a ceramic): Basic DC sputtering is not the right tool; you must investigate alternative techniques like RF (Radio Frequency) sputtering.

Ultimately, the sputtering cathode method provides an exceptional level of control for engineering surfaces at the atomic level.

Summary Table:

| Key Aspect | Description |

|---|---|

| Process Type | Physical Vapor Deposition (PVD) |

| Main Use | Creating ultra-thin films on substrates |

| Target Materials | Metals, alloys, high-melting-point materials |

| Best For | Conductive materials, alloy deposition, reactive coating |

| Limitation | Cannot directly sputter insulating materials with basic DC method |

Ready to enhance your thin film deposition capabilities? KINTEK specializes in laboratory sputtering equipment and consumables for research and industrial applications. Whether you're working with metals, alloys, or need reactive sputtering capabilities, our experts can help you select the right system for your specific needs. Contact us today to discuss how our sputtering solutions can advance your materials research and development projects!

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Electron Beam Evaporation Coating Oxygen-Free Copper Crucible and Evaporation Boat

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

People Also Ask

- What is the hot filament chemical vapor deposition method? A Guide to High-Quality Thin Film Deposition

- What temperature does deposition occur? Unlocking the Key Factors for Your Process

- What is the process of MOCVD in nanotechnology? Precision Growth of Thin Films for Semiconductors

- What is the mechanism of DC sputtering? A Step-by-Step Guide to Thin Film Deposition

- What industries utilize the vacuum deposition process? Unlocking Precision in Electronics, Energy, and Healthcare

- What are the steps of the chemical vapor deposition in order? A Guide to the CVD Process Flow

- What is the atmospheric pressure CVD process? A Guide to High-Purity Thin Film Deposition

- What is CVD in semiconductor? The Core Process for Building Modern Microchips