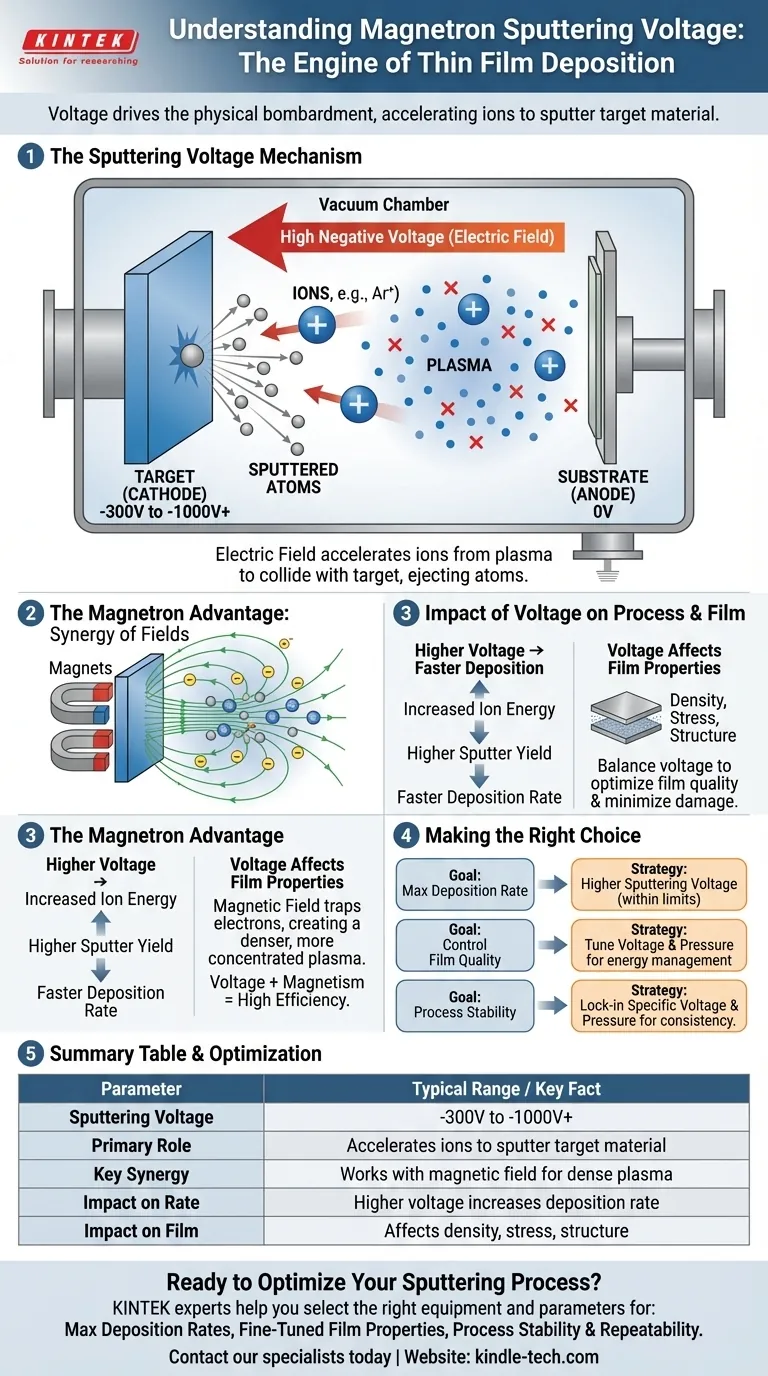

In magnetron sputtering, the process is driven by a high negative voltage applied to the target material, typically in the range of -300 volts to several kilovolts (-300V to -1000V+). This voltage creates a powerful electric field that attracts and accelerates positive ions from a generated plasma, causing them to collide with the target with enough force to eject, or "sputter," atoms from its surface.

The sputtering voltage is not just a static number; it is the primary accelerator in the deposition process. Its role is to give plasma ions the kinetic energy needed to physically dislodge material from a target, a process made vastly more efficient by a complementary magnetic field.

The Role of Voltage in Igniting the Sputtering Process

To understand magnetron sputtering, you must see the voltage as the engine that drives the physical bombardment at the heart of the process. Without it, there is no sputtering.

Establishing the Electric Field

The target material, from which the film will be made, functions as a cathode. When a high negative voltage is applied to this target within the vacuum chamber, it creates a strong electric field between the target and the chamber walls or substrate holder (which act as the anode).

Accelerating the Ions

This electric field is the crucial force-imparting element. Positively charged ions, typically from an inert gas like Argon that has been introduced into the chamber, are drawn irresistibly from the plasma and accelerated directly toward the negatively charged target surface.

The Collision and Sputtering Event

Upon impact, an ion transfers its kinetic energy to the atoms on the target's surface. If the energy transferred is greater than the surface binding energy of the target material, a target atom is physically ejected. This liberated atom then travels through the vacuum and deposits onto the substrate, building the thin film one atom at a time.

Why Voltage Isn't the Whole Story: The 'Magnetron' Advantage

While voltage provides the force for sputtering, the "magnetron" part of the name points to the innovation that makes the process so efficient: a magnetic field.

The Function of the Magnetic Field

Powerful magnets are placed behind the target. This magnetic field is designed to trap electrons near the face of the target, forcing them into long, spiral paths instead of allowing them to escape directly to the anode.

Creating a Dense Plasma

By trapping these electrons, the magnetic field dramatically increases the probability that they will collide with and ionize neutral gas atoms (e.g., Argon). This action creates a much denser, more concentrated plasma directly in front of the target where it is most needed.

The Synergy of Fields

The electric field (from the voltage) and the magnetic field work in perfect synergy.

- The magnetic field acts as a multiplier, efficiently creating a large supply of positive ions.

- The electric field acts as the accelerator, giving those ions the high velocity required for an effective sputtering collision.

Understanding the Key Variables

The sputtering voltage is a critical control parameter, but it does not exist in isolation. Adjusting it has direct consequences on the deposition process and the final product.

Impact of Voltage on Deposition Rate

As a general rule, a higher sputtering voltage results in ions striking the target with greater energy. This increases the "sputter yield"—the number of target atoms ejected per incident ion—which directly leads to a faster deposition rate.

Impact on Film Properties

However, simply maximizing voltage for speed is not always the goal. The energy of the sputtered atoms affects the properties of the resulting thin film, including its density, internal stress, and crystalline structure. Very high voltages can sometimes lead to film damage or undesirable stress levels.

The Pressure-Voltage Relationship

Magnetron sputtering operates in a low-pressure (vacuum) environment. The voltage and chamber pressure are codependent variables. A certain minimum voltage is required to ignite and sustain the plasma at a given pressure, a relationship described by Paschen's Law.

Making the Right Choice for Your Goal

Controlling the sputtering voltage is about balancing competing priorities. Your ideal voltage setting depends entirely on what you want to achieve with your thin film.

- If your primary focus is maximizing deposition rate: Employ a higher sputtering voltage within the limits of your material and power supply to increase sputter yield.

- If your primary focus is controlling film quality: Carefully tune the voltage, often starting lower, in conjunction with gas pressure to manage the energy of deposited atoms and minimize film stress.

- If your primary focus is process stability and repeatability: Lock in a specific voltage and pressure combination that provides a stable plasma and consistent film properties across multiple runs.

Ultimately, mastering sputtering voltage is about understanding its role as the accelerator in a system made efficient by magnetism.

Summary Table:

| Parameter | Typical Range / Key Fact |

|---|---|

| Sputtering Voltage | -300 V to -1000 V+ |

| Primary Role | Accelerates ions to sputter target material |

| Key Synergy | Works with a magnetic field to create dense plasma |

| Impact on Rate | Higher voltage generally increases deposition rate |

| Impact on Film | Affects film density, stress, and structure |

Ready to Optimize Your Sputtering Process?

Understanding the precise control of sputtering voltage is key to achieving high-quality, consistent thin films. The experts at KINTEK specialize in lab equipment and consumables for all your deposition needs.

We can help you select the right equipment and parameters to:

- Maximize deposition rates without compromising film integrity.

- Fine-tune film properties like density and stress for your specific application.

- Ensure process stability and repeatability for reliable results run after run.

Contact our specialists today to discuss how KINTEK's solutions can enhance your laboratory's capabilities and drive your research forward.

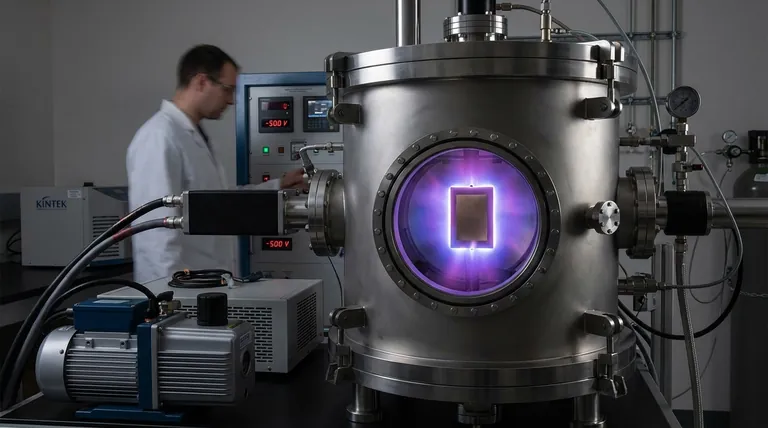

Visual Guide

Related Products

- Spark Plasma Sintering Furnace SPS Furnace

- Vacuum Induction Melting Spinning System Arc Melting Furnace

- Graphite Vacuum Furnace IGBT Experimental Graphitization Furnace

- Ultra-High Temperature Graphite Vacuum Graphitization Furnace

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

People Also Ask

- What is the importance of the sintering process in manufacturing? Unlocking Precision and Material Durability

- What is the role of an incubator shaker in preparing contaminated silicone? Standardize Your Sterilization Studies

- Does graphite shrink? The Critical Role of Temperature and Radiation in Dimensional Stability

- How hot can metal get? From Melting Points to Plasma Temperatures

- How plastic can be used as fuel? Turn Waste into Energy with Pyrolysis & Photo-Reforming

- What is the temperature of brazing alloys? Mastering the Critical Liquidus Point for Strong Joints

- What are the key considerations for stirring equipment for high-viscosity oils? Optimize Solvent-Free Catalytic Reduction

- Why KBr pellets are used to prepare solid samples in FTIR? Achieve Clear, Reliable Solid Analysis