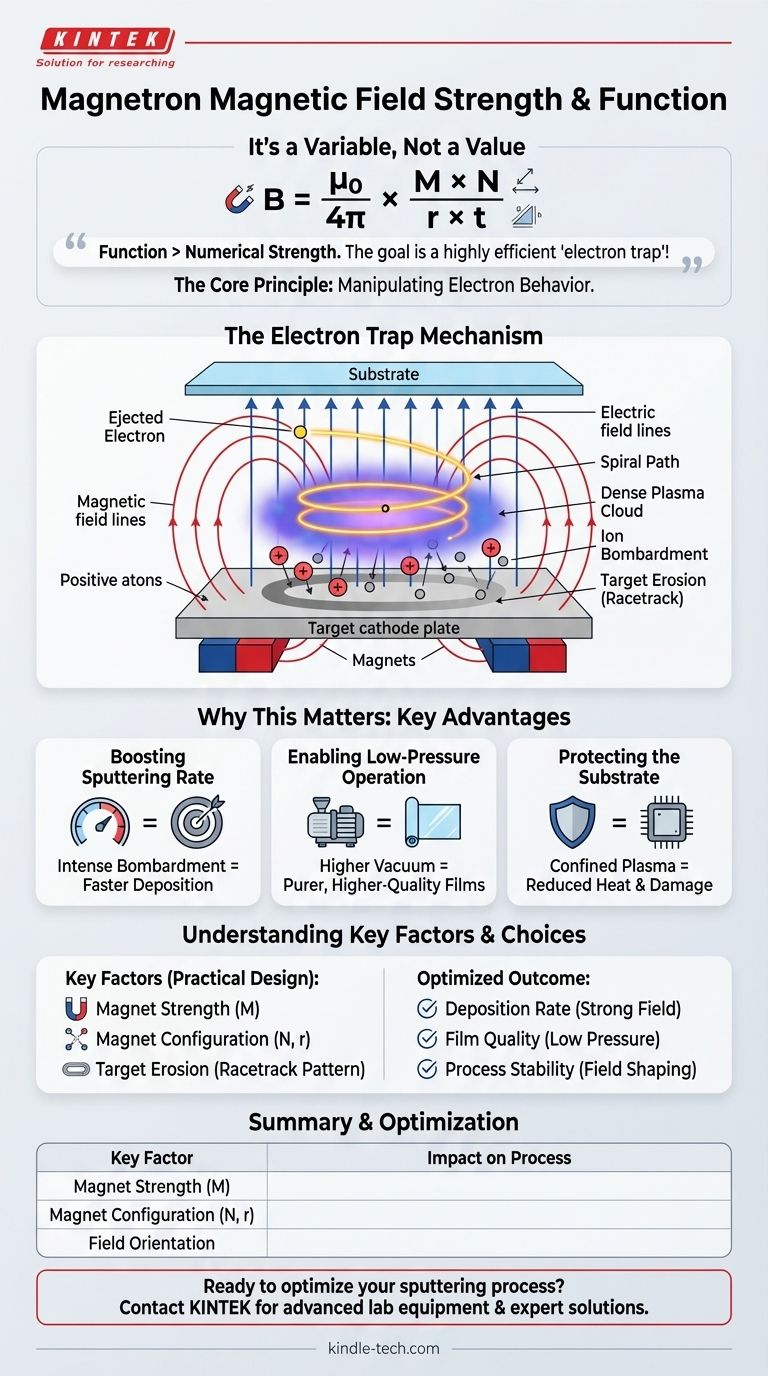

To be direct, the strength of a magnetron's magnetic field is not a single, universal value. It is a calculated variable dependent on the physical design of the sputtering system, specifically the material, size, number, and placement of the magnets used. The strength (B) can be estimated using the formula: B = (μ0/4π) x (M x N)/(r x t), where M is the magnet's magnetization, N is the number of magnets, and r and t relate to their geometry.

The specific numerical strength of the magnetic field is less important than its function. The true purpose of the field is to work in tandem with an electric field to create a highly efficient "electron trap" right above the target material, which is the core principle that makes magnetron sputtering effective.

The Role of the Magnetic Field in Sputtering

Understanding the magnetron requires shifting focus from the field's absolute strength to its strategic purpose: manipulating electron behavior to create a dense plasma.

It's Not About Brute Force

The key is the magnetic field's orientation, not just its power. In a magnetron, the magnetic field is designed to be parallel to the face of the cathode (the sputtering target).

This field is positioned to intersect with the electric field, which runs perpendicular to the target. This orthogonal arrangement is the critical design feature.

Trapping Electrons for Maximum Efficiency

When a voltage is applied, electrons are ejected from the target. Without a magnetic field, they would travel in a straight line, with few collisions.

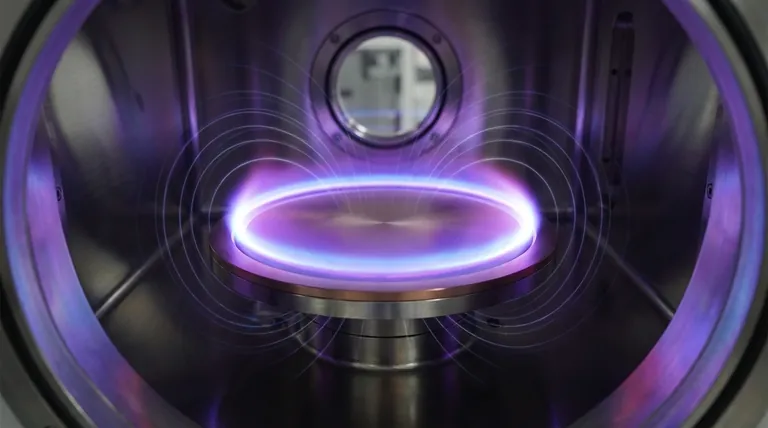

The magnetic field forces these electrons into a spiral, circular path, confining them to a region just above the target. This drastically increases their travel distance before they eventually reach the anode.

This confinement effectively creates an electron trap, ensuring each electron has the highest possible chance of colliding with a neutral gas atom (like argon).

Creating a Dense Plasma Cloud

These high-energy collisions knock electrons off the neutral gas atoms, turning them into positively charged ions.

Because the electrons are trapped near the target, this ionization happens in a concentrated, dense cloud right where it's needed most. This dense plasma is the engine of the sputtering process.

Why This Trapping Mechanism Matters

The efficiency gained by trapping electrons provides several profound advantages that define modern sputtering processes.

Boosting the Sputtering Rate

The dense cloud of positive ions is accelerated by the electric field and bombards the target material with immense force and frequency.

This intense bombardment ejects target atoms at a much higher rate than would be possible without the magnetic confinement, leading to faster deposition on the substrate.

Enabling Low-Pressure Operation

Without magnetic trapping, achieving a high ionization rate would require a much higher gas pressure to ensure enough collisions.

The magnetron's efficiency allows the entire process to run in a higher vacuum. This reduces the chance of gas atoms getting incorporated into the deposited film, resulting in a purer, higher-quality coating.

Protecting the Substrate

By confining the high-energy electrons and dense plasma near the cathode, the magnetron system prevents them from bombarding and potentially damaging the substrate being coated. This reduces heat load and defects.

Understanding the Key Factors

The variables in the magnetic field formula directly translate to practical design choices that control the process.

Magnet Material and Strength (M)

The magnetization (M) of the permanent magnets is a primary factor. Stronger magnets, like those made from neodymium, create a more effective electron trap, leading to a denser plasma.

Magnet Configuration (N, r)

The number (N) and distance (r) of the magnets define the shape of the magnetic field. This shape creates the distinct "racetrack" pattern of intense plasma on the target surface.

Target Erosion

A direct consequence of this "racetrack" is that the target material erodes unevenly. Understanding the magnetic field geometry is critical for predicting and managing this erosion to maximize target life and process stability.

Making the Right Choice for Your Goal

The configuration of the magnetic field is optimized based on the desired outcome of the sputtering process.

- If your primary focus is deposition rate: A stronger, well-configured magnetic field is critical for creating the dense plasma needed for high-speed sputtering.

- If your primary focus is film quality: The magnetic field's ability to enable low-pressure operation is key to reducing gas incorporation and improving film purity.

- If your primary focus is process stability: Understanding how the field shapes the plasma helps you manage the target's erosion racetrack and maintain consistent results over time.

Ultimately, the magnetic field is the crucial component that transforms basic sputtering into a highly efficient and controllable thin-film deposition technology.

Summary Table:

| Key Factor | Impact on Process |

|---|---|

| Magnet Strength (M) | Determines the effectiveness of the electron trap, influencing plasma density. |

| Magnet Configuration (N, r) | Defines the "racetrack" erosion pattern on the target, affecting process stability. |

| Field Orientation | Works with the electric field to confine electrons, enabling low-pressure operation for purer films. |

Ready to optimize your sputtering process? The precise design of the magnetron's magnetic field is critical for achieving high deposition rates, superior film quality, and process stability. At KINTEK, we specialize in advanced lab equipment and consumables for thin-film deposition. Our experts can help you select or configure the right sputtering system for your specific research or production goals.

Contact our team today to discuss how we can enhance your laboratory's capabilities.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Platinum Sheet Electrode for Laboratory and Industrial Applications

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

- Cylindrical Lab Electric Heating Press Mold for Laboratory Applications

- Graphite Vacuum Continuous Graphitization Furnace

People Also Ask

- How do nanotubes affect the environment? Balancing Low Carbon Footprint with Ecological Risks

- What is the effect of temperature on hydrogen embrittlement? The Critical Role of Temperature in Material Failure

- What are the 3 most important factors in material heat treatment? Control Temperature, Time, and Cooling Rate

- What is a filter press used for? Achieve Maximum Solid-Liquid Separation Efficiency

- What are the principles of physical vapour deposition? A Guide to Vacuum-Based Thin Film Coating

- Why is biomass a renewable resource? Key Principles for Sustainable Energy

- What is the debinding process? A Guide to Critical Binder Removal for MIM & 3D Printing

- Why are high-energy homogenizers required for high-performance microbial biopolymers? Achieving Superior Dispersion