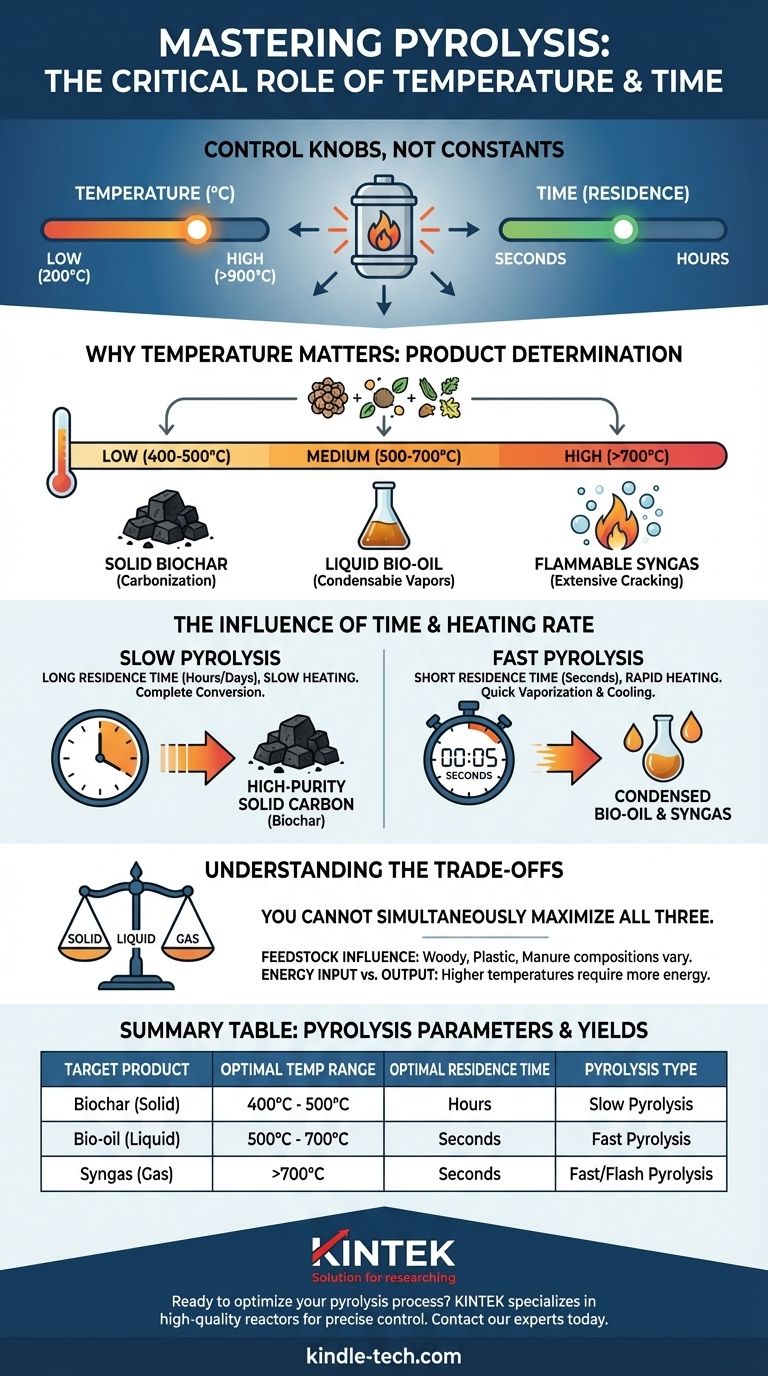

The temperature and time for pyrolysis are not fixed values. Instead, they are critical parameters that are deliberately manipulated to achieve a specific outcome. While the process can begin at temperatures as low as 200-300°C, typical operational ranges are between 400°C and 900°C, with the duration varying from a few seconds to several hours.

The core principle to understand is that temperature and time are not constants, but rather control knobs. Lower temperatures and longer times favor solid products like biochar, while higher temperatures and shorter times favor the production of liquid bio-oils and flammable gases.

Why Temperature is a Control, Not a Constant

To master pyrolysis, you must stop thinking of temperature as a simple setting and start seeing it as your primary tool for dictating the final product. The process is entirely about controlled thermal decomposition in the absence of oxygen.

The Fundamental Goal: Thermal Decomposition

Pyrolysis is the process of breaking down complex organic materials (like wood, plastic, or agricultural waste) into simpler, more valuable substances using heat.

The specific temperature you apply determines which chemical bonds break and what new substances are formed from the resulting fragments.

Linking Temperature to Products

The product distribution—solid, liquid, or gas—is a direct function of the process temperature.

- Low Temperatures (approx. 400-500°C) favor the production of solid biochar. At these temperatures, volatile compounds are driven off, but much of the fixed carbon structure remains intact.

- Medium Temperatures (approx. 500-700°C) are optimized to produce liquid bio-oil. This is often considered the "sweet spot" where large organic molecules break down into smaller, condensable vapors.

- High Temperatures (approx. >700°C) cause extensive cracking of all chemical bonds, maximizing the yield of non-condensable, flammable gases known as syngas (primarily hydrogen and carbon monoxide).

The Critical Role of Time and Heating Rate

The duration of the process, known as residence time, and the speed at which the material is heated are just as important as the final temperature.

Slow Pyrolysis (Carbonization)

This method uses slow heating rates over long residence times, often lasting several hours or even days.

The extended time at lower temperatures ensures a complete conversion of the feedstock into a high-purity solid carbon product. This is the traditional method for making charcoal.

Fast Pyrolysis

This process uses very rapid heating rates and extremely short residence times, typically just a few seconds.

The goal is to quickly vaporize the feedstock and immediately cool the vapors to condense them into liquid bio-oil before they can break down further into gas.

Understanding the Trade-offs

Choosing your pyrolysis parameters is always an exercise in balancing competing factors. There is no single "best" method, only the best method for a specific goal.

The Product Yield Trilemma: Solid, Liquid, or Gas?

You cannot simultaneously maximize the output of all three product types. The conditions that are ideal for producing high-quality biochar are fundamentally poor for producing syngas, and vice-versa.

Your process design must start with a clear decision on which product stream—solid, liquid, or gas—is your primary target.

The Influence of Feedstock

The type of material you are processing matters significantly. Woody biomass, plastics, and manure all have different chemical compositions.

Each feedstock has an optimal temperature and time profile to achieve a desired product, requiring careful tuning and experimentation.

Energy Input vs. Energy Output

Higher-temperature processes like gasification require a much greater energy input to operate. This energy cost must be weighed against the energy value of the products you create.

A process might be technically effective at producing syngas but economically unviable if the energy required to run the reactor is too high.

Making the Right Choice for Your Goal

Select your parameters based on a clear understanding of your desired end product.

- If your primary focus is high-quality biochar: Use slow pyrolysis with lower temperatures (400-500°C) and long residence times (hours).

- If your primary focus is liquid bio-oil: Use fast pyrolysis with moderate temperatures (500-650°C) and very short residence times (seconds).

- If your primary focus is flammable syngas: Use fast or flash pyrolysis with high temperatures (>700°C) to maximize thermal cracking.

Ultimately, mastering pyrolysis is about understanding how to manipulate temperature and time to create precisely the product you need.

Summary Table:

| Target Product | Optimal Temperature Range | Optimal Residence Time | Pyrolysis Type |

|---|---|---|---|

| Biochar (Solid) | 400°C - 500°C | Hours | Slow Pyrolysis |

| Bio-oil (Liquid) | 500°C - 700°C | Seconds | Fast Pyrolysis |

| Syngas (Gas) | >700°C | Seconds | Fast/Flash Pyrolysis |

Ready to optimize your pyrolysis process?

The right lab equipment is critical for precise temperature and time control to achieve your target product yields. KINTEK specializes in high-quality pyrolysis reactors and laboratory systems designed for researchers and engineers working with biomass, plastics, and other feedstocks.

Contact our experts today to discuss how our solutions can help you master your pyrolysis parameters and enhance your research or production efficiency.

Visual Guide

Related Products

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory High Pressure Vacuum Tube Furnace

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

People Also Ask

- What are the parts of a carbon regeneration kiln? A Guide to Its Core Components and Function

- How is biochar made from pyrolysis? Unlock the secrets of turning biomass into valuable carbon

- What is the thermal regeneration process of activated carbon? Restore Performance and Cut Costs

- How many degrees is the rotary kiln heated? Unlock the Key to Your Process Temperature

- What are the advantages of catalytic pyrolysis over thermal pyrolysis? Achieve Higher-Quality Bio-Oil and Chemicals

- What is a carbon regeneration kiln? Reuse Spent Carbon to Cut Costs & Waste

- What factors are considered when determining the size of a rotary kiln? Expert Sizing Guide for Efficiency

- What is the temperature of regeneration? Optimize Your Desiccant System's Efficiency