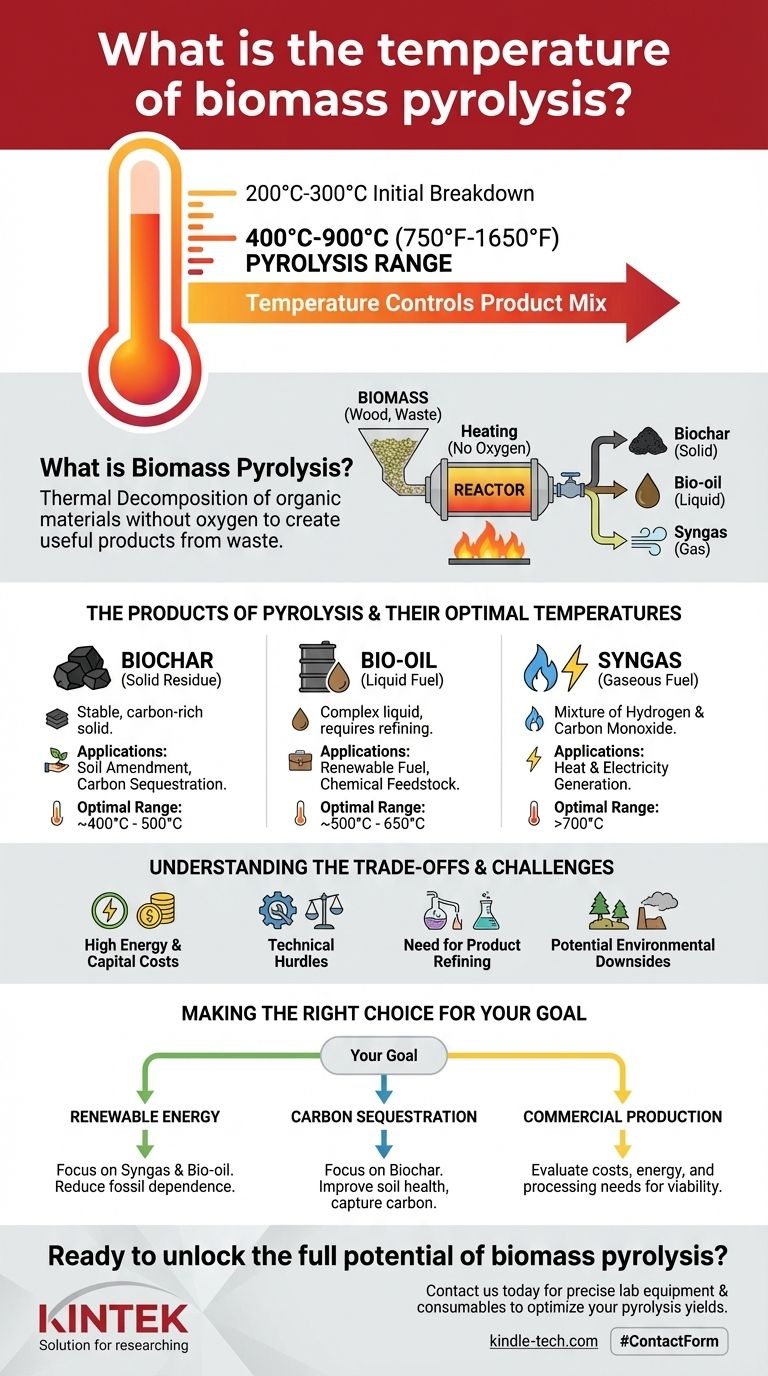

The temperature for biomass pyrolysis is a controlled variable, not a single fixed number. The process typically occurs in a range between 400°C and 900°C (750°F to 1650°F), though the initial breakdown of materials like wood can begin at temperatures as low as 200°C to 300°C.

Understanding pyrolysis temperature is not about finding one correct number. It's about recognizing that temperature is the primary control lever used to determine the final mix of valuable products—bio-oil, biochar, and syngas—derived from the biomass.

What is Biomass Pyrolysis?

A Process of Thermal Decomposition

Biomass pyrolysis is a method of heating organic materials, such as wood, agricultural waste, or other plant-based matter, in the near-total absence of oxygen.

This process prevents combustion and instead causes the material to thermally decompose into a mixture of solid, liquid, and gas products.

The Goal: Transforming Waste into Value

The primary purpose of pyrolysis is to convert low-value or waste biomass into useful and valuable materials.

These outputs, such as biofuels and industrial chemicals, serve as renewable alternatives to fossil fuels and contribute to a more circular economy.

The Products of Pyrolysis

Biochar: The Solid Residue

Biochar is a stable, charcoal-like solid rich in carbon. It is primarily used as a soil amendment to improve fertility and as a method for long-term carbon sequestration, effectively locking carbon away in the ground.

Bio-oil: The Liquid Fuel

Also known as pyrolysis oil, this liquid is a complex mixture of organic compounds. While it requires further refining before it can be used as a transportation fuel, it serves as a valuable chemical feedstock and a renewable fuel source.

Syngas: The Gaseous Fuel

Syngas is a mixture of combustible gases, primarily hydrogen and carbon monoxide. It can be burned directly to generate heat and electricity, contributing to renewable energy production.

Understanding the Trade-offs and Challenges

High Energy and Capital Costs

A significant weakness of biomass pyrolysis is its high energy consumption needed to reach and maintain the required temperatures. The capital cost for building and operating a pyrolysis facility is also substantial.

Technical and Operational Hurdles

Scaling the process from a lab to an industrial level presents technical difficulties. Furthermore, the variability of biomass feedstock can affect the consistency and quality of the final products, creating operational challenges.

The Need for Product Refining

The outputs of pyrolysis are not always ready for immediate use. For example, bio-oil must be separated, purified, and upgraded before it can effectively replace conventional fuels, adding another layer of cost and complexity.

Potential Environmental Downsides

While often beneficial, the environmental impact depends heavily on execution. If the biomass is sourced unsustainably, it can lead to deforestation. A poorly controlled process can also release pollutants like particulate matter and volatile organic compounds.

Making the Right Choice for Your Goal

The specific application of biomass pyrolysis depends entirely on balancing its benefits with its inherent challenges.

- If your primary focus is renewable energy: Pyrolysis is a powerful tool for generating syngas and bio-oil, reducing dependence on fossil fuels.

- If your primary focus is carbon sequestration: The production of biochar offers a direct and stable method for capturing carbon and improving soil health.

- If your primary focus is commercial production: You must carefully evaluate the high capital costs, energy inputs, and the need for downstream processing to ensure economic viability.

Ultimately, mastering biomass pyrolysis means using temperature as a precise instrument to unlock the specific value chain you aim to create.

Summary Table:

| Pyrolysis Temperature Range | Primary Product | Key Application |

|---|---|---|

| ~400°C - 500°C | Biochar | Soil amendment, carbon sequestration |

| ~500°C - 650°C | Bio-oil | Renewable fuel, chemical feedstock |

| >700°C | Syngas | Heat and electricity generation |

Ready to unlock the full potential of biomass pyrolysis in your lab or facility?

KINTEK specializes in providing the precise, high-quality lab equipment and consumables you need to accurately control pyrolysis temperatures and optimize your product yields. Whether you're developing renewable energy solutions, advancing carbon sequestration research, or scaling up commercial production, our expertise and reliable products are here to support your success.

Contact us today using the form below to discuss how we can help you achieve your specific pyrolysis goals. Let's transform your biomass into value together!

Visual Guide

Related Products

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Calciner Small Rotary Kiln Rotating Furnace

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What are the types of pyrolysis reactors used in industry? Choose the Right Technology for Your Product

- What is the difference between calcining and roasting? A Guide to High-Temperature Processing

- What is the principle of rotary kiln? Mastering Continuous Thermal Processing

- What are the zones in rotary kiln in cement production? Master the Core Process for High-Quality Clinker

- What equipment is used in pyrolysis? Choosing the Right Reactor for Your Feedstock and Products