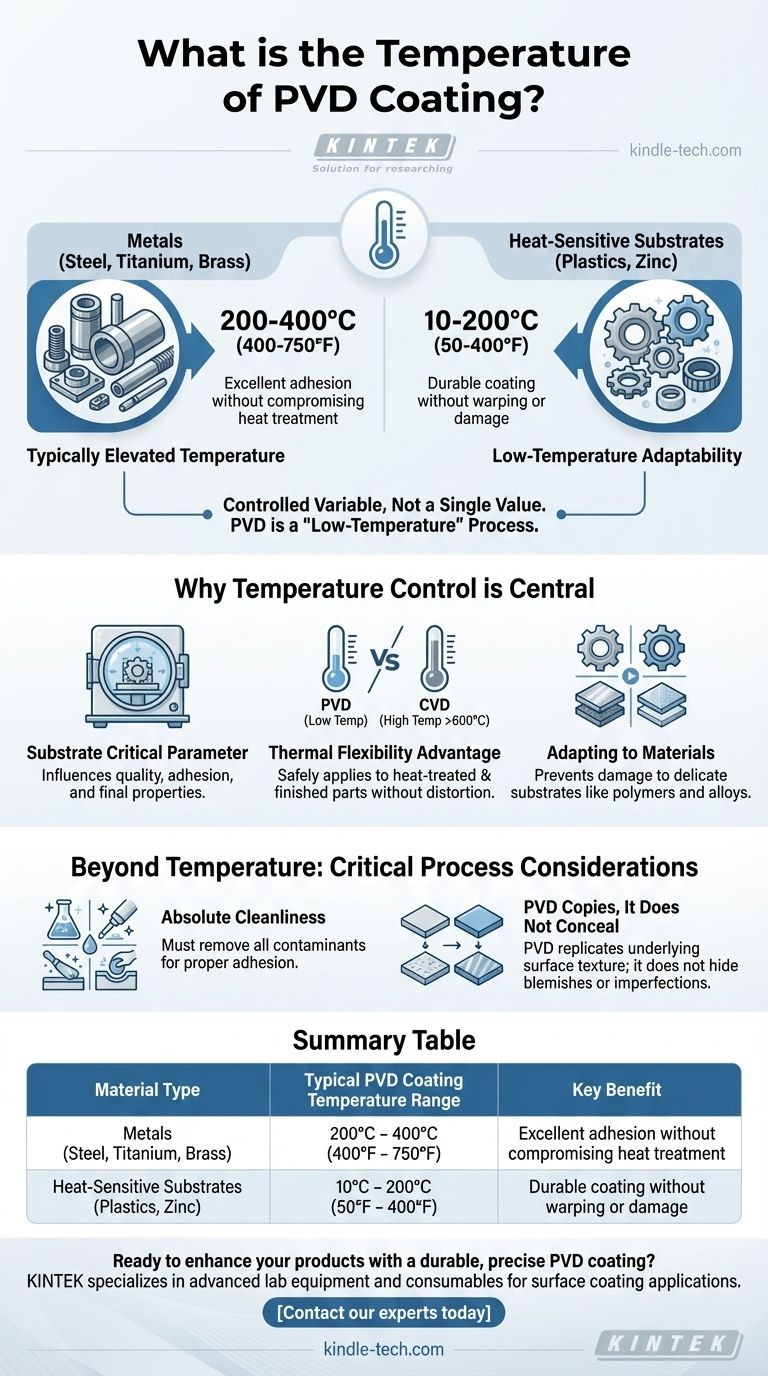

The temperature of a PVD coating process is not a single value but a controlled variable that depends heavily on the material being coated. Typically, the process temperature for metals like steel or brass is in the range of 200-400°C (approximately 400-750°F). For more heat-sensitive substrates, such as plastics or zinc alloys, the temperature can be adjusted to be significantly lower, from near room temperature up to 200°C (50-400°F).

The key takeaway is that Physical Vapor Deposition (PVD) is fundamentally a "low-temperature" coating process. This thermal flexibility is one of its primary advantages, allowing it to enhance a wide variety of materials without altering their underlying structural properties.

Why Temperature Control is Central to PVD

The temperature of the substrate (the part being coated) is a critical parameter that directly influences the quality, adhesion, and final properties of the PVD coating. It's a carefully balanced variable in the vacuum deposition chamber.

The Typical Range for Metals

For most common industrial applications involving steel, titanium, or brass, the process is run between 200°C and 400°C.

This elevated temperature promotes better adhesion of the coating to the substrate and helps achieve the desired coating density and hardness.

Adapting for Heat-Sensitive Substrates

A key strength of PVD is its adaptability. For materials that cannot withstand high heat, like polymers (plastics) or certain metal alloys like zinc, the process can be run at much lower temperatures.

This can range from 10°C to 200°C (50°F to 400°F), preventing any damage, warping, or compromising of the part's integrity.

The Advantage Over High-Temperature Methods

This controlled, relatively low temperature profile is a distinct advantage over other processes like Chemical Vapor Deposition (CVD), which often requires temperatures exceeding 600°C.

PVD's lower heat input means it can be safely applied to finished, heat-treated, and precision-machined parts without causing distortion or changing the material's temper.

Beyond Temperature: Critical Process Considerations

While temperature is a vital parameter, it is only one piece of the puzzle. Achieving a successful PVD coating requires a holistic understanding of the entire process, especially surface preparation.

The Necessity of Absolute Cleanliness

Before entering the coating chamber, parts must be meticulously cleaned. The process must remove all contaminants, including oxides, organic films, and any residue from prior machining.

Techniques like acid etching, sandblasting, or polishing are used to create a pristine surface, which is essential for proper coating adhesion.

PVD Copies, It Does Not Conceal

It is crucial to understand that PVD is a thin-film coating that perfectly replicates the underlying surface texture. It does not level, fill, or hide scratches, blemishes, or imperfections.

If you desire a polished, mirror-like PVD finish, the part must be polished to a mirror finish before it is coated. Likewise, a brushed or satin finish must be applied to the substrate first to achieve a matte PVD result.

Making the Right Choice for Your Material

Understanding the temperature requirements helps you determine if PVD is the correct choice for your specific application.

- If your primary focus is coating high-tolerance steel or titanium parts: PVD is an excellent choice, as its temperature range is safely below the point where it would alter the material's heat treatment or dimensions.

- If your primary focus is adding a durable coating to plastics or zinc: PVD's ability to operate at very low temperatures makes it one of the few high-performance coating options available for these heat-sensitive materials.

- If your primary focus is achieving a flawless aesthetic finish: Your attention must be on the pre-coating surface preparation, as the PVD layer will only mirror the quality of the surface it is applied to.

Ultimately, the controlled temperature of the PVD process makes it an exceptionally versatile and precise tool for enhancing the durability and performance of a vast array of products.

Summary Table:

| Material Type | Typical PVD Coating Temperature Range | Key Benefit |

|---|---|---|

| Metals (Steel, Titanium, Brass) | 200°C - 400°C (400°F - 750°F) | Excellent adhesion without compromising heat treatment |

| Heat-Sensitive Substrates (Plastics, Zinc) | 10°C - 200°C (50°F - 400°F) | Durable coating without warping or damage |

Ready to enhance your products with a durable, precise PVD coating?

KINTEK specializes in providing advanced lab equipment and consumables for surface coating applications. Whether you are working with high-tolerance metals or delicate plastics, our solutions can help you achieve superior coating results.

Contact our experts today to discuss how we can support your laboratory's specific coating needs and help you leverage the full versatility of PVD technology.

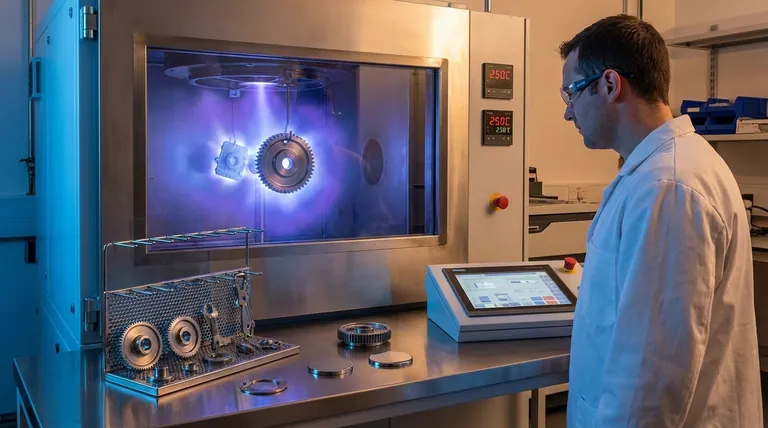

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Lab Plastic PVC Calender Stretch Film Casting Machine for Film Testing

- Touchscreen Automatic Vacuum Heat Press

- Lab Blown Film Extrusion Three Layer Co-Extrusion Film Blowing Machine

People Also Ask

- What is the RF frequency for sputtering? Unlocking the Standard for Insulating Materials

- What is deposition in environmental chemistry? Understanding How Air Pollution Harms Ecosystems

- What are the effects of magnetron sputtering? Achieve High-Quality, Durable Thin Films for Your Lab

- What does PVD sputtering mean? A Guide to High-Performance Thin Film Deposition

- What is a sputtering system? Achieve Unmatched Thin Film Deposition for Your Lab