In practice, the temperature of pyrolysis products corresponds directly to the temperature of the process that created them, typically ranging from 400°C to over 900°C. These products exit the reactor extremely hot and require controlled cooling. However, the more critical question is not their exit temperature, but how the chosen process temperature fundamentally dictates which products are formed in the first place.

The core principle of pyrolysis is that temperature, combined with heating rate, acts as a control dial. Lower temperatures primarily yield solid biochar, high temperatures produce combustible gases, and a carefully controlled middle range optimizes for liquid bio-oil.

How Temperature Dictates Pyrolysis Outcomes

Pyrolysis is not a single process but a spectrum of thermal decomposition. By adjusting the temperature inside the reactor, you are essentially choosing whether to prioritize the creation of solids, liquids, or gases from the initial feedstock.

Low-Temperature Pyrolysis (< 450°C): Maximizing Biochar

At lower temperatures, typically below 450°C, and combined with slow heating rates, the decomposition process is less severe.

This environment favors the formation of biochar, a stable, carbon-rich solid. The molecular structures of the biomass don't have enough energy to break down completely into volatile gases and liquids, leaving behind a solid "skeleton."

Moderate-Temperature Pyrolysis (approx. 450-800°C): Optimizing for Bio-oil

This is the range most often associated with "fast pyrolysis," where the goal is to create liquid fuel.

At these intermediate temperatures and with relatively high heating rates, biomass breaks down rapidly into vapors and aerosols. When these are cooled and condensed quickly, they form bio-oil (also called pyrolysis oil or tar).

High-Temperature Pyrolysis (> 800°C): Prioritizing Gas Production

When temperatures exceed 800°C, the thermal cracking process is intense and extensive. This is often called gasification.

At such high energy levels, larger organic molecules are completely broken down into the simplest, most stable gaseous compounds. This process maximizes the yield of syngas (synthesis gas), a mixture of combustible gases like hydrogen and carbon monoxide, which can be used to generate heat and power.

Understanding the Trade-offs: The Critical Role of Heating Rate

Temperature is the primary driver, but the speed at which the feedstock reaches that temperature—the heating rate—is a crucial secondary control that works in tandem with it.

Slow Heating: The Path to Stable Solids

A slow heating rate gives volatile components time to escape gradually while allowing the remaining carbon structure to rearrange and stabilize.

This is why slow pyrolysis at low temperatures is the ideal pathway for producing high-quality biochar for agriculture or as a solid fuel.

Rapid Heating: The Key to Liquids and Gases

A rapid heating rate shocks the feedstock, causing its components to vaporize instantly before they have a chance to form into stable char.

This rapid vaporization is essential for maximizing the yield of bio-oil in the moderate temperature range. At very high temperatures, this same rapid heating ensures the complete breakdown into syngas.

Making the Right Choice for Your Goal

The optimal pyrolysis temperature is determined entirely by your desired end product. Once produced, all products will be extremely hot and must be handled by appropriate collection and cooling systems, such as water-cooling dischargers for charcoal or condensers for liquids.

- If your primary focus is soil amendment or solid fuel: Target low temperatures (< 450°C) with a slow heating rate to maximize biochar yield.

- If your primary focus is creating a liquid fuel alternative: Use moderate temperatures with a rapid heating rate to optimize the production of bio-oil.

- If your primary focus is generating syngas for energy: Employ high temperatures (> 800°C) with a rapid heating rate to ensure complete conversion to gas.

Ultimately, controlling the thermal environment inside the reactor gives you precise control over the final product slate.

Summary Table:

| Desired Product | Optimal Temperature Range | Key Process Focus |

|---|---|---|

| Biochar (Solid) | < 450°C | Slow pyrolysis, slow heating rate |

| Bio-Oil (Liquid) | 450°C - 800°C | Fast pyrolysis, rapid heating rate |

| Syngas (Gas) | > 800°C | Gasification, rapid heating rate |

Ready to optimize your pyrolysis process for maximum yield?

The right equipment is crucial for precisely controlling temperature and heating rate to achieve your target product. KINTEK specializes in high-quality lab reactors and pyrolysis systems designed for reliable performance and precise thermal control.

Contact our experts today to discuss how our solutions can help you efficiently produce biochar, bio-oil, or syngas for your specific application.

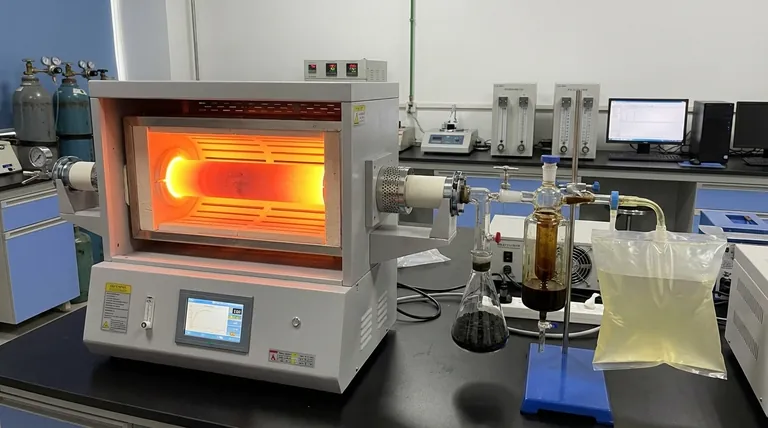

Visual Guide

Related Products

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vertical Laboratory Tube Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Rotary Tube Furnace Split Multi Heating Zone Rotating Tube Furnace

People Also Ask

- Why is a horizontal alumina tube furnace ideal for mixed gas corrosion at 650 °C? Ensure Pure Experimental Integrity

- What is the ceramic tube high temperature? From 1100°C to 1800°C, Choose the Right Material

- Why is an Alumina Ceramic Tube Support Necessary for 1100°C Experiments? Ensure Data Accuracy and Chemical Inertness

- How do I choose a tube furnace? A Guide to Matching Your Process Needs

- What tube is used for tubular furnace? Choose the Right Material for Temperature & Atmosphere