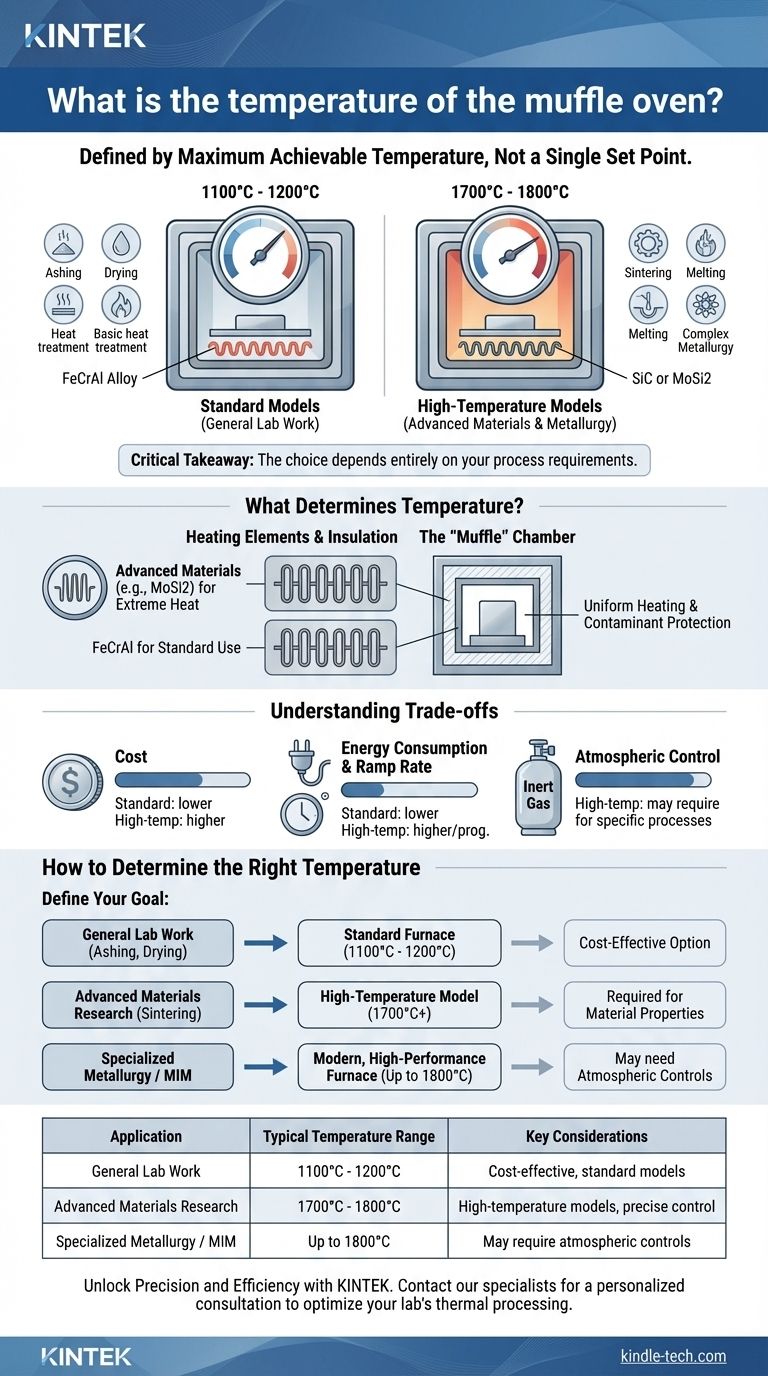

A muffle furnace does not have a single set temperature. Instead, these devices are defined by their maximum achievable temperature, which varies significantly based on the model and its intended application. While standard laboratory furnaces typically operate up to 1100°C or 1200°C, advanced models designed for specialized metallurgy and materials science can reach temperatures as high as 1800°C (3272°F).

The critical takeaway is not the furnace's temperature, but the temperature your specific process requires. The choice of furnace is dictated entirely by the material you are working with and the thermal process you need to perform, such as ashing, sintering, or heat-treating.

What Determines a Muffle Furnace's Temperature?

The wide range of temperatures cited for muffle furnaces reflects the diversity of their design and purpose. The maximum temperature is not an arbitrary number but a result of specific engineering choices.

Standard vs. High-Temperature Models

Most muffle furnaces fall into two broad categories. Standard models, common in general-purpose labs, typically reach a maximum temperature of 1100°C to 1200°C. These are ideal for routine applications like ashing, drying, and basic metal heat treatment.

High-temperature models are built for more demanding industrial and research applications. These furnaces can reach 1700°C to 1800°C, enabling advanced processes like ceramic sintering, glass melting, and complex metallurgy.

The Role of Heating Elements and Insulation

The primary factor dictating a furnace's temperature limit is the material used for its heating elements and insulation.

Standard furnaces often use iron-chromium-aluminum (FeCrAl) alloy elements. High-temperature models require more exotic and durable materials, such as silicon carbide (SiC) or molybdenum disilicide (MoSi2), to withstand the extreme heat without degrading.

The "Muffle" and Uniform Heating

The defining feature of a muffle furnace is the "muffle"—an insulating chamber that separates the material being heated from the heating elements. This design ensures exceptionally uniform temperature distribution and protects the sample from any contaminants produced by the heat source, which is critical for precise and repeatable results.

Understanding the Trade-offs

Choosing a furnace involves more than just selecting the highest possible temperature. Higher performance comes with significant trade-offs that must be considered.

Cost vs. Capability

The most significant trade-off is cost. The advanced materials and engineering required for a furnace to safely and reliably reach 1800°C make it substantially more expensive than a standard 1200°C model. Over-specifying a furnace for a low-temperature application is an unnecessary expense.

Energy Consumption and Ramp Rate

Higher maximum temperatures require significantly more power. Furthermore, the time it takes to heat up to the target temperature (the "ramp rate") and cool down can be a critical process parameter. High-performance furnaces often have programmable controllers to manage these rates precisely.

Atmospheric Control

For certain advanced applications, such as debinding in metal injection molding, temperature is not the only variable. These processes may require a controlled atmosphere (e.g., inert gas like argon) to prevent oxidation. This adds another layer of complexity and cost to the furnace system.

How to Determine the Right Temperature

The correct furnace temperature is the one that meets the requirements of your specific process. To make the right choice, you must first define your goal.

- If your primary focus is general lab work like ashing or sample drying: A standard furnace with a maximum temperature of 1100°C to 1200°C is perfectly suitable and the most cost-effective option.

- If your primary focus is advanced materials research, such as sintering high-performance ceramics: You will likely need a high-temperature model capable of reaching 1700°C or more to achieve the required material properties.

- If your primary focus is specialized metallurgy or metal injection molding (MIM): Your process demands a modern, high-performance furnace that can achieve up to 1800°C and may require sophisticated atmospheric controls.

Ultimately, defining your process requirements is the essential first step to identifying the correct furnace and temperature range for your work.

Summary Table:

| Application | Typical Temperature Range | Key Considerations |

|---|---|---|

| General Lab Work (Ashing, Drying) | 1100°C - 1200°C | Cost-effective, standard models |

| Advanced Materials Research (Sintering) | 1700°C - 1800°C | High-temperature models, precise control |

| Specialized Metallurgy / MIM | Up to 1800°C | May require atmospheric controls |

Unlock Precision and Efficiency in Your Lab

Choosing the right muffle furnace is critical for achieving accurate, repeatable results in your thermal processes. At KINTEK, we specialize in providing high-performance lab equipment tailored to your specific needs—whether you're conducting routine ashing or advanced materials research.

Our experts will help you select a furnace that matches your temperature requirements, budget, and application goals, ensuring optimal performance and longevity.

Ready to optimize your lab's thermal processing? Contact our specialists today for a personalized consultation and discover how KINTEK's solutions can enhance your research and production outcomes.

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is the function of a high-precision annealing furnace for zirconium? Achieving Perfect Equiaxed Grain Structures

- What are the primary functions of a high-temperature muffle furnace in CaO catalyst production? Master Biodiesel Efficiency

- Why is it necessary to perform heat treatment in a muffle furnace after TiO2 nanotube synthesis? Unlock Anatase Power

- What is the difference between a muffle furnace and a blast furnace? Precision vs. Production

- What events occur during sintering? From Powder to Solid in 3 Key Stages

- What is the function of a chamber furnace? Master Precise Thermal Processing for Your Materials

- Why are program-controlled precision ovens and calcination furnaces necessary for Au/CeO2 catalysts? Optimize Activity

- What role does a program-controlled box resistance furnace play in the microstructural control of Al0.6CoCrFeNi/5052Al?