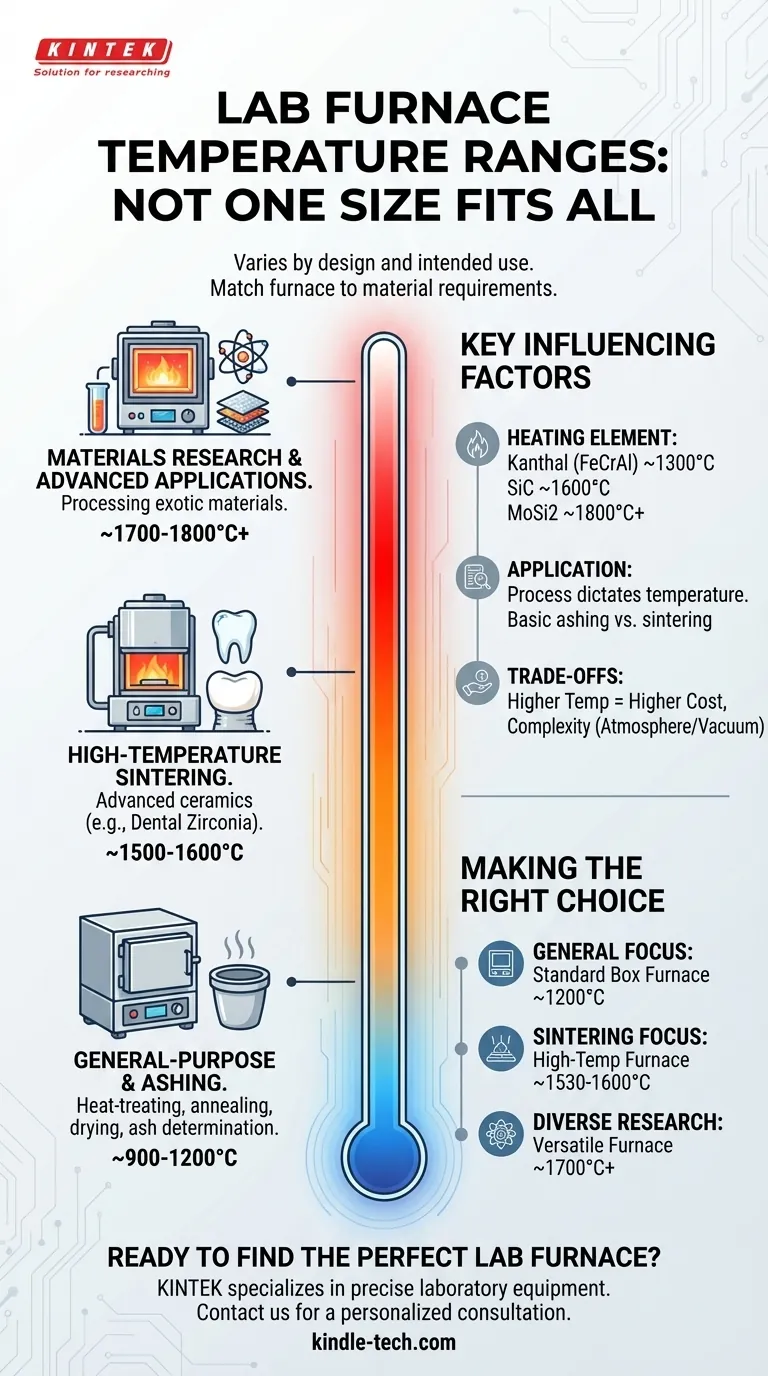

The temperature range of a lab furnace is not a single, defined value; it varies dramatically based on the furnace's specific design and intended use. While general-purpose models operate up to 1100-1200°C (approx. 2000-2200°F), specialized high-temperature units for applications like ceramic sintering can easily exceed 1500°C (2732°F) and go much higher.

A "lab furnace" is a broad category, not a single piece of equipment. The critical task is not to find one generic temperature range, but to match the furnace's maximum temperature and heating technology to the specific material processing requirements of your application.

Why Temperature Ranges Vary So Widely

The maximum attainable temperature in a lab furnace is not an arbitrary number. It is a direct result of the materials used in its construction and the scientific process it was designed to perform.

The Role of the Heating Element

The core of any electric furnace is its heating element, and the material used for this element is the primary limiting factor for its maximum temperature.

- Kanthal (FeCrAl) alloys are common in general-purpose furnaces and typically max out around 1200°C to 1300°C.

- Silicon Carbide (SiC) elements allow for higher operating temperatures, often up to 1600°C.

- Molybdenum Disilicide (MoSi2) elements are used in high-performance furnaces and can achieve temperatures of 1700°C to 1800°C or more.

The Influence of the Application

The process you need to perform dictates the temperature you must achieve. Different scientific and industrial tasks have vastly different thermal requirements.

A furnace for a basic ashing procedure, for example, may only need to reach 900°C. In contrast, processing advanced materials requires much more thermal energy. A dental furnace designed for sintering zirconium oxide must reach temperatures around 1530°C to achieve the material's final strength and translucency.

Common Furnace Types and Their Temperatures

Understanding the main categories of lab furnaces helps clarify the relationship between design and temperature capability.

General-Purpose Box Furnaces

These are the most common type found in laboratories. They are versatile workhorses used for applications like heat-treating, annealing, and drying. Their temperature range is typically between ambient and 1100°C or 1200°C. Some gas-fired models operate in a similar range, reaching up to 1093°C (2000°F).

Ashing Furnaces

Designed specifically for determining the ash content of a sample, these furnaces prioritize airflow to ensure complete combustion. Their temperature requirements are moderate, usually maxing out between 900°C and 1100°C.

High-Temperature (Sintering) Furnaces

These are specialized units built for processing ceramics, metals, and other advanced materials. They use high-performance heating elements (like SiC or MoSi2) and advanced insulation to safely reach and hold temperatures from 1500°C to 1800°C and beyond.

Understanding the Trade-offs

Selecting a furnace isn't just about finding the highest temperature. You must consider the practical implications of your choice.

Cost vs. Maximum Temperature

There is a direct and steep correlation between a furnace's maximum temperature and its cost. The exotic materials required for heating elements and insulation in high-temperature models are significantly more expensive. Buying a furnace with a much higher temperature range than you need is an unnecessary expense.

Atmosphere Control

Many high-temperature processes, particularly with metals, cannot be performed in ambient air due to oxidation. These applications require a furnace that can operate with a controlled atmosphere (like argon or nitrogen) or under a vacuum, which adds significant complexity and cost.

Uniformity and Control

Simply reaching a high temperature is not enough; the temperature must be uniform throughout the chamber and precisely controlled. High-end furnaces offer superior controllers and chamber designs to ensure consistent and repeatable results, which is critical for sensitive materials.

Making the Right Choice for Your Application

To select the right equipment, focus on the needs of your material and process first.

- If your primary focus is general heat treating, drying, or ashing: A standard box furnace with a maximum temperature of 1200°C is typically sufficient and cost-effective.

- If your primary focus is sintering advanced ceramics like zirconium oxide: You will require a dedicated high-temperature furnace capable of reaching at least 1530°C to 1600°C.

- If your primary focus is materials research with diverse requirements: Consider a more versatile furnace with a 1700°C range and optional atmosphere control to ensure future compatibility.

Ultimately, defining your material's specific processing window is the most critical step in selecting the correct lab furnace.

Summary Table:

| Furnace Type | Typical Max Temperature | Key Applications |

|---|---|---|

| General-Purpose Box Furnace | 1100-1200°C | Heat-treating, annealing, drying |

| Ashing Furnace | 900-1100°C | Ash content determination |

| High-Temperature Sintering Furnace | 1500-1800°C+ | Ceramic sintering, materials research |

Ready to find the perfect lab furnace for your specific temperature needs?

At KINTEK, we specialize in providing precise laboratory equipment and consumables tailored to your unique requirements. Whether you need a standard box furnace for general heat treatment or a high-temperature sintering furnace for advanced ceramics, our experts will help you select the right solution to ensure accurate, repeatable results.

Don't compromise on your research or production quality. Contact us today for a personalized consultation and let KINTEK be your trusted partner in laboratory excellence.

Visual Guide

Related Products

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- Vertical Laboratory Tube Furnace

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

People Also Ask

- What materials are used for the tubes in tube furnaces? A Guide to Selecting the Right Tube for Your Process

- What precautions should be taken when using a tube furnace? Ensure Safe, Effective High-Temperature Processing

- How does a quartz tube vacuum furnace contribute to the crystallization process of Ag-doped Li-argyrodite electrolytes?

- Why is a quartz tube furnace utilized in the thermal oxidation of MnCr2O4 coatings? Unlock Precise Selective Oxidation

- What role does a quartz tube furnace play in hBN synthesis? Optimize Your Chemical Vapor Deposition Results