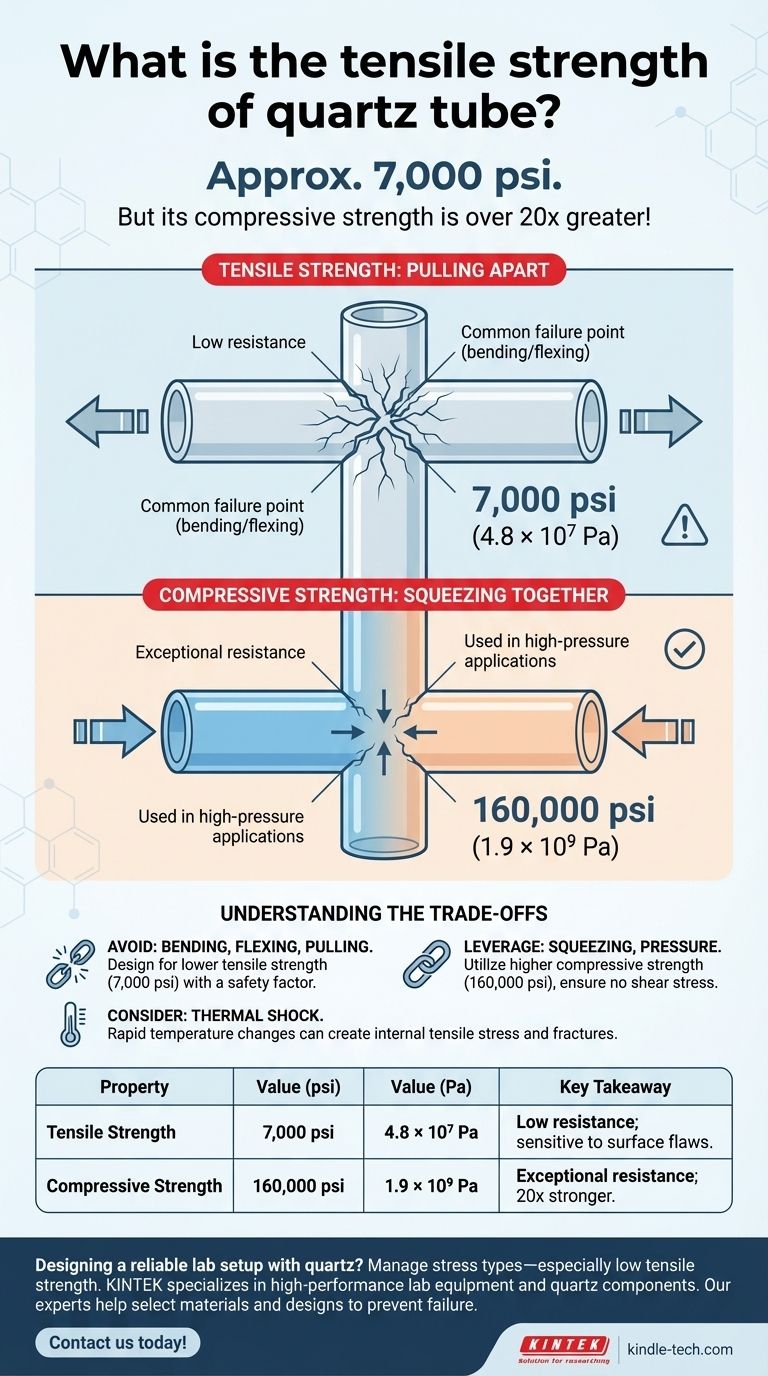

The short answer is approximately 7,000 psi. A standard fused quartz tube, such as one made from GE 124, has a tensile strength of about 4.8 x 10^7 Pascals, which converts to 7,000 pounds per square inch (psi). However, this number only tells part of the story, as the true strength of quartz in any application depends heavily on how it is being used.

While quartz has a specific tensile strength, its most important mechanical property is its immense compressive strength. Understanding the difference is critical for using quartz effectively and avoiding catastrophic failure.

The Two Sides of Strength: Tension vs. Compression

When we discuss the "strength" of a material, it's crucial to specify the type of force being applied. For a brittle ceramic-like material such as quartz, the difference is dramatic.

Tensile Strength: Pulling It Apart

Tensile strength measures a material's resistance to being pulled apart. This is the 7,000 psi (4.8 x 10^7 Pa) value.

Imagine pulling on both ends of a quartz rod. Its tensile strength is the maximum pulling force it can withstand before snapping.

For a brittle material like quartz, this value is relatively low. Microscopic surface flaws, cracks, or scratches can act as stress concentrators, providing a starting point for a fracture to propagate when the material is under tension.

Compressive Strength: Squeezing It Together

Compressive strength measures a material's resistance to being squeezed or crushed. For quartz, this value is 160,000 psi (1.9 x 10^9 Pa).

This number is more than 20 times greater than its tensile strength. When quartz is compressed, any existing micro-cracks on its surface are pushed closed, preventing them from spreading and making the material exceptionally strong under these conditions.

Understanding the Trade-offs

The key takeaway is that quartz is not a universally "strong" material in the way steel is. Its performance is highly dependent on the application and the type of stress it will endure.

Why Tensile Strength is a Critical Weakness

The low tensile strength is the most common failure point for quartz components. Any force that causes the material to bend, flex, or stretch can easily exceed its limits.

This is why dropping a quartz tube causes it to shatter. The impact creates bending forces, putting one side of the tube under tension, which immediately leads to a fracture.

Leveraging Compressive Strength

In contrast, applications that place quartz under pure compression can take advantage of its incredible resilience. This is why quartz is used in high-pressure windows and specialized industrial components.

Designing a system to ensure the quartz component remains under compression is the most effective way to ensure its structural integrity.

Making the Right Choice for Your Application

To properly design with quartz, you must analyze the forces your component will experience.

- If your application involves any bending, flexing, or pulling forces: You must design around the lower tensile strength of 7,000 psi and incorporate a significant safety factor.

- If your application involves primarily squeezing or pressure forces: You can leverage the much higher compressive strength of 160,000 psi, but you must ensure no tensile or shear stresses are inadvertently introduced.

- If you are concerned about thermal shock: Rapid temperature changes can create internal tensile stresses that cause fractures, which is a common failure mode unrelated to external mechanical loads.

Ultimately, knowing how quartz will be stressed is far more important than knowing a single strength value.

Summary Table:

| Property | Value (psi) | Value (Pa) | Key Takeaway |

|---|---|---|---|

| Tensile Strength | 7,000 psi | 4.8 × 10^7 Pa | Low resistance to pulling/bending forces; sensitive to surface flaws. |

| Compressive Strength | 160,000 psi | 1.9 × 10^9 Pa | Exceptional resistance to squeezing/crushing forces; 20x stronger than tensile strength. |

Designing a reliable lab setup with quartz components? The key to success is understanding and managing stress types—especially the low tensile strength of quartz. At KINTEK, we specialize in providing high-performance lab equipment and consumables, including quartz tubes designed for specific mechanical and thermal stresses. Our experts can help you select the right materials and designs to prevent failure and ensure long-term durability. Contact us today to discuss your application needs and leverage our expertise for a safer, more efficient laboratory. Get in touch with our specialists

Visual Guide

Related Products

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- Laboratory High Pressure Vacuum Tube Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

People Also Ask

- What are the functional requirements for graphite molds used in B4C/Al sintering? Optimize High-Pressure Performance

- Why are polyurethane milling jars and corundum balls used for boron carbide? Ensure Purity in Advanced Ceramic Mixing

- How does a vacuum drying oven contribute to Ag-SnO2-Y2O3 powder prep? Preserve Purity and Prevent Silver Oxidation

- What are the applicable sample dimensions for the sample holder? Ensure a Perfect Fit for Your Lab Samples

- Why is a constant temperature drying oven used in the pretreatment of aluminum alloy substrates for film preparation?

- When is it more cost-effective to use a single-stage rotary vane pump? Save 50% on Rough Vacuum Costs

- What grinding consumables are recommended for transition metal borides? Achieve High-Purity Micron Powders

- What are the advantages of high-purity quartz reaction tubes compared to metal? Ensure Data Integrity in Lab Research