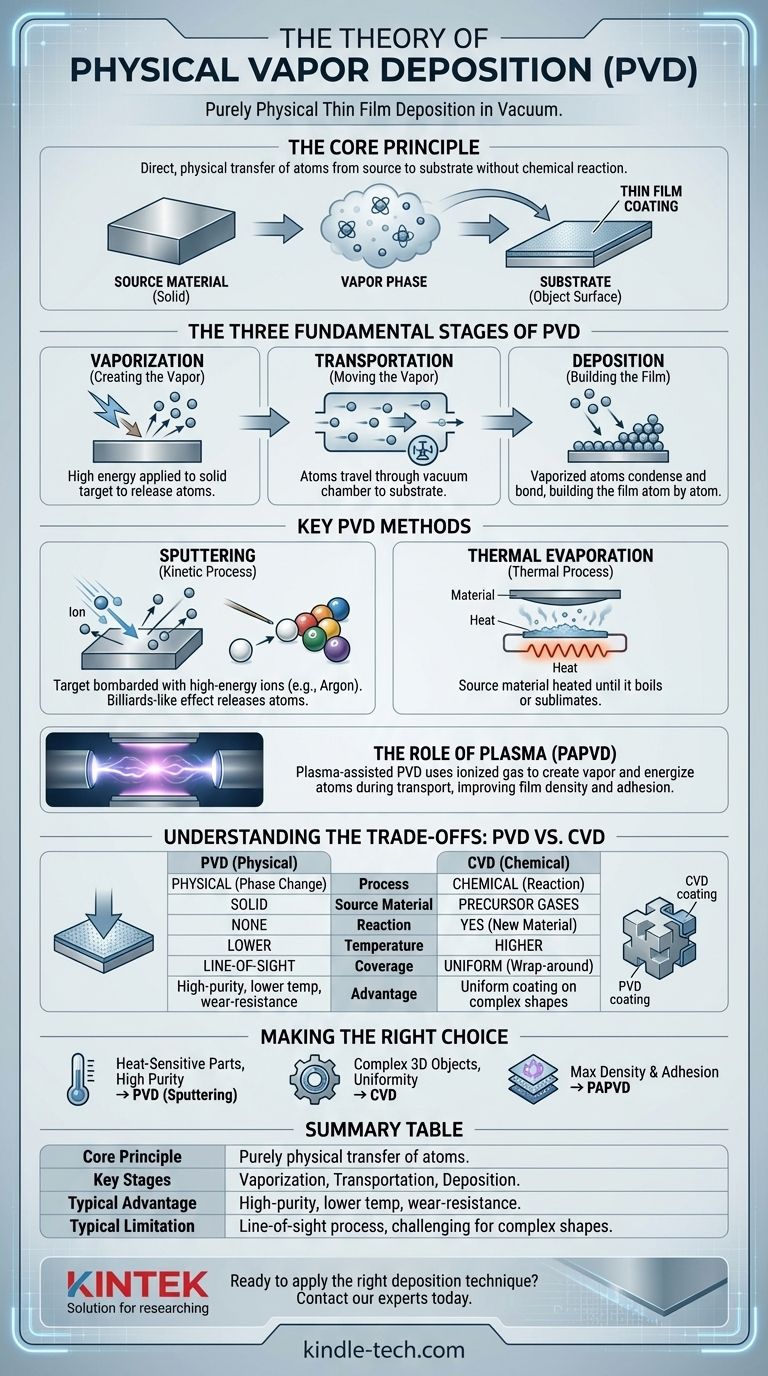

At its core, the theory of Physical Vapor Deposition (PVD) describes a family of processes that create thin films and coatings by purely physical means. The process involves taking a solid material, turning it into a vapor in a vacuum, and then allowing that vapor to condense onto the surface of an object (the substrate). This is fundamentally a phase change process, similar to water evaporating and condensing as dew, but performed with solid materials in a highly controlled environment.

Physical Vapor Deposition is not a single method but a category of vacuum-based techniques. Its unifying theory is the direct, physical transfer of atoms from a source to a substrate, creating a high-performance coating without initiating a chemical reaction on the target surface.

The Three Fundamental Stages of PVD

Every PVD process, regardless of the specific technology used, can be broken down into three essential stages. Understanding this sequence is key to grasping the core theory.

Stage 1: Vaporization (Creating the Vapor)

The first step is to generate a vapor from the source material, often called the "target." This is accomplished by supplying a large amount of energy to the solid material.

The two primary methods for this are sputtering and thermal evaporation.

Stage 2: Transportation (Moving the Vapor)

Once the atoms are liberated from the source material, they travel through a vacuum chamber toward the substrate.

The vacuum is critical. It removes other atoms and molecules (like oxygen and nitrogen) that could collide with the vaporized material, cause contamination, or impede its path to the substrate.

Stage 3: Deposition (Building the Film)

In the final stage, the vaporized atoms arrive at the substrate's surface, where they cool, condense, and bond.

This process builds up, atom by atom, to form a thin, solid film. The properties of this film—its density, adhesion, and structure—are heavily influenced by the energy of the arriving atoms and the condition of the substrate.

Key PVD Methods Explained

The different "types" of PVD are distinguished primarily by how they achieve the first stage: vaporization.

Sputtering

Sputtering is a kinetic process. The target material is bombarded with high-energy ions (typically from an inert gas like Argon) that are accelerated in a plasma environment.

Think of it as a microscopic game of billiards. The incoming ions act like cue balls, striking the atoms of the target material and knocking them loose with enough energy to enter the vapor phase.

Thermal Evaporation

Thermal evaporation is a simpler concept. The source material is heated in the vacuum chamber until it begins to boil or sublimate, releasing a vapor.

This is often done by passing a high electrical current through a resistive element holding the material. It is effective but offers less control over the energy of the depositing atoms compared to sputtering.

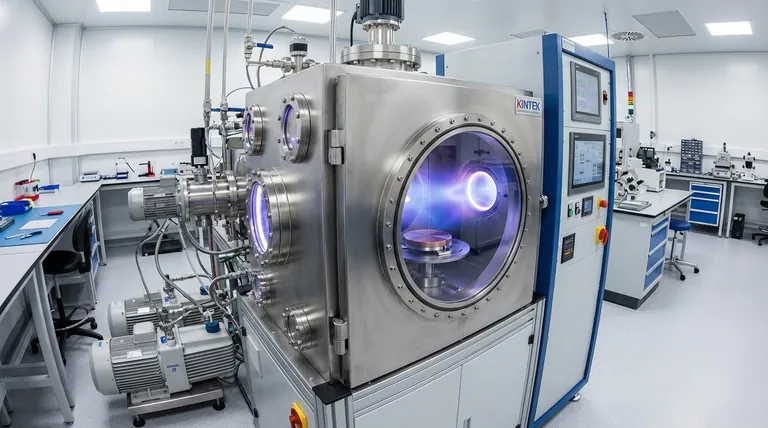

The Role of Plasma (PAPVD)

Many modern PVD systems are plasma-assisted (PAPVD). Plasma, an ionized gas, is used to both create the vapor (as in sputtering) and to energize the atoms during transport.

Bombarding the substrate with ions just before and during deposition can clean the surface and give the condensing atoms more energy. This results in a denser, more uniform, and more strongly bonded coating.

Understanding the Trade-offs: PVD vs. CVD

A common point of confusion is the difference between PVD and Chemical Vapor Deposition (CVD). While both create thin films, their underlying theories are completely different.

The Core Difference: Physical vs. Chemical

As we've seen, PVD is a physical process. The material of the final film is the same as the source material, just transferred from one location to another.

CVD is a chemical process. It introduces precursor gases into a chamber, which then react on the hot surface of the substrate to form a film of an entirely new material. The final film is the product of a chemical reaction.

Temperature and Substrate Compatibility

PVD is generally a lower-temperature process than CVD. This makes PVD suitable for coating materials that cannot withstand high heat, such as plastics or certain metal alloys.

Coverage and Complexity ("Throwing Power")

Because PVD is largely a "line-of-sight" process, where atoms travel in a straight line from the source to the substrate, it can be challenging to coat complex, three-dimensional shapes uniformly.

CVD gases can flow around an object, often resulting in more uniform coverage ("wrap-around") on intricate surfaces.

Making the Right Choice for Your Application

Selecting the correct deposition method requires understanding your end goal.

- If your primary focus is high-purity, wear-resistant coatings on heat-sensitive parts: PVD, particularly sputtering, is often the ideal choice due to its lower processing temperatures and high-energy deposition.

- If your primary focus is achieving a perfectly uniform coating on a complex, 3D object: Chemical Vapor Deposition (CVD) may be more suitable due to its non-directional coating mechanism.

- If your primary focus is maximizing the density and adhesion of your film: Look to plasma-assisted PVD (PAPVD) techniques, which use ion bombardment to dramatically improve film quality.

Understanding these foundational principles allows you to select the precise deposition strategy best suited to your material and performance goals.

Summary Table:

| Key Aspect | Description |

|---|---|

| Core Principle | Purely physical transfer of atoms from a solid source to a substrate in a vacuum. |

| Primary Methods | Sputtering (kinetic) and Thermal Evaporation (thermal). |

| Key Stages | 1. Vaporization 2. Transportation 3. Deposition. |

| Typical Advantage | High-purity, wear-resistant coatings; lower temperature than CVD. |

| Typical Limitation | Line-of-sight process; can be challenging for complex 3D shapes. |

Ready to apply the right deposition technique for your project?

KINTEK specializes in providing advanced lab equipment and consumables for all your thin film coating needs. Whether you are developing new materials, enhancing product durability, or conducting precision research, our expertise in PVD and related technologies can help you achieve superior results.

Contact our experts today to discuss how we can support your laboratory's specific challenges and goals.

Visual Guide

Related Products

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

People Also Ask

- What is microwave plasma CVD? A Guide to High-Purity Diamond and Material Synthesis

- How does a Hot Filament Chemical Vapor Deposition (HFCVD) reactor function? Expert Guide to Diamond Film Fabrication

- How are reactants introduced into the reaction chamber during a CVD process? Mastering Precursor Delivery Systems

- What is the role of the HF-CVD system in preparing BDD electrodes? Scalable Solutions for Boron-Doped Diamond Production

- How is something diamond coated? A Guide to CVD Growth vs. Plating Methods