In essence, Thermal Chemical Vapor Deposition (CVD) is a sophisticated manufacturing process used to create extremely thin, high-performance solid films on a surface. It works by introducing specific gases, called precursors, into a high-temperature vacuum chamber. The heat triggers a chemical reaction, causing the gases to decompose and deposit a solid layer onto a target object, or substrate, effectively "growing" a new material on its surface.

The core principle to understand is that CVD is not a simple painting or dipping process. It is a precise, controlled method for building a material layer-by-layer from a chemical gas, using thermal energy as the catalyst for the transformation.

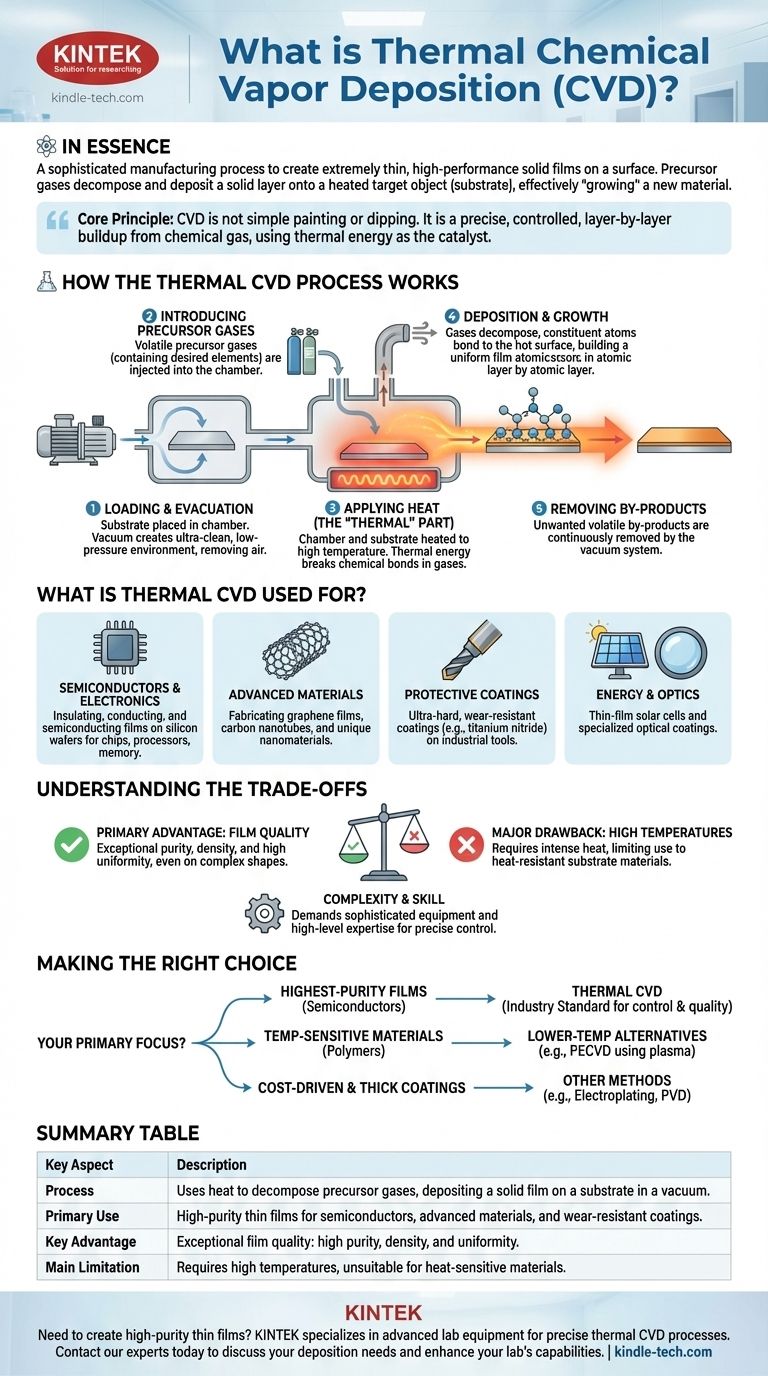

How the Thermal CVD Process Works

To grasp the value of CVD, it's essential to understand its fundamental steps. The entire process occurs within a sealed reaction chamber under carefully controlled conditions.

The Core Components

The system relies on a few key elements: a substrate (the object to be coated), one or more precursor gases (the source chemicals), a reaction chamber, a vacuum system, and a high-temperature heat source.

Step 1: Loading and Evacuation

First, the substrate is placed inside the reaction chamber. The chamber is then sealed, and the vacuum system removes all the air, creating an ultra-clean, low-pressure environment. This prevents contamination from unwanted particles like oxygen or nitrogen.

Step 2: Introducing Precursor Gases

Once the vacuum is stable, one or more volatile precursor gases are precisely injected into the chamber. These gases are chosen specifically because they contain the elements required for the final film (e.g., silicon, carbon, titanium).

Step 3: Applying Heat (The "Thermal" Part)

This is the critical step that defines thermal CVD. The chamber and the substrate within it are heated to a specific, high reaction temperature. This thermal energy provides the activation energy needed to break the chemical bonds within the precursor gases.

Step 4: Deposition and Growth

As the precursor gases decompose near the hot substrate, their constituent atoms bond to the surface. This process occurs uniformly across all exposed areas, building up the desired solid film one atomic layer at a time.

Step 5: Removing By-products

The chemical reactions also produce unwanted volatile by-products. These waste gases are continuously removed from the chamber by the vacuum system, ensuring the purity of the growing film.

What is Thermal CVD Used For?

The ability to create exceptionally pure and uniform thin films makes thermal CVD a foundational technology in many high-tech industries.

Semiconductors and Electronics

This is the most common application. CVD is used to deposit various insulating, conducting, and semiconducting films onto silicon wafers, forming the basis of microchips, processors, and memory devices.

Advanced Materials

The process is critical for fabricating cutting-edge materials. It is a leading method for producing large-area graphene films, carbon nanotubes, and other nanomaterials with unique electronic and structural properties.

Protective Coatings

CVD is used to apply ultra-hard, wear-resistant coatings to industrial cutting tools and components. Materials like titanium nitride dramatically increase the lifespan and performance of these parts, protecting them from corrosion and abrasion.

Energy and Optics

The technology is also used in the manufacturing of thin-film solar cells, where photovoltaic materials are deposited onto a substrate like glass. It's also used to create specialized optical coatings.

Understanding the Trade-offs

While powerful, thermal CVD is not the solution for every application. Understanding its advantages and limitations is key to using it effectively.

The Primary Advantage: Film Quality

The main reason to choose CVD is the exceptional quality of the resulting film. The coatings are typically very pure, dense, and highly uniform, even over complex shapes.

The Major Drawback: High Temperatures

The reliance on intense heat is the process's biggest constraint. It means the substrate material must be able to withstand high temperatures without melting, warping, or degrading. This makes it unsuitable for many plastics or low-melting-point metals.

Complexity and Skill

CVD requires sophisticated vacuum and heating equipment. The process demands a high level of expertise to control the gas flows, temperature, and pressure precisely to achieve the desired outcome.

Making the Right Choice for Your Goal

Selecting a deposition method depends entirely on the requirements of your final product.

- If your primary focus is creating the highest-purity films for semiconductors or advanced electronics: Thermal CVD is the industry standard due to its unparalleled control and quality.

- If your primary focus is coating temperature-sensitive materials like polymers or certain metals: You must explore lower-temperature alternatives, such as Plasma-Enhanced CVD (PECVD), which uses plasma instead of just heat to drive the reaction.

- If your primary focus is on thick, simple protective coatings where cost is the main driver: Other methods like electroplating or certain types of Physical Vapor Deposition (PVD) might be more economical.

Ultimately, thermal CVD is a foundational technology for building the high-performance materials that define our modern world.

Summary Table:

| Key Aspect | Description |

|---|---|

| Process | Uses heat to decompose precursor gases, depositing a solid film on a substrate in a vacuum chamber. |

| Primary Use | High-purity thin films for semiconductors, graphene, carbon nanotubes, and wear-resistant coatings. |

| Key Advantage | Exceptional film quality: high purity, density, and uniformity. |

| Main Limitation | Requires high temperatures, limiting use with heat-sensitive materials. |

Need to create high-purity thin films for your research or production? KINTEK specializes in providing advanced lab equipment and consumables for precise thermal CVD processes. Our solutions help laboratories in semiconductor, materials science, and R&D sectors achieve unparalleled film quality and process control. Contact our experts today to discuss how we can support your specific deposition needs and enhance your lab's capabilities.

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- What is the process of vacuum vapor deposition? Mastering CVD and PVD Thin-Film Coating

- How does PECVD work? Enable Low-Temperature, High-Quality Thin Film Deposition

- What are the methods of deposition? A Guide to PVD and CVD Thin-Film Techniques

- What is the difference between PECVD and CVD? Unlock the Right Thin-Film Deposition Method

- What color diamonds are CVD? Understanding the Process from Brown Tint to Colorless Beauty