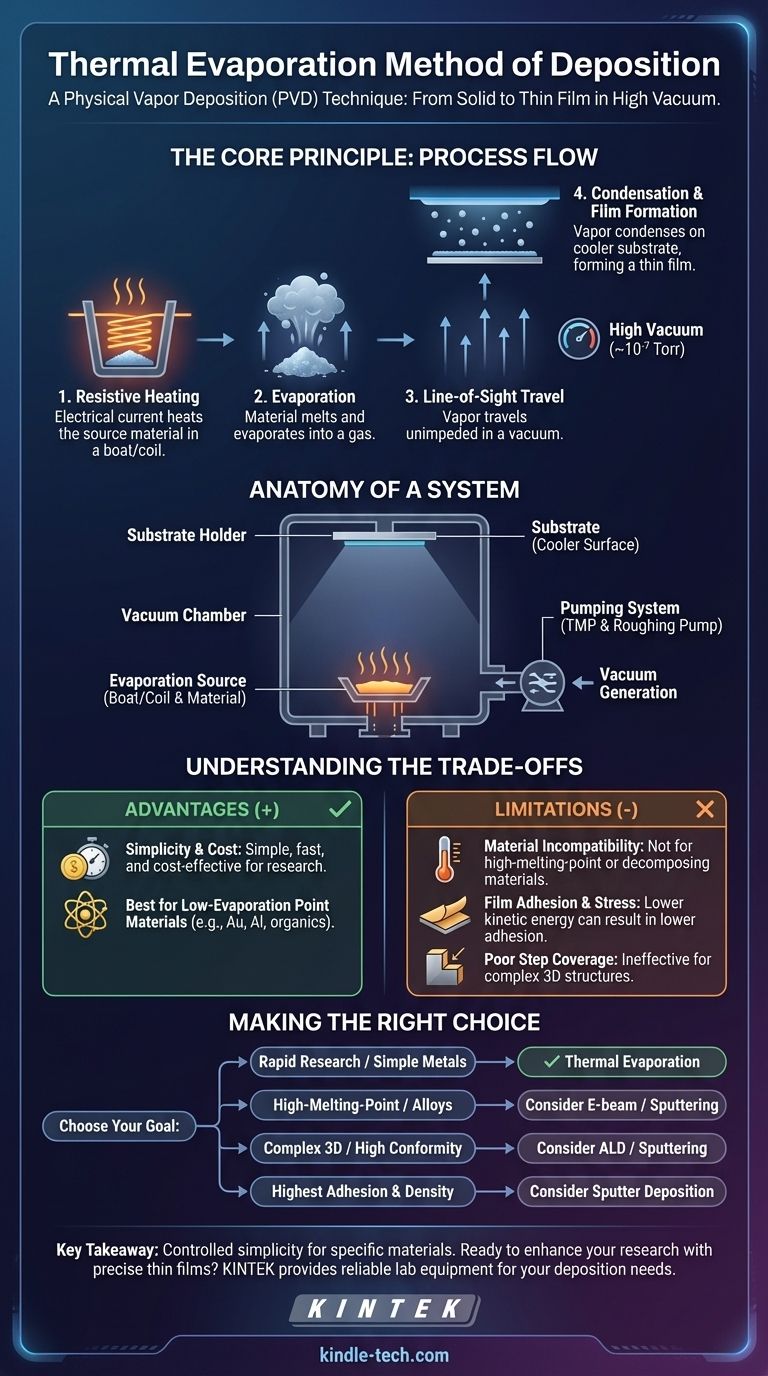

In short, thermal evaporation is a physical vapor deposition (PVD) technique where a material is heated in a high vacuum until it evaporates. The resulting vapor then travels through the vacuum and condenses onto a cooler surface, or substrate, forming a uniform thin film. This process is also known as resistive evaporation because the heat is generated by passing a strong electrical current through a resistive element holding the material.

The effectiveness of thermal evaporation hinges on a simple principle: combining resistive heating with a high-vacuum environment. The vacuum is not just a container; it is essential for ensuring the evaporated atoms have a clean, unimpeded path to the substrate, which is the key to creating a pure, high-quality film.

The Core Principle: From Solid to Film

Thermal evaporation operates on a straightforward sequence of physical state changes, all carefully controlled within a specialized system. The process is governed by the interplay between heat and pressure.

The Role of Resistive Heating

The process begins by placing the source material, often in pellet or powder form, into a container known as an evaporation source or "boat." This boat is typically made of a refractory metal like tungsten or molybdenum.

An electrical current is passed through the boat, which heats up due to its own electrical resistance. As the temperature rises, the source material melts and its vapor pressure increases until it begins to sublimate or evaporate into a gas.

The Importance of the High Vacuum

The entire process takes place inside a sealed chamber pumped down to a high vacuum (e.g., pressures as low as 10⁻⁷ Torr).

This vacuum environment is critical. It removes air and other gas molecules that could collide with the evaporated source atoms, scatter them, or cause unwanted chemical reactions. A high vacuum ensures the atoms travel in a straight, line-of-sight path from the source to the substrate.

The Deposition Process

The evaporated atoms or molecules travel upward from the hot source. They eventually strike the much cooler substrate, which is strategically positioned above the source.

Upon contact with the cool substrate, the atoms rapidly lose their thermal energy, condense back into a solid state, and adhere to the surface. Over time, this atomic condensation builds up to form a precise and uniform thin film.

Anatomy of a Thermal Evaporation System

A functional thermal evaporation system is composed of several key components working in concert to create the necessary conditions for deposition.

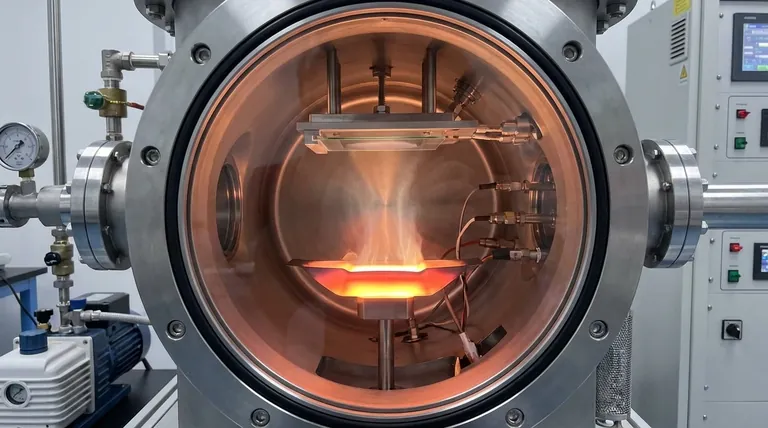

The Vacuum Chamber

This is the sealed enclosure that houses the entire process. It provides the isolated environment that can be pumped down to a high vacuum, protecting the process from atmospheric contamination.

The Evaporation Source

Located at the bottom of the chamber, this is the resistive element—often a boat, coil, or basket—that holds the source material and provides the heat for evaporation. The geometry of the source can influence the distribution of the deposited film.

The Substrate Holder

Positioned at the top of the chamber, this fixture holds the substrate (the material to be coated) in place, typically in an inverted position facing the source. Some holders can rotate to improve film uniformity.

The Pumping System

This is the heart of the system, responsible for creating and maintaining the high vacuum. Modern systems often use a Turbo Molecular Pump (TMP) backed by a roughing pump to quickly and cleanly achieve the required low pressures without the need for oil or extensive cooling.

Understanding the Trade-offs

Like any technical process, thermal evaporation has distinct advantages and limitations. Understanding them is key to deciding if it is the right method for a specific application.

Key Advantage: Simplicity and Cost

Thermal evaporation is one of the simplest and most cost-effective PVD methods. The equipment is less complex and generally less expensive than other techniques like sputtering or molecular beam epitaxy, making it highly accessible for research and small-scale production.

Limitation: Material Compatibility

The method works best for materials with relatively low evaporation points, such as gold, aluminum, chromium, and various organic compounds. It is not suitable for materials with very high melting points (refractory metals) or compounds that decompose at high temperatures instead of evaporating cleanly.

Limitation: Film Adhesion and Stress

Because the atoms arrive at the substrate with relatively low kinetic energy (just their thermal energy), the resulting films can sometimes have lower adhesion and density compared to films made with sputtering, where atoms are ejected with much higher energy. This can also result in higher internal stress within the film.

Limitation: Step Coverage

The line-of-sight nature of the process means it is excellent for coating flat surfaces. However, it provides poor "step coverage," meaning it cannot effectively coat the sidewalls of complex, three-dimensional microstructures or trenches on a substrate.

Making the Right Choice for Your Application

Choosing a deposition method depends entirely on your material, substrate, and the desired properties of the final film.

- If your primary focus is rapid research or coating simple metals: Thermal evaporation is an excellent choice due to its speed, simplicity, and low cost.

- If your primary focus is depositing high-melting-point materials or alloys: You should investigate alternative PVD methods like e-beam evaporation or sputtering.

- If your primary focus is coating complex 3D structures with high conformity: Methods like atomic layer deposition (ALD) or sputtering are better suited for the task.

- If your primary focus is achieving the highest possible film adhesion and density: Sputter deposition often provides superior results due to the higher energy of the depositing particles.

Ultimately, mastering thermal evaporation means understanding that its power lies in its controlled simplicity for a specific range of materials and applications.

Summary Table:

| Aspect | Key Takeaway |

|---|---|

| Process | Resistive heating in a high vacuum causes material to evaporate and condense on a substrate. |

| Best For | Materials with low evaporation points (e.g., gold, aluminum); simple, cost-effective coating. |

| Limitations | Poor step coverage for 3D structures; not suitable for high-melting-point materials or alloys. |

| Key Advantage | Simplicity, speed, and lower cost compared to other PVD methods like sputtering. |

Ready to enhance your research with precise thin films?

Thermal evaporation is a powerful, cost-effective method for depositing high-purity metal and organic films. Whether you are prototyping new devices or conducting fundamental materials research, having the right equipment is crucial for success.

KINTEK specializes in providing reliable lab equipment and consumables for all your deposition needs. From robust thermal evaporation systems to essential vacuum components, we supply the tools that help laboratories achieve consistent, high-quality results.

Let's discuss how we can support your project. Contact our experts today to find the perfect solution for your laboratory's specific challenges.

Visual Guide

Related Products

- Molybdenum Tungsten Tantalum Evaporation Boat for High Temperature Applications

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Evaporation Boat for Organic Matter

- Hemispherical Bottom Tungsten Molybdenum Evaporation Boat

- Aluminized Ceramic Evaporation Boat for Thin Film Deposition

People Also Ask

- What is the process of thin film evaporation? A Guide to High-Purity PVD Coating

- What is thermal evaporation method? A Simple Guide to Thin-Film Deposition

- What is the use of electron beam evaporation? Achieve High-Purity Thin Films for Demanding Applications

- Can gold be evaporated? Unlocking High-Purity Thin Film Deposition

- What is the principle of electron beam evaporation? A Guide to High-Purity Thin Film Deposition

- What temperature is physical vapor deposition? A Guide to PVD's Flexible Heat Range

- How does evaporation deposition work? A Guide to High-Purity Thin Film Coating

- What is an example of thermal evaporation? Creating Reflective Headlight Coatings and More