At its core, thermal evaporation is a process used to create ultra-thin films of material on a surface. It works by heating a source material inside a high-vacuum chamber until it evaporates, releasing atoms that travel through the vacuum and condense onto a cooler target object, known as a substrate. This technique is also called resistive evaporation because the heat is generated by passing an electrical current through a resistive element holding the material.

While appearing straightforward, thermal evaporation is a technique of trade-offs. Its simplicity and cost-effectiveness for depositing pure metals are balanced by limitations in coating complex shapes and controlling the composition of alloys.

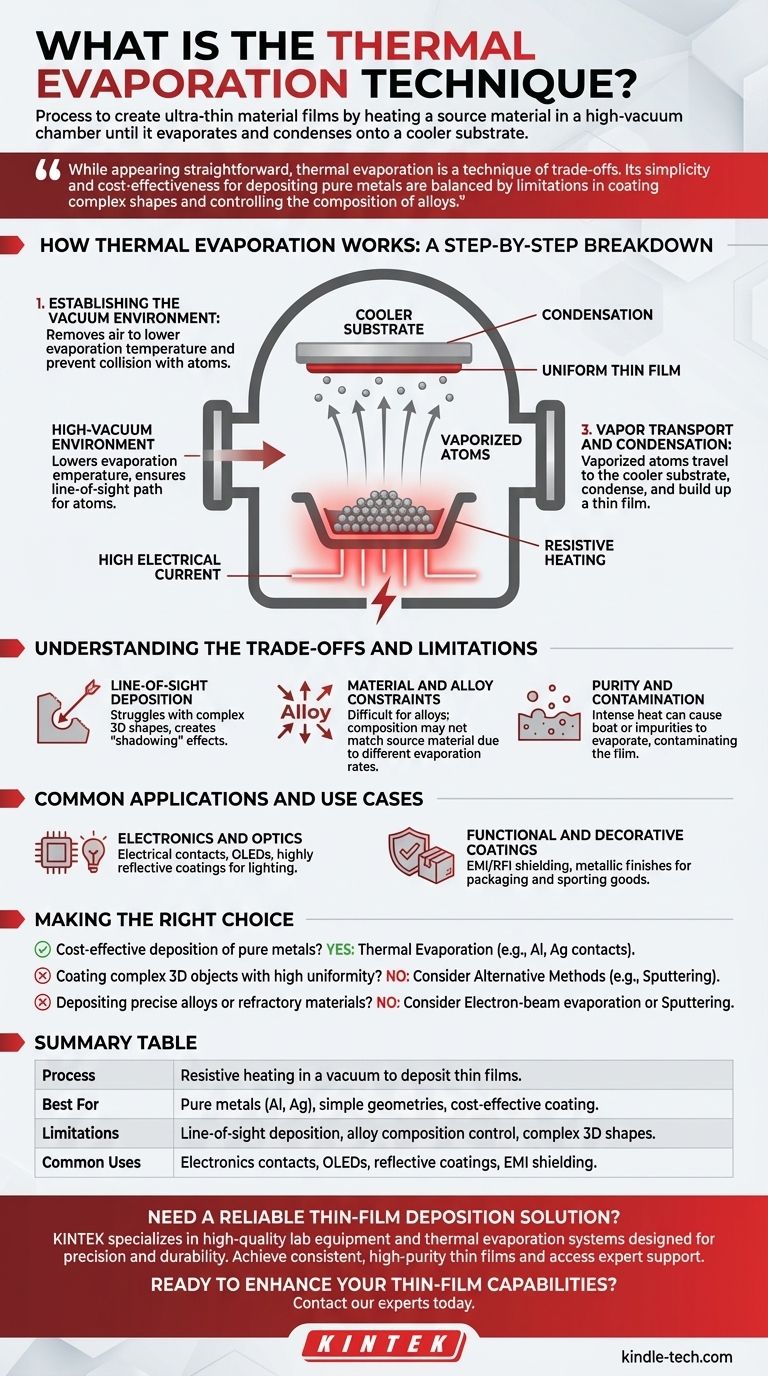

How Thermal Evaporation Works: A Step-by-Step Breakdown

The entire process hinges on controlling a physical transition—from solid to vapor and back to solid—within a highly controlled environment.

Step 1: Establishing the Vacuum Environment

Before any heating occurs, a vacuum pump removes almost all the air from a sealed chamber. This high-vacuum environment is critical for two reasons.

First, it dramatically lowers the temperature at which materials evaporate. Second, and more importantly, it removes air molecules that would otherwise collide with the vaporized atoms, ensuring they travel directly to the substrate in a line-of-sight path.

Step 2: Resistive Heating of the Source Material

The material to be deposited, often in the form of pellets or wire, is placed in a small, electrically resistive container called a "boat" or "basket." This boat is typically made from a refractory metal like tungsten.

A high electrical current is then passed through the boat. Due to its resistance, the boat heats up rapidly, transferring this thermal energy to the source material. The material melts and then begins to evaporate, releasing a vapor of atoms or molecules.

Step 3: Vapor Transport and Condensation

The vaporized atoms travel unimpeded through the vacuum until they strike the cooler substrate, which is strategically placed above or near the source.

Upon contact with the cooler surface, the atoms lose their energy and condense back into a solid state. Over time, these condensed atoms build up to form a uniform, thin film across the substrate's surface.

Understanding the Trade-offs and Limitations

No technique is perfect. Understanding the inherent limitations of thermal evaporation is key to using it effectively.

Line-of-Sight Deposition

Because the vapor travels in straight lines from the source, thermal evaporation struggles to coat complex, three-dimensional surfaces uniformly. Areas that are not in the direct line of sight of the source will receive little to no coating, creating a "shadowing" effect.

Material and Alloy Constraints

Thermal evaporation excels at depositing single elements like aluminum or silver, which have well-defined evaporation points.

However, depositing alloys (mixtures of metals) is very difficult. Different elements in an alloy often evaporate at different rates, meaning the composition of the resulting thin film will not match the composition of the source material. This requires complex systems with multiple sources and precise temperature control.

Purity and Contamination

While the vacuum removes most contaminants, the intense heat can cause the resistive boat itself to slowly evaporate, potentially contaminating the film. Likewise, any impurities in the source material will be evaporated and deposited along with the desired material.

Common Applications and Use Cases

Despite its limitations, the simplicity and speed of thermal evaporation make it a workhorse technology in many industries.

Electronics and Optics

This is the most common application area. It is used to create conductive metal layers for electrical contacts in devices like solar cells, OLED displays, and microelectromechanical systems (MEMS). It is also used to deposit highly reflective materials for light reflectors in automotive and medical lighting.

Functional and Decorative Coatings

Thermal evaporation is used to apply thin metallic layers for EMI/RFI shielding on electronic housings, preventing electromagnetic interference. It is also widely used for decorative purposes, such as creating the metallic finish on cosmetic packaging or sporting goods.

Making the Right Choice for Your Application

Use this framework to determine if thermal evaporation suits your goal.

- If your primary focus is cost-effective deposition of pure metals: Thermal evaporation is an excellent and highly efficient choice for applications like creating aluminum or silver contacts.

- If your primary focus is coating complex 3D objects with high uniformity: You should consider alternative methods like sputtering, which does not rely on a line-of-sight path.

- If your primary focus is depositing precise alloys or refractory (high-melting-point) materials: Techniques like electron-beam evaporation or sputtering offer far greater control over film composition and the ability to deposit more challenging materials.

By understanding its fundamental principles and inherent trade-offs, you can effectively leverage thermal evaporation as a powerful tool for thin-film engineering.

Summary Table:

| Aspect | Details |

|---|---|

| Process | Resistive heating in a vacuum to deposit thin films |

| Best For | Pure metals (Al, Ag), simple geometries, cost-effective coating |

| Limitations | Line-of-sight deposition, alloy composition control, complex 3D shapes |

| Common Uses | Electronics contacts, OLEDs, reflective coatings, EMI shielding |

Need a Reliable Thin-Film Deposition Solution?

Thermal evaporation is a powerful technique, but choosing the right equipment is critical for your lab's success. KINTEK specializes in high-quality lab equipment and consumables, including thermal evaporation systems designed for precision and durability.

We help you:

- Achieve consistent, high-purity thin films for your R&D or production needs.

- Select the right configuration—whether you're working with pure metals for electronics or decorative coatings.

- Access expert support to optimize your deposition process and overcome technical challenges.

Ready to enhance your thin-film capabilities? Contact our experts today to discuss your specific application and find the perfect thermal evaporation solution for your laboratory.

Visual Guide

Related Products

- Molybdenum Tungsten Tantalum Evaporation Boat for High Temperature Applications

- Hemispherical Bottom Tungsten Molybdenum Evaporation Boat

- Aluminized Ceramic Evaporation Boat for Thin Film Deposition

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- What is the evaporation process in semiconductors? A Guide to Thin Film Deposition

- What is thermal evaporation technique thin film deposition? A Guide to Simple, Cost-Effective PVD

- What is thermal effect via evaporation? A Simple Guide to Thin-Film Deposition

- What is the widely used boat made of in thermal evaporation? Choosing the Right Material for High-Purity Deposition

- What is the difference between sputtering and thermal evaporation? Choose the Right PVD Method for Your Thin Film