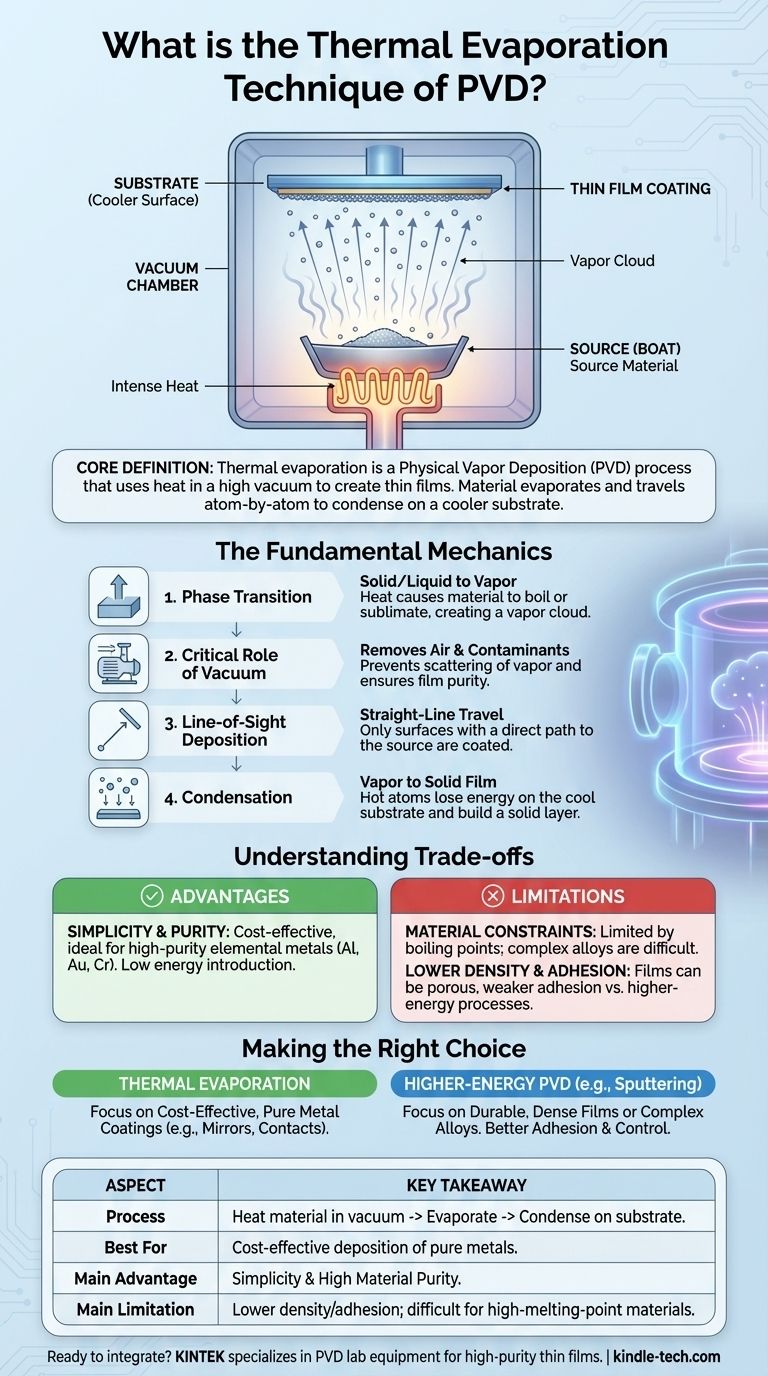

At its core, the thermal evaporation technique is a Physical Vapor Deposition (PVD) process for creating exceptionally thin films. It works by heating a source material inside a high vacuum chamber until it evaporates into a vapor. This vapor then travels through the vacuum and condenses onto a cooler target surface, known as a substrate, forming a solid, uniform coating.

Thermal evaporation is a straightforward deposition method that uses heat and a vacuum to transport material atom-by-atom. The process relies on a fundamental principle: a material heated in a vacuum will travel in a straight line until it hits a cooler surface, where it will stick and build a new layer.

The Fundamental Mechanics of Thermal Evaporation

To truly understand this technique, it's essential to break down the process into its four critical stages. Each stage plays a precise role in the final quality and characteristics of the thin film.

Phase Transition: From Solid to Vapor

The process begins with the source material, which can be a solid or liquid, placed in a holder (often called a "boat"). This material is heated intensely.

The heat causes the material to either melt and then boil or, for some materials, sublimate directly from a solid into a gaseous state. This creates a cloud of vaporized atoms or molecules.

The Critical Role of the Vacuum

This entire process is conducted in a high vacuum environment, which is not merely empty space but an active component of the technique.

The vacuum serves two primary purposes. First, it removes air molecules that would otherwise collide with the vapor atoms, scattering them and preventing them from reaching the substrate. Second, it eliminates contaminants like oxygen and water vapor, which could react with the hot vapor and compromise the purity of the final film.

Line-of-Sight Deposition

Once vaporized, the atoms travel away from the source in straight lines, a characteristic known as line-of-sight travel.

This means that only the surfaces with a direct, unobstructed path to the source will be coated. Any part of the substrate shadowed from the source will receive little to no deposition.

Condensation: From Vapor to Solid Film

The substrate is strategically placed within the chamber and is kept at a significantly lower temperature than the vapor source.

When the hot vapor atoms strike the cool substrate surface, they rapidly lose their thermal energy. This energy loss causes them to condense back into a solid state, meticulously building up the thin film layer by layer.

Understanding the Trade-offs

While powerful, thermal evaporation is not the universal solution for all thin-film applications. Understanding its inherent advantages and limitations is crucial for making an informed decision.

Advantage: Simplicity and Purity

Thermal evaporation is often considered one of the simpler and more cost-effective PVD methods. It is particularly effective for depositing high-purity films of elemental metals like aluminum, gold, or chromium, as the process introduces very little energy or contamination.

Limitation: Material Constraints

The technique is limited by the boiling point of the source material. Materials with extremely high melting points are difficult and energy-intensive to evaporate. Furthermore, depositing complex alloys can be challenging, as the different elements in the alloy may evaporate at different rates, changing the composition of the final film.

Limitation: Film Adhesion and Density

Compared to higher-energy processes like sputtering, films created by thermal evaporation can sometimes exhibit lower density and weaker adhesion to the substrate. The deposited atoms arrive with relatively low energy, which can result in a more porous film structure.

Making the Right Choice for Your Goal

Selecting the correct PVD method depends entirely on the desired properties of your final film and your operational constraints.

- If your primary focus is cost-effective coating with pure metals: Thermal evaporation is an excellent and straightforward choice, especially for applications like mirror coatings or simple electrical contacts.

- If your primary focus is creating durable, dense films or complex alloys: You should consider higher-energy PVD methods like sputtering, which provide superior adhesion and more precise control over the film's final composition.

Ultimately, understanding this balance between simplicity and film properties is the key to leveraging thermal evaporation effectively in your project.

Summary Table:

| Aspect | Key Takeaway |

|---|---|

| Process | Heats a material in a vacuum until it evaporates and condenses on a substrate. |

| Best For | Cost-effective deposition of pure metals (e.g., Aluminum, Gold). |

| Main Advantage | Simplicity and high material purity. |

| Main Limitation | Lower film density/adhesion vs. sputtering; challenging for high-melting-point materials. |

Ready to integrate thermal evaporation into your lab workflow? KINTEK specializes in providing the precise lab equipment and consumables you need for reliable PVD processes. Whether you're coating mirrors or creating electrical contacts, our expertise ensures you get the right solution for high-purity thin films. Contact our experts today to discuss your project requirements!

Visual Guide

Related Products

- Molybdenum Tungsten Tantalum Evaporation Boat for High Temperature Applications

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Hemispherical Bottom Tungsten Molybdenum Evaporation Boat

People Also Ask

- What are the drawbacks of thermal evaporation? Understanding the Limitations for High-Performance Applications

- What is vacuum thermal evaporation? A Guide to High-Purity Thin Film Deposition

- What is the difference between sputtering and thermal evaporation? Choose the Right PVD Method for Your Thin Film

- What is thermal evaporation technique thin film deposition? A Guide to Simple, Cost-Effective PVD

- What is the widely used boat made of in thermal evaporation? Choosing the Right Material for High-Purity Deposition