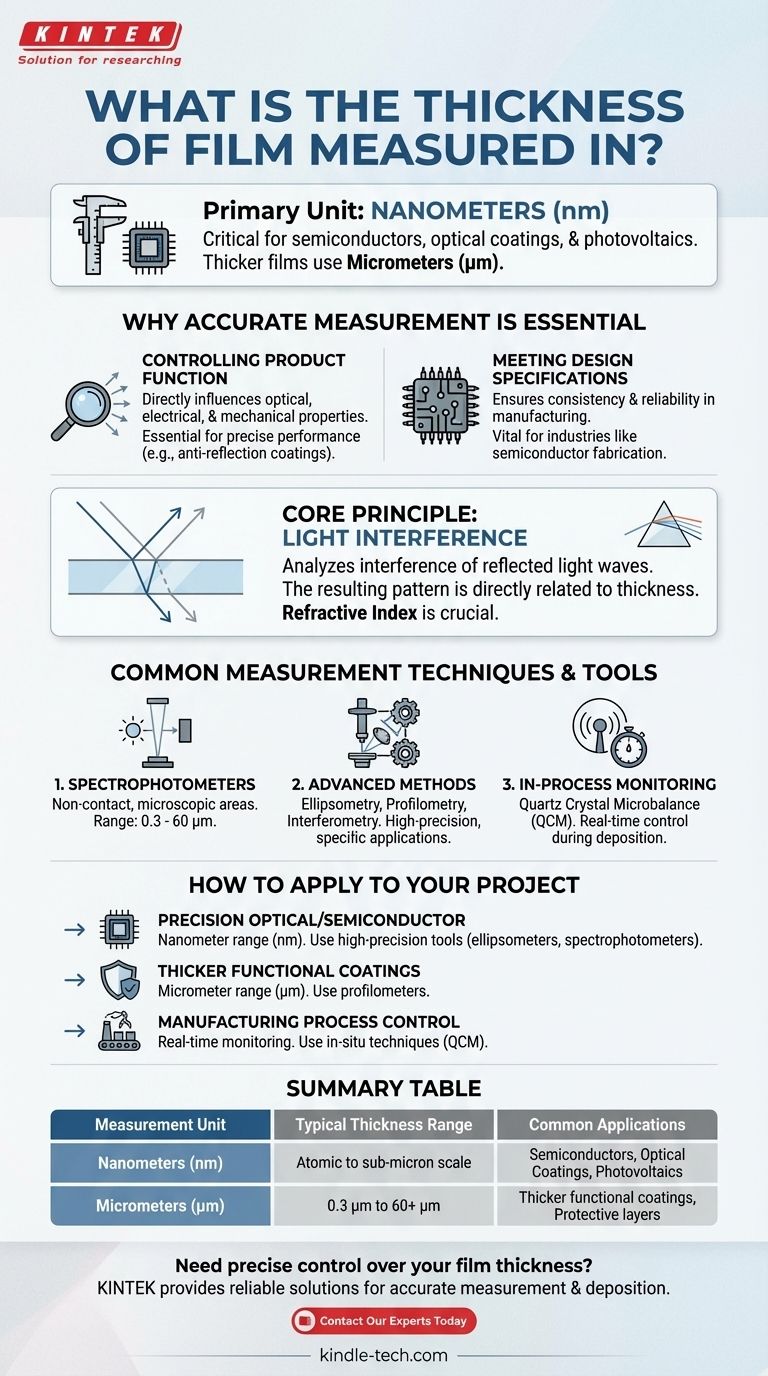

In most technical applications, the thickness of a thin film is measured in nanometers (nm). This unit is standard for materials used in semiconductors, optical coatings, and photovoltaics, where precision at the atomic level is critical for performance. For thicker films or coatings, measurements may also be expressed in microns (µm).

The core principle to understand is that the choice of measurement unit—and the technique used to obtain it—is dictated entirely by the film's intended function and its physical thickness. While nanometers are common for "thin" films, the broader context involves a range of tools and scales.

Why Accurate Thickness Measurement is Essential

Controlling Product Function

The thickness of a film is not an arbitrary dimension; it is a critical design parameter. It directly influences a product's optical, electrical, and mechanical properties.

For example, in anti-reflection coatings on lenses, the thickness must be precisely controlled to cancel out specific wavelengths of light. Any deviation compromises its function.

Meeting Design Specifications

Manufacturing processes require tight quality control to ensure consistency and reliability. Measuring film thickness verifies that the final product meets its design specifications and will perform as expected.

This is fundamental in industries like semiconductor fabrication, where even a slight variation in a dielectric layer can render a microchip useless.

The Core Principle of Measurement: Light Interference

How It Works

Many non-contact measurement tools operate by analyzing the interference of light. A beam of light is directed at the film, and reflections occur at both the top surface and the bottom interface.

These two reflected light waves interfere with each other. The resulting pattern of peaks and valleys in the light's spectrum is directly related to the thickness of the film.

The Role of Refractive Index

To calculate the final thickness from the interference pattern, you must know the material's refractive index. This property describes how light travels through that specific material.

Because every material has a different refractive index, it is a crucial variable in the calculation for ensuring an accurate measurement.

Common Measurement Techniques and Tools

Spectrophotometers

Spectrophotometers are a common non-contact tool for measuring film thickness. They are highly effective for microscopic sampling areas.

These instruments can typically measure layer thicknesses in the range of 0.3 to 60 micrometers (µm), making them versatile for both thin and relatively thick films.

Other Advanced Methods

Beyond spectrophotometry, several other high-precision techniques are used, including ellipsometry, profilometry, and interferometry. Each offers unique advantages depending on the material and application.

In-Process Monitoring

For real-time control during the manufacturing process, techniques like quartz crystal microbalance (QCM) sensors are used. These tools measure film thickness as it is being deposited, allowing for immediate adjustments.

How to Apply This to Your Project

A clear understanding of your goal is the most important factor in selecting the right measurement approach.

- If your primary focus is on precision optical coatings or semiconductor layers: You will be working in the nanometer (nm) range and require high-precision tools like ellipsometers or spectrophotometers.

- If your primary focus is on thicker functional coatings (e.g., protective layers): Measurements in micrometers (µm) are often sufficient, and tools like profilometers may be more practical.

- If your primary focus is on manufacturing process control: In-situ techniques like QCM are essential for real-time monitoring and adjustment during deposition.

Ultimately, mastering film thickness measurement is about translating a physical dimension into functional control.

Summary Table:

| Measurement Unit | Typical Thickness Range | Common Applications |

|---|---|---|

| Nanometers (nm) | Atomic to sub-micron scale | Semiconductors, Optical Coatings, Photovoltaics |

| Micrometers (µm) | 0.3 µm to 60+ µm | Thicker functional coatings, Protective layers |

Need precise control over your film thickness? KINTEK specializes in lab equipment and consumables, providing reliable solutions for accurate thickness measurement and deposition. Whether you're working with nanometer-scale semiconductors or thicker protective coatings, our expertise ensures your lab achieves consistent, high-quality results. Contact our experts today to discuss your specific application and find the perfect tool for your needs!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Molybdenum Tungsten Tantalum Evaporation Boat for High Temperature Applications

- Aluminized Ceramic Evaporation Boat for Thin Film Deposition

- Hemispherical Bottom Tungsten Molybdenum Evaporation Boat

People Also Ask

- What is the difference between PECVD and sputter? Choose the Right Thin-Film Deposition Method

- How does PECVD work? Enable Low-Temperature, High-Quality Thin Film Deposition

- How does RF power create plasma? Achieve Stable, High-Density Plasma for Your Applications

- What is plasma enhanced chemical vapor deposition PECVD equipment? A Guide to Low-Temperature Thin Film Deposition

- What is plasma activated chemical vapour deposition method? A Low-Temperature Solution for Advanced Coatings